Rockwell Automation Publication 2080-UM002L-EN-E - November 2021 275

Appendix F PID Function Blocks

Gains Input PID_GAINS

Gains of PID for controller.

Use the PID_GAINS data type to configure the Gains parameter.

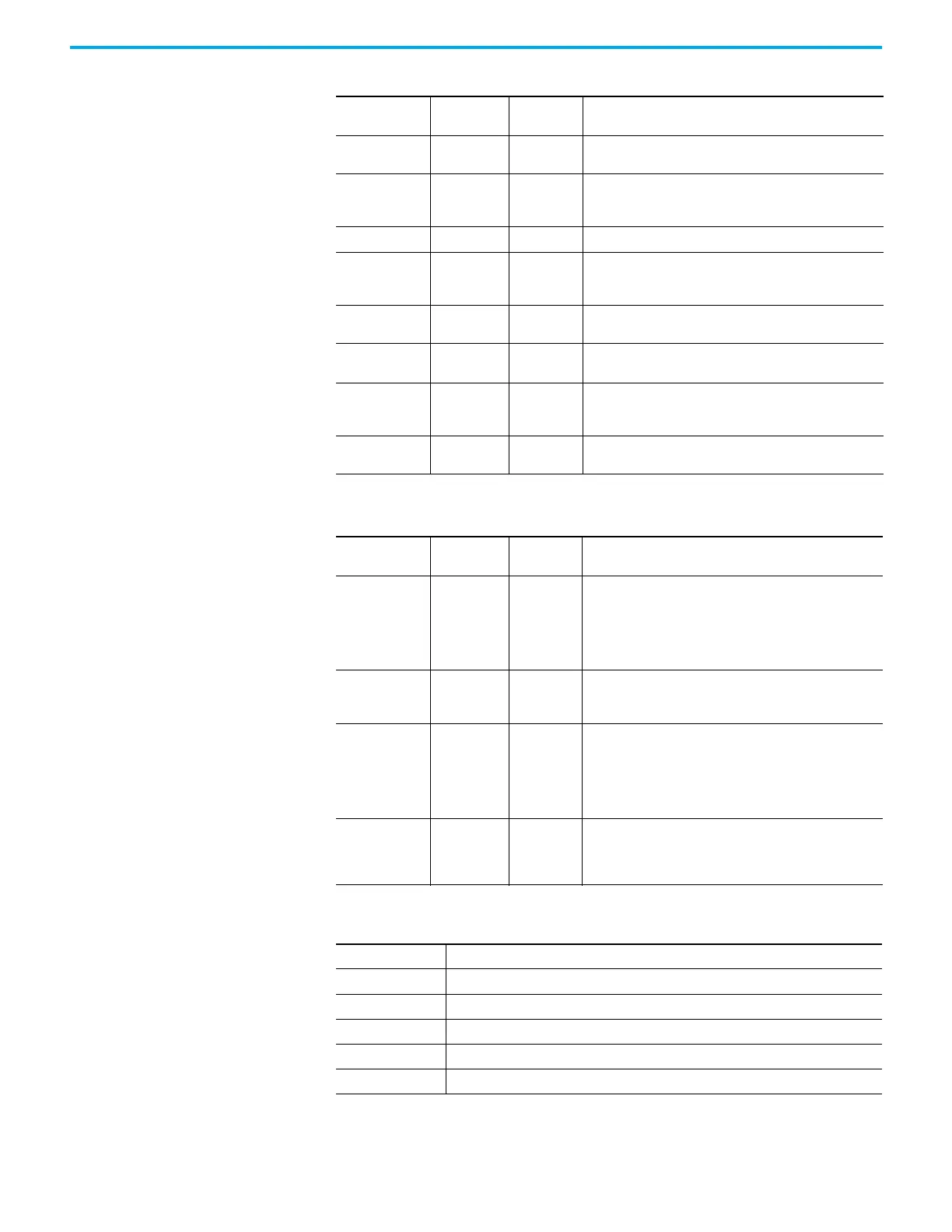

Control Input BOOL

Control direction of the process:

TRUE = Direct acting, such as Cooling.

FALSE = Reverse acting, such as Heating.

Llnit Input BOOL Reserved for future use.

Active Output BOOL

Status of the PID controller:

TRUE = PID state is running.

FALSE = PID state is stopped.

CV Output REAL

The control value output.

If any error occurred, CV is 0.

AbsoluteError Output REAL

Absolute error is the difference between process value (PV) and

setpoint (SV) value.

Error Output BOOL

Indicates the existence of an error condition.

TRUE = PID has an error.

FALSE = PID has no errors.

ErrorID Output USINT

A unique numeric that identifies the error. The errors are

defined in PID error codes.

