48 Rockwell Automation Publication 20D-PM001D-EN-P - March 2019

Chapter 2 Programming and Parameters

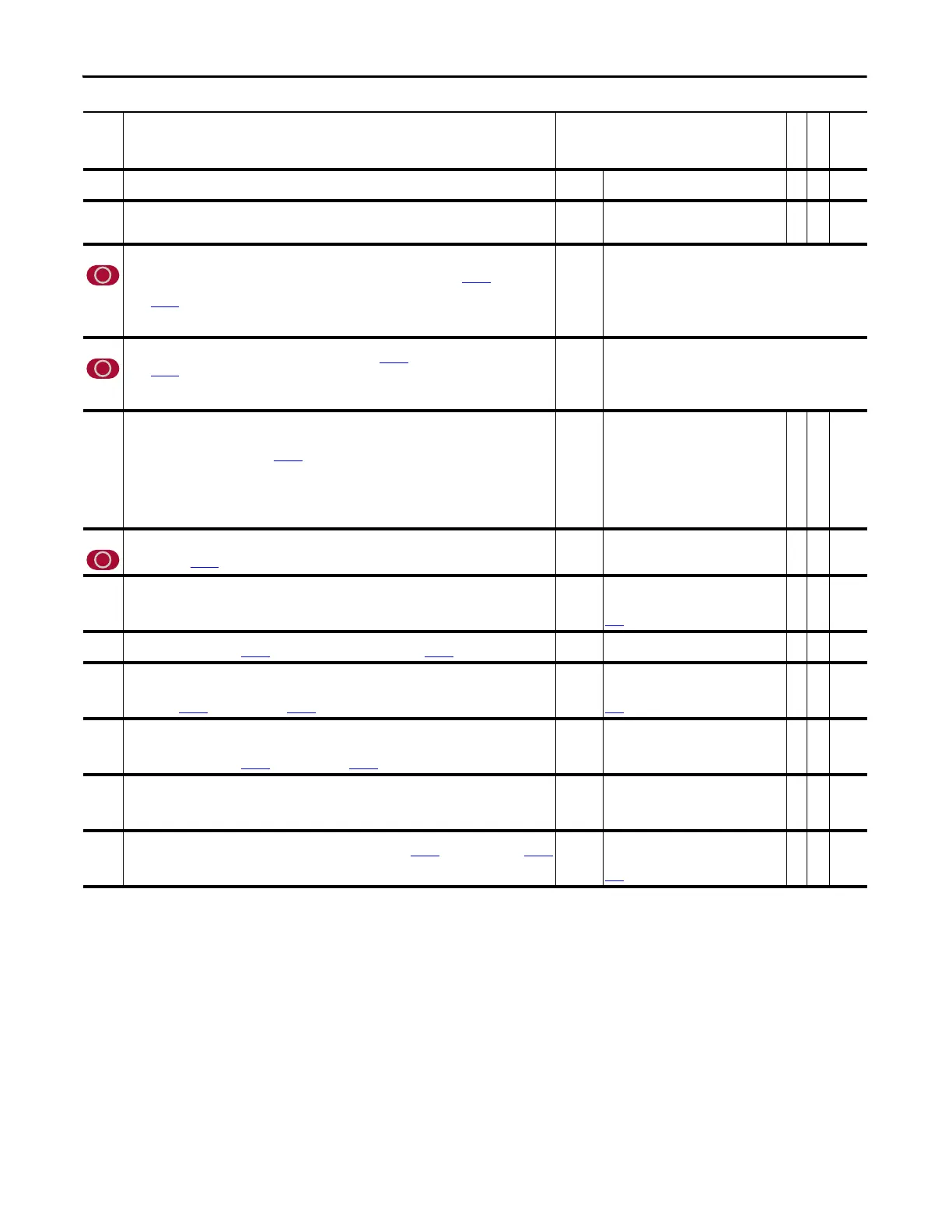

