Rockwell Automation Publication 2080-UM002L-EN-E - November 2021 277

Appendix F PID Function Blocks

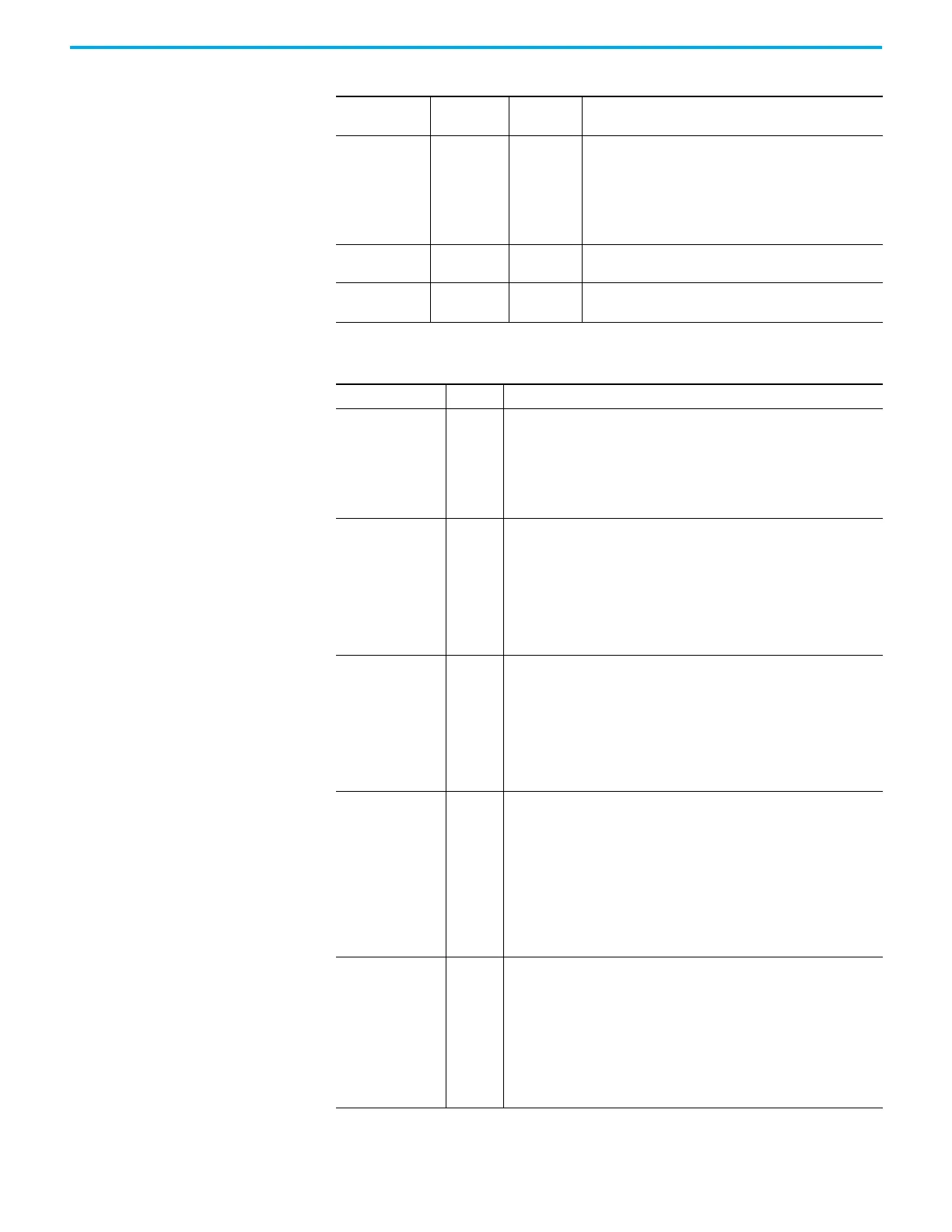

ATWarnings Output DINT

Warning for the AutoTune sequence. Possible values are:

0 = No auto tune done.

1 = In auto tune mode.

2 = Auto tune done.

-1 = Error 1: Input automatically set to TRUE, no auto tune

possible.

-2 = Error 2: Auto tune error, the ATDynamSet expired.

OutGains Output GAIN_PID

Gains calculated from AutoTune Sequences.

Use GAIN_PID data type to define the OutGains output.

ENO Output BOOL

Enable output.

Applicable to Ladder Diagram programs.

