REYMSA COOLING TOWERS, INC.

www.reymsa.com

54

B. START-UP

Before starting the pumps and running water through the Tower, the piping system should be flushed out to

remove any debris which may have gotten into the pipe during installation. Also, inspect the bottom section

of the Tower and remove any debris, which may have accumulated during installation. For Start-up, proceed

as follows:

B.1 FILLING SYSTEM WITH WATER

A. Open make-up valve(s) and allow basin(s) and piping to fill to the Tower overflow level.

B. Check all flanged connections and piping for leaks.

C. Bleed air from piping by opening purge valve at pump until water flows out in a steady stream without

interruption.

D. Close purge valve.

E. Fill completely the Tower’s basin with water (without overflowing it).

B.2 CONTROLLING WATER LEVEL

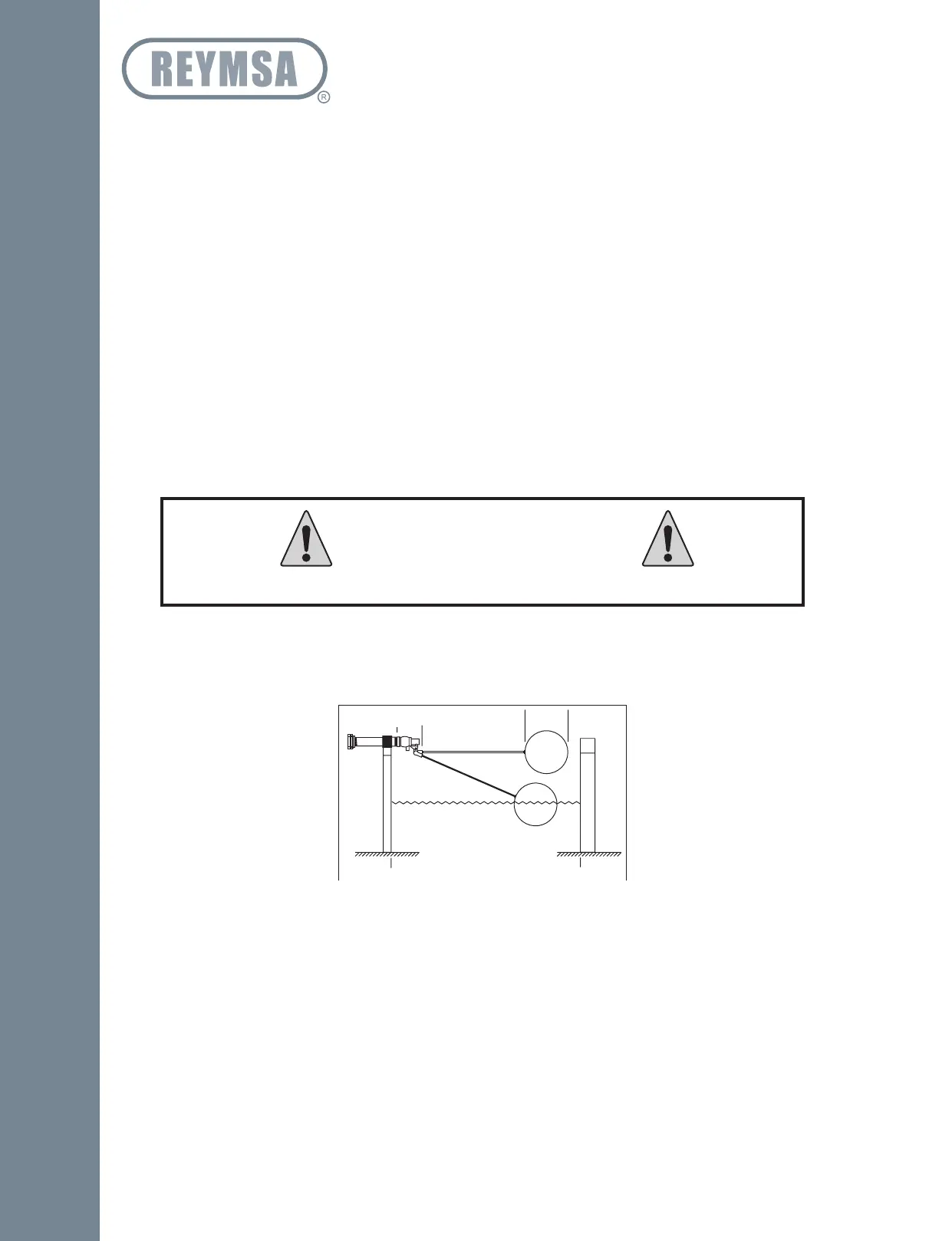

REYMSA Cooling Towers provides a mechanical float valve as standard (see Figure B-1 or refer to “APPENDIX

B: WATER MAKE-UP FLOAT VALVE”); an electric valve for automatic flow control is offered as optional. Use

the following instructions to adjust the make-up water mechanical float valve on the basin section of the

Tower to produce the highest water level without overflowing the Tower.

A. Remove Air Inlet Louvers within the area where float valve(s) is located.

B. Close make-up valve(s).

C. Check basin water level. The proper water level should be within the range of the operating level.

D. Loosen the nut on the adjustment bolt, and then loosen the bolt itself. Do not remove the bolt.

E. Rotate arm and stem to desired water level.

F. Tighten adjustment bolt and nut.

G. Restore water supply and verify that the water level is at the desired operating level.

H. Reinstall Air Inlet Louvers.

Figure B-1: Float valve installation

If inlet pressure to the mechanical float valve exceeds 50 psi.

WARRANTY VOID

Start-Up

Loading...

Loading...