10A-30

ENGINE AND CYLINDER BLOCK ASSEMBLY

Sump: Removal - Refitting

F9Q

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

a Position the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

a Remove:

-the engine undertray bolts,

-the engine undertray.

a Drain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-40) .

a Remove the engine tie-bar (see 19D, Engine

mounting, Lower engine tie-bar: Removal - Refit-

ting, page 19D-33) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

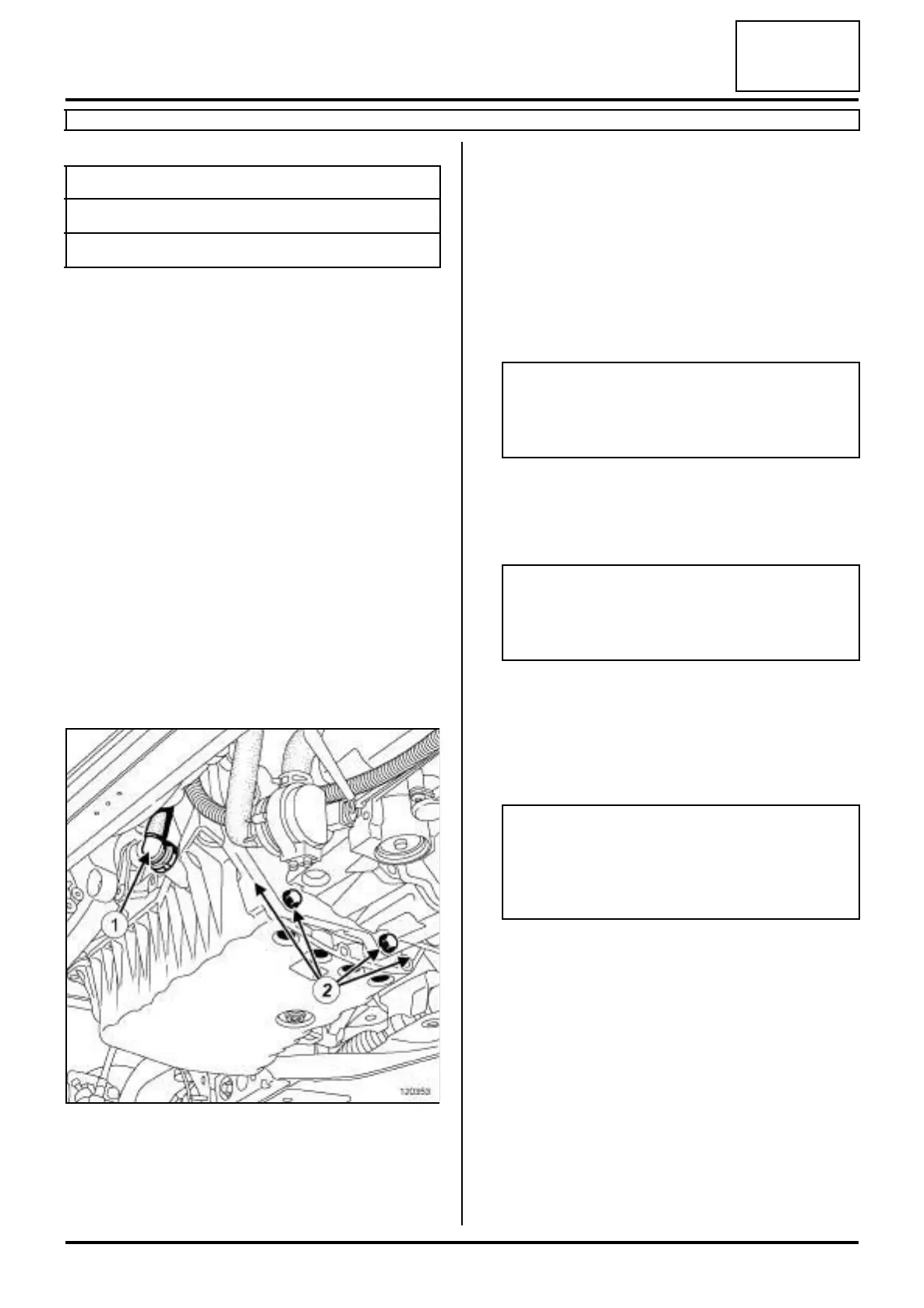

a Disconnect the oil vapour rebreathing pipe (1) from

the sump.

a Remove:

-the sump bolts (2) on the gearbox,

- the sump bolts on the cylinder block,

- the sump,

- the sump seal.

REFITTING

I - REFITTING PREPARATION OPERATION

a Always replace the sump gasket.

a Clean the cylinder block joint face using SUPER

CLEANING AGENT FOR JOINT FACES (see Ve-

hicle: Parts and ingredients for the repairwork)

(04B, Consumables - Products).

a Use SURFACE CLEANER (see Vehicle: Parts

and ingredients for the repairwork) (04B, Consu-

mables - Products) to degrease:

- the sump joint face if it is to be reused,

- the cylinder block gasket face.

Tightening torquesm

sump bolts (A) to (F) 18 N.m

sump bolts (1) to (18) 15 N.m

120353

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

WARNING

To ensure proper sealing, the gasket surfaces

must be clean, dry and not greasy (avoid any fin-

ger marks).

WARNING

Applying excess sealant could cause it to be

squeezed out when parts are tightened. A mix-

ture of sealant and fluid could damage certain

components (engine, radiator, etc.).

Loading...

Loading...