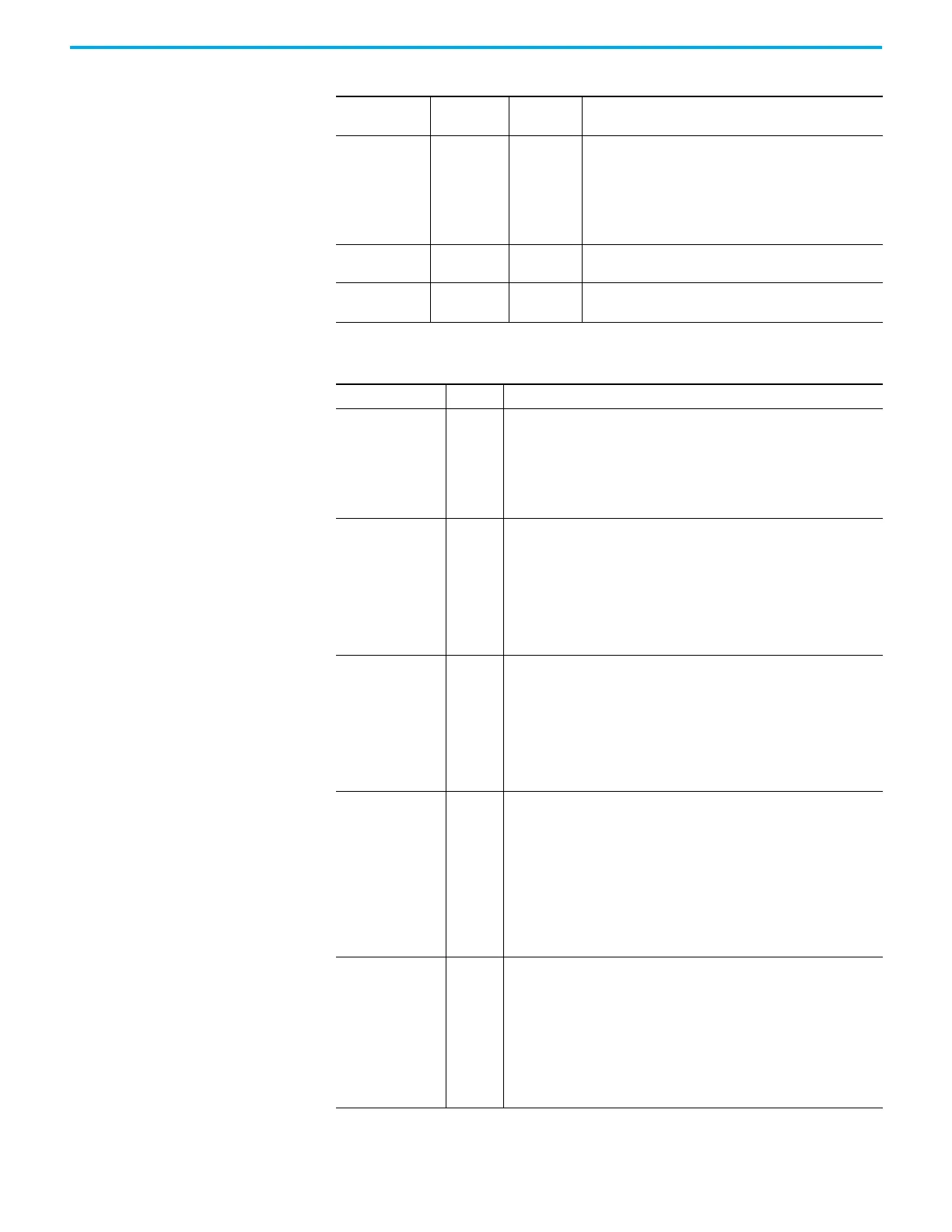

Table 62 - GAIN_PID Data Type

Parameter Type Description

DirectActing BOOL

Types of acting:

TRUE = Direct acting, output moves same direction as error. That is, the actual

process value is greater than the SetPoint and the appropriate controller action is

to increase the output. For example, Chilling.

FALSE = Reverse acting, output moves opposite direction as error. That is, the

actual process value is greater than the Setpoint and the appropriate controller

action is to decrease the output. For example, Heating.

ProportionalGain REAL

Proportional gain for PID (>= 0.0001).

Proportional gain for PID (P_Gain)

A higher proportional gain causes a larger change in the output based on the

difference between the PV (measured process value) and SV (set point value).

The higher the gain, the faster the error is decreased, but this may result in

instability such as oscillations. The lower the gain, the slower the error is

decreased, but the system is more stable and less sensitive to large errors. The

P_Gain usually is the most important gain to adjust and the first gain to adjust

while tuning.

TimeIntegral REAL

Time integral value for PID (>= 0.0001).

Time integral value for PID

A smaller integral time constant causes a faster change in the output based on

the difference between the PV (measured process value) and SV (set point value)

integrated over this time. A smaller integral time constant decreases the steady

state error (error when SV is not being changed) but increases the chances of

instability such as oscillations. A larger integral time constant slows down the

response of the system and make it more stable, but PV approaches the SV at a

slower rate.

TimeDerivative REAL

Time derivative value for PID (> 0.0).

Time derivative value for PID (Td)

A smaller derivative time constant causes a faster change in the output based on

the rate of change of the difference between PV (measured process value) and

SV (set point value). A smaller derivative time constant makes a system more

responsive to sudden changes in error (SV is changed) but increases the chances

of instability such as oscillations. A larger time constant makes a system less

responsive to sudden changes in error and the system is less susceptible to

noise and step changes in PV. TimeDerivative (Td) is related to the derivative gain

but allows the derivative contribution to PID to be tuned using time so the sample

time must be taken into consideration.

DerivativeGain REAL

Derivative gain for PID (>= 0.0).

Derivative gain for PID (D_Gain)

A higher derivative gain causes a larger change in the output based on the rate of

change of the difference between the PV (measured process value) and SV (set

point value). A higher gain makes a system more responsive to sudden changes

in error but increases the chances of instability such as oscillations. A lower gain

makes a system less responsive to sudden changes in error and makes the

system less susceptible to noise and step changes in the PV.

If derivative gain is set to zero, it disables the derivative portion of the

PID.

Table 61 - IPIDCONTROLLER Arguments (Continued)

Parameter

Parameter

Type

Data Type Description

Loading...

Loading...