98 Rockwell Automation Publication 2080-UM002L-EN-E - November 2021

Chapter 7 Motion Control

MC_Engine_Diag Data Type

The MC_Engine_Diag data type contains diagnostic information on the

embedded motion engine. It can be monitored in debug mode through the

Connected Components Workbench software when the motion engine is

active, or through the user application as part of user logic. It can also be

monitored remotely through various communication channels.

One MC_Engine_Diag instance is created automatically in the Connected

Components Workbench software when the user adds the first motion axis in

the motion configuration. This instance is shared by all user-configured

motion axes.

Function Block and Axis

Status Error Codes

All motion control function blocks share the same ErrorID definition.

Axis error and function block error share the same Error ID, but error

descriptions are different, as described in Table 7 on page 99

.

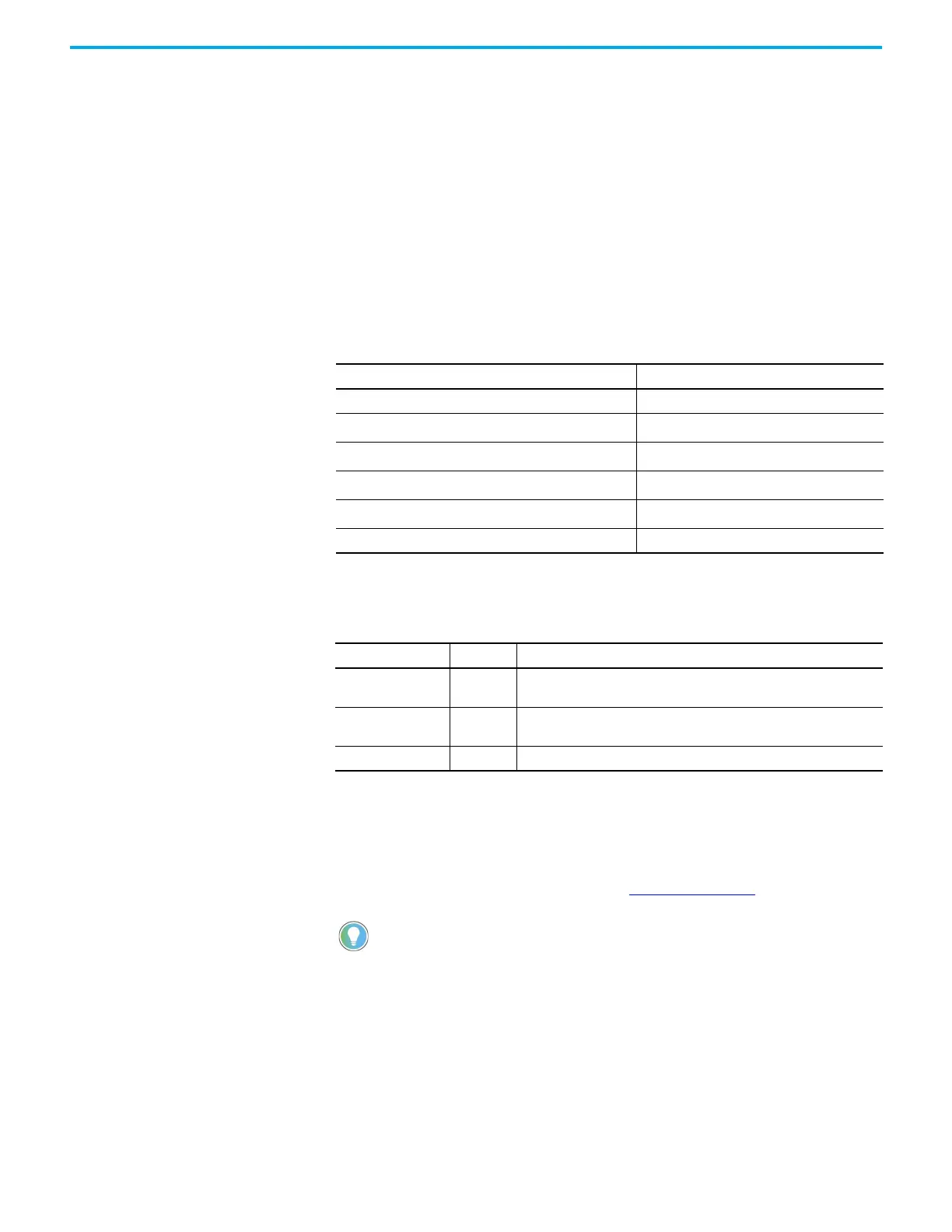

Data Elements for MC_Engine_Diag

Element Name Data Type

MCEngState UINT16

CurrScantime

(1)

(1) The time unit for this element is microsecond. This diagnostic information can be used to optimize motion configuration and user

application logic adjustment.

