REYMSA COOLING TOWERS, INC.

www.reymsa.com

76

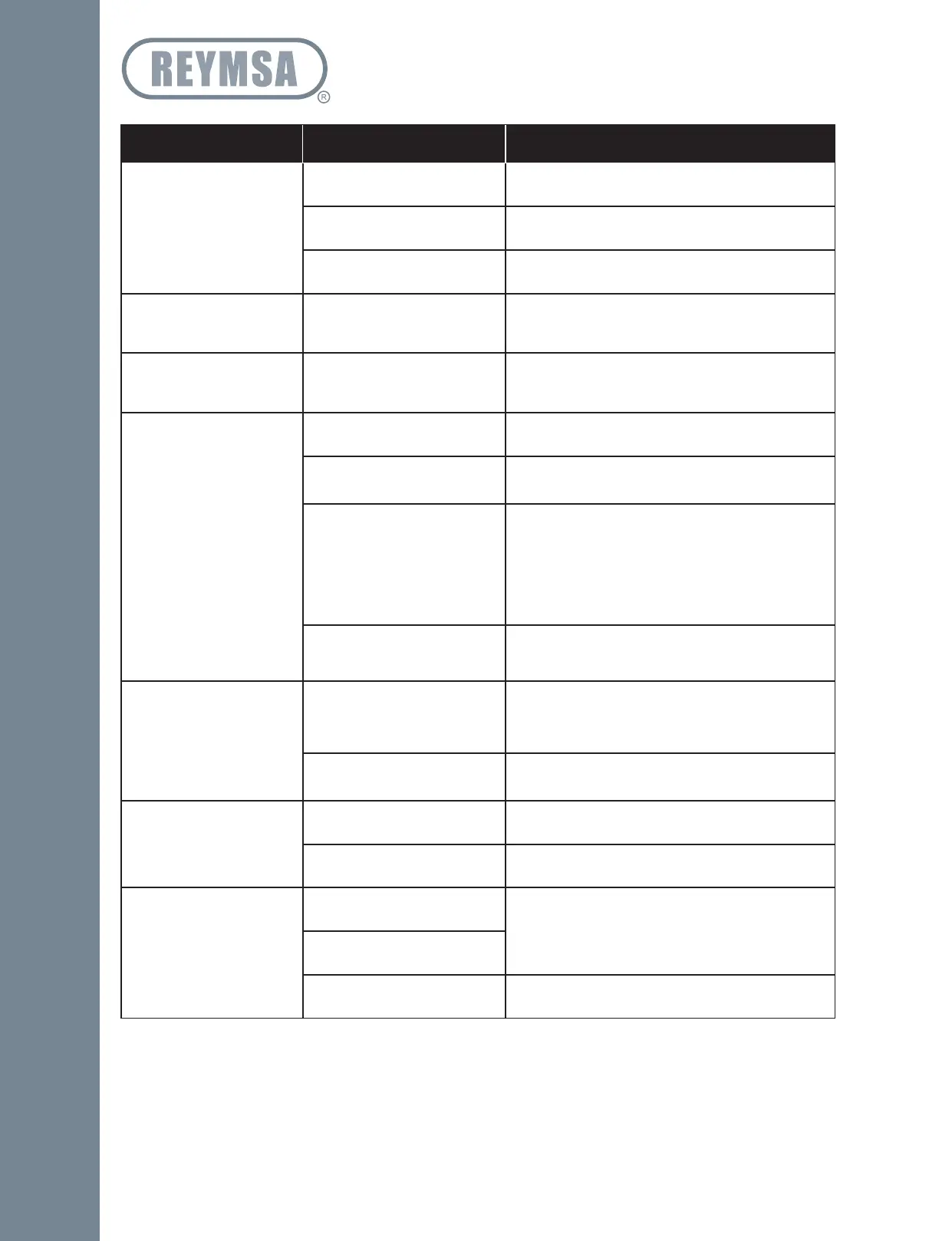

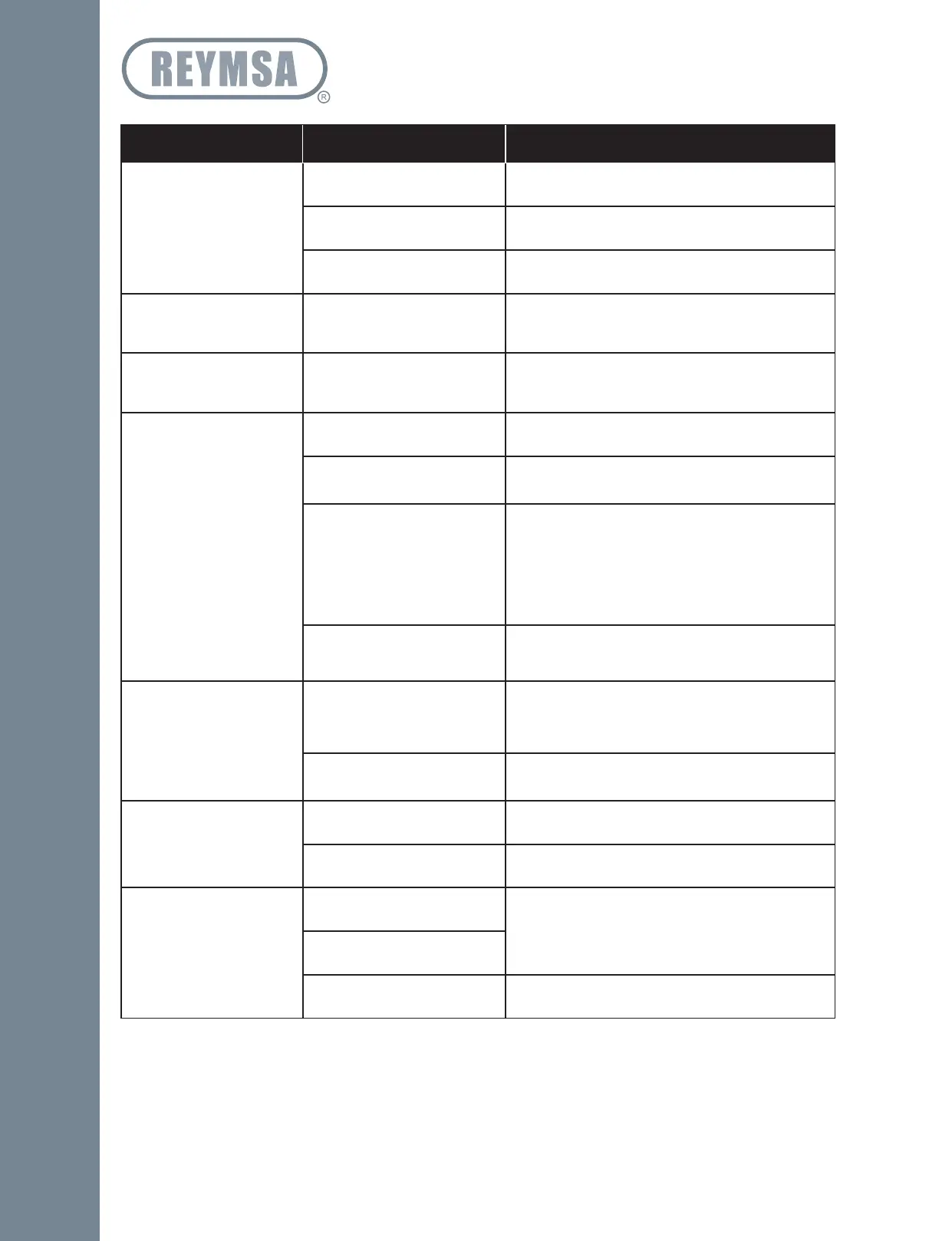

PROBLEM / SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

The water is not falling

uniformly from the fill.

Clogged nozzle(s) Clean nozzles and replace as required

Low pressure at the water inlet Check pressure at the inlet and adjust as necessary

(while pumps are running)

Obstructed fill media Inspect and perform cleaning and maintenance if

required (see section “D.2 BASIN” of this manual)

Water leaking around the

access door

Improperly installed or

damaged gasket

Ensure that the bolts attaching the access door are

all in place and are properly tightened. If leakage

does not stop it will be necessary to take the Tower

out of service to inspect or replace the gasket

Water leaking from a

crack in the fiberglass

The Tower was not handled

properly during installation

or some other impact has

occurred

Call your local REYMSA Representative for advice

Water leaking through the

air inlet louvers

High water operating level Adjust the water make-up valve to a lower

operating level

System water is overflowing

the Tower when pumps are

stopped

Check piping height, grade and check valve in

pump discharge

Excessive water flow through

the Tower

The Tower should have been installed with a

water pressure gauge and throttling valve at the

water inlet. Check the pressure reading at the

