Troubleshooting

116

Doc No: UMAN\FL\0110

Rev. No.: 1.02B

8.1 Troubleshooting Procedure

1. Pay special attention during the troubleshooting to minimize the risk of electrical shock.

2. Turn off power immediately if the FlexiLogics unit or related equipment is emitting smoke

or odor. Operation under such situation can cause fire or electrical shock.

3. Turn off power before removing or replacing units, modules, terminal blocks or wires.

Failure to do so can cause electrical shock or damage to the PLC and related

equipment.

4. Contact REPL for repairing if the FlexiLogics basic unit or related equipment is failed.

REPL will not guarantee proper operation nor safety for unauthorized repairing.

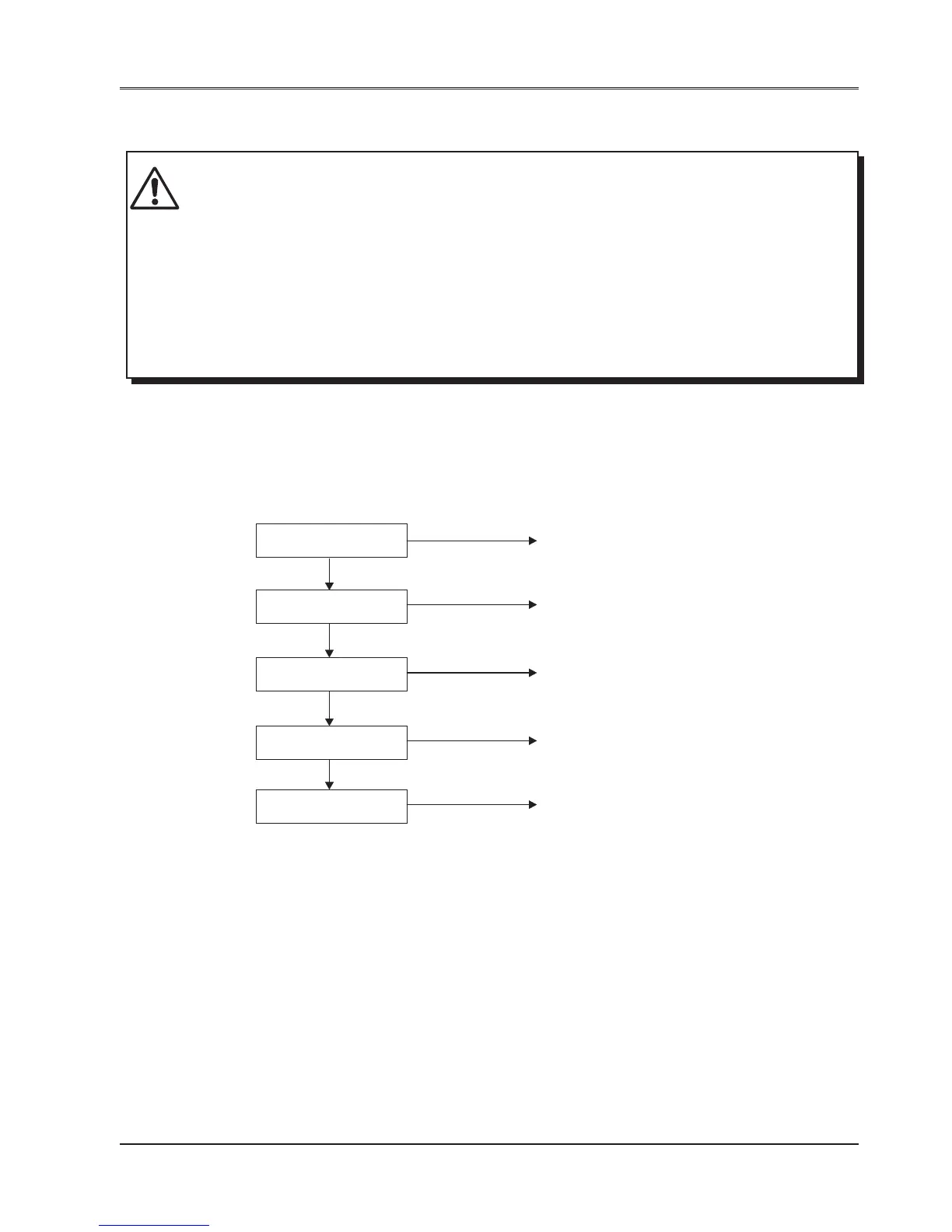

If a trouble occurs, determine whether the cause lies in the mechanical side or in the control system (PLC) side. A

problem may cause a secondary problem, therefore, try to determine the cause of trouble by considering the whole

system.

If the problem is found in the FlexiLogics base PLC model, check the following points:

CAUTION

PWR (power) LED Follow the procedure in

Power supply check

Lit

RUN LED Follow the procedure in

CPU check

Lit

User program Follow the procedure in

Program check

Normal operation

Input operation Follow the procedure in

Input check

Normal operation

Output operation Follow the procedure in

Output check

Not lit

Not lit

Not normal

Not normal

Not normal

Loading...

Loading...