UINT16

MaxScantime

(1)

UINT16

CurrEngineInterval

(1)

UINT16

MaxEngineInterval

(1)

UINT16

ExtraData UINT16

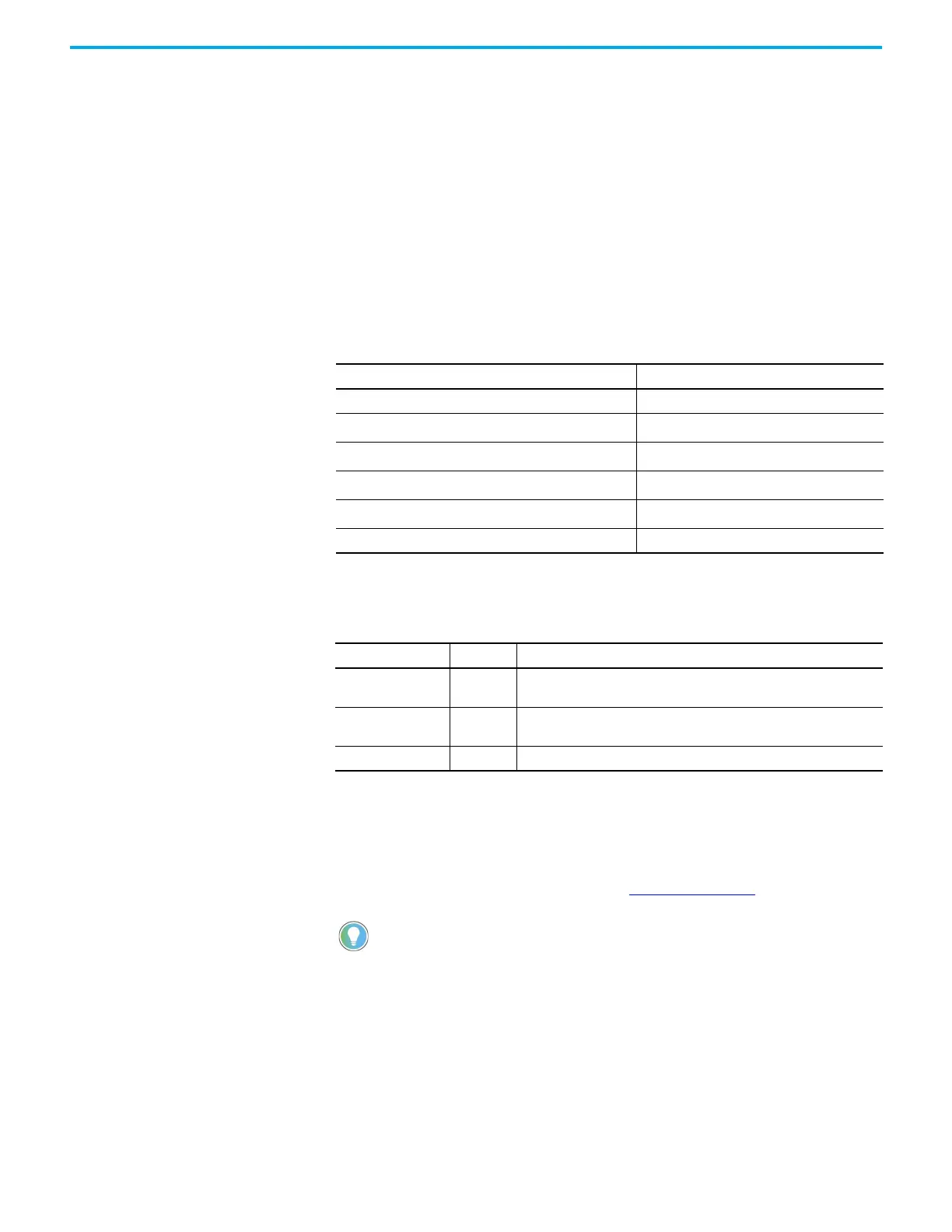

MCEngstate States

State Name State Description

MCEng_Idle 0x01

MC engine exists (at least one axis defined), but the engine is idle as there is no

axis is moving. The Engine diagnostic data is not being updated.

MCEng_Running 0x02

MC engine exists (at least one axis defined) and the engine is running. The

diagnostic data is being updated.

MCEng_Faulted 0x03 MC engine exists, but the engine is faulted.

Error code 128 is warning information to indicate the motion profile has been

changed and velocity has been adjusted to a lower value but the function

block can execute successfully.

Loading...

Loading...