Tower inlet and ensure that is does not exceed

the recommended pressure for each Tower. Use

the throttling valve to adjust the pressure. Cooling

Towers are designed to operate between 2 psi and

10 psi at the Tower inlet, REYMSA recommends to

work between 4-8 psi

Damaged or reversed louvers Replace the louvers if damaged. Confirm that

louvers are installed properly, parts facing inward

and downward.

Excessive Drift

Excessive water flow through

the Tower

The Tower should have been installed with a water

pressure gauge and a throttling valve at the Tower

inlet. Check the pressure reading at the inlet and

ensure that it does not exceed recommendations.

Use the throttling valve to adjust the pressure

Drift Eliminators are

damaged, are not lying flat or

improperly aligned

Inspect the drift eliminators to ensure that there is

no damage, that they are lying flat and that there

are no gaps between them

Excessive accumulation of

debris or dirt in the bottom

of the basin

Unsatisfactory water treatment Remove the debris and dirt while the Tower is out of

service

Excessive airborne

contamination

Consider filtration

Unusual noise or vibration in

the Gear Reducer (RTG &

RTGM)

Misalignment Stop operation of the tower. Make sure that gear

drive, drive shaft and motor are bolted and tighten

Torsional Vibrations

Unstable support Make sure the motor support is secured

Trouble-Shooting

Loading...

Loading...