REYMSA COOLING TOWERS, INC.

www.reymsa.com

64

C.3.4. CORROSION

Corrosion is a process of metal dissolution usually by oxidation; this process provokes degradation on the

metal surface, creating pits or even holes on it. Corrosion of system components shortens its life, reducing

operational reliability. However, since REYMSA Cooling Towers are constructed of FRP, corrosion is not an

issue for the tower.

C.3.5. AIR POLLUTION

A Cooling Tower draws air as a part of its operation, it can attract a variety of particles on it, interfering

with its performance. Do not locate the unit close to smoke stacks, discharge ducts, vents or gas flue exhausts.

C.4 MAKE-UP WATER REQUIREMENTS

Make-up water is added to compensate for the volume of water lost throughout evaporation, drift and

blowdown. Evaporation accounts for the largest loss of water from a water cooling system and is independent

of system’s flow for typical operating temperatures. To achieve one ton of cooling, a Tower will evaporate

about 1% of process water each minute, per every 10°F range.

As this water evaporates, it leaves behind any dissolved solids it may have been carrying. If allowed to

go unchecked, these solids will eventually precipitate out or scale the heat transfer surfaces. To aid in

controlling dissolved solids a portion of the process water must be discharged from the system and replaced

by fresh make up water thus diluting the remaining process water. Blow-down or bleed are common names

given to this discharge.

Determining the amount of blow-down required is heavily influenced by the quality of water used for

make up. As the dissolved solids content of the make up water increases the need for higher blow-down

rates will also increase. Cycles of concentration are used in establishing the blow-down rate. The value of

the cycles of concentration is the ratio between the process water concentration of dissolved solids and the

make up water concentration of dissolved solids. A chemical analysis by a water treatment professional is

the recommended method for determining the optimum cycles of concentration for the Cooling Tower water.

Water is also lost from the Cooling Tower itself in the form of liquid droplets, which become entrained in

the Cooling Tower air stream and discharged with it. Known as drift, the amount of water blown out of the

Tower is dependent on the Tower’s eliminators and the flow through the Tower. Generally 0.001% of the

Tower flow rate may be used as an estimate for drift in a counter-flow Tower.

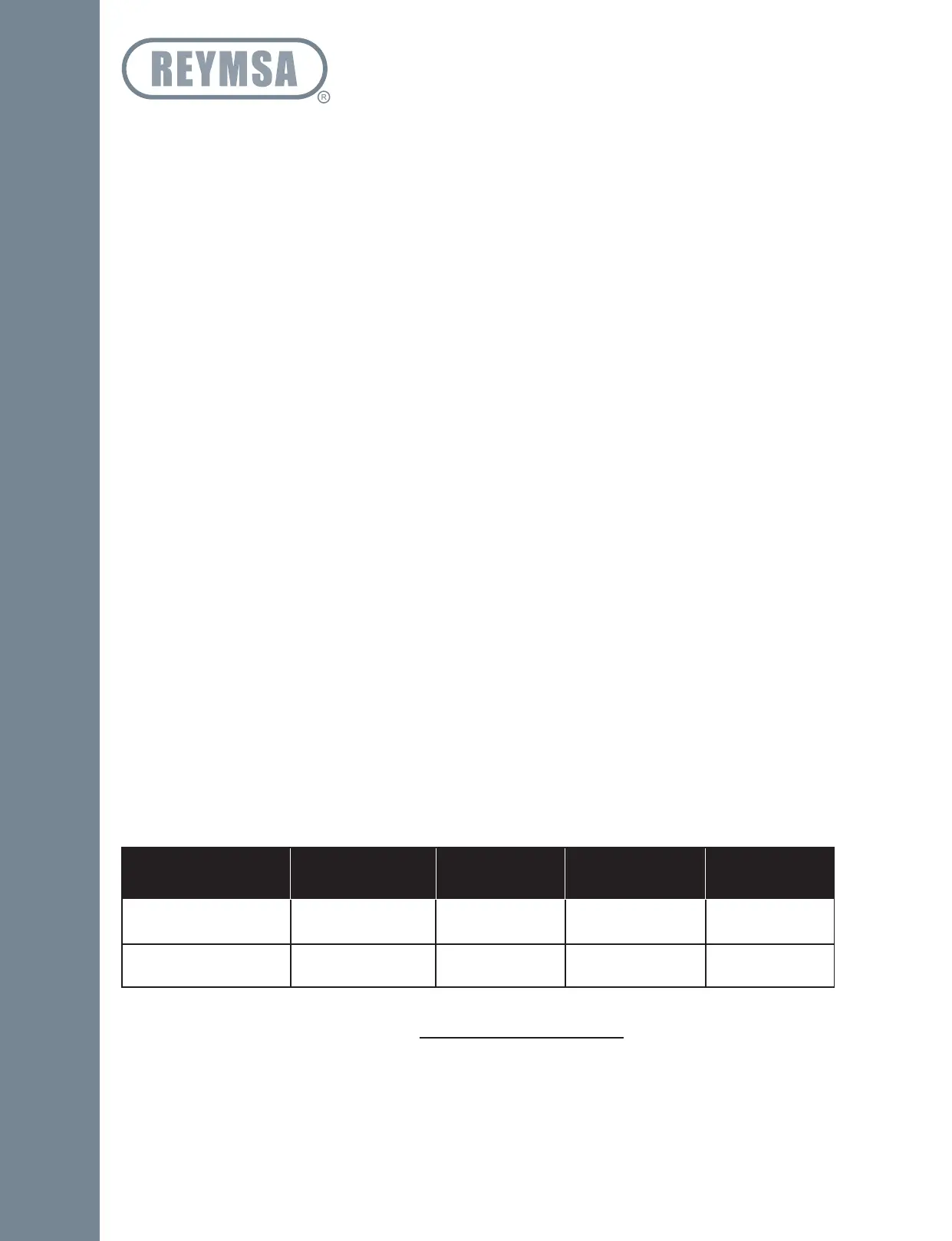

In Table C-4, there is an example which may be used for estimating water usage in a typical fully loaded

system, with a 10°F temperature drop through the Tower. Flows are represented as a percentage of the

total flow through the Cooling Tower.

CYCLES OF

CONCENTRATION (CC)

EVAPORATION DRIFT PURGE MAKE-UP

2 1.0% 0.001% 0.999% 2.0%

3 1.0% 0.001% 0.499% 1.5%

Table: C-4 Cycles of concentration

% PURGE =

% EVAPORATION - % DRIFT

CYCLES OF CONCENTRATION - 1

Operation

Loading...

Loading...