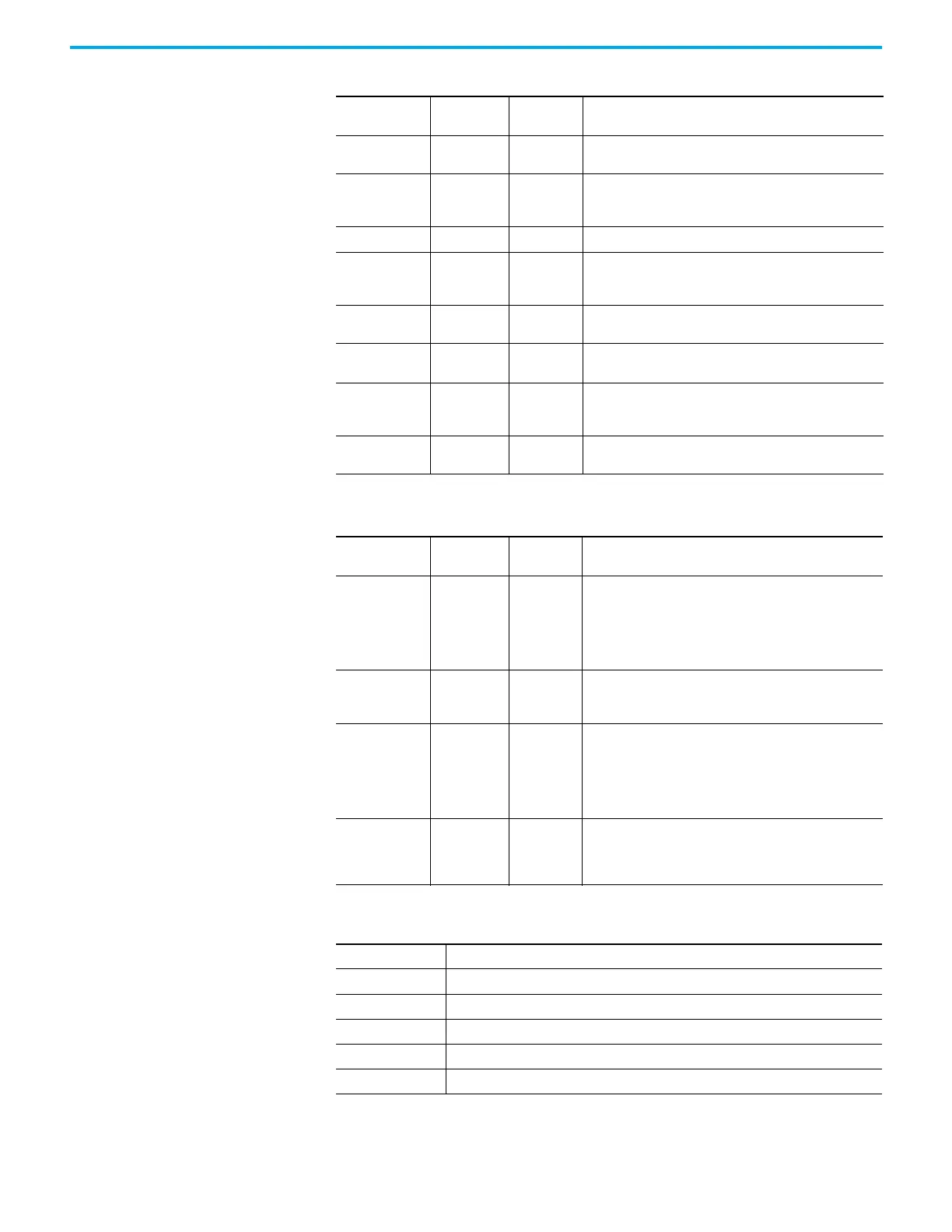

Table 59 - GAIN_PID Data Type

Parameter

Parameter

Type

Data Type Description

Kc Input REAL

Controller gain for PID.

Proportional and Integral are dependent on this gain (>=

0.0001).

Increasing Kc improves response time but also increases

overshoot and oscillation of the PID.

If Kc is invalid, an error occurs.

Ti Input REAL

Time integral constant in seconds (>= 0.0001).

Increasing Ti decreases overshoot and oscillation of the PID.

If Ti is invalid, an error occurs.

Td Input REAL

Time derivative constant in seconds (>= 0.0).

When Td equals 0, then there is no derivative action and PID

becomes a PI controller.

Increasing Td reduces the overshot and removes the oscillation

of the PID controller.

If Td is invalid, an error occurs.

FC Input REAL

Filter constant (>= 0.0).

Recommended range for FC is 0...20.

Increasing FC smooths the response of the PID controller.

If FC is invalid, an error occurs.

Table 60 - PID Error Codes

Error Code Description

0 PID is working normally.

1 Kc is invalid.

2 Ti is invalid.

3 Td is invalid.

4 FC is invalid.

Table 58 - PID Arguments (Continued)

Parameter

Parameter

Type

Data Type Description

Loading...

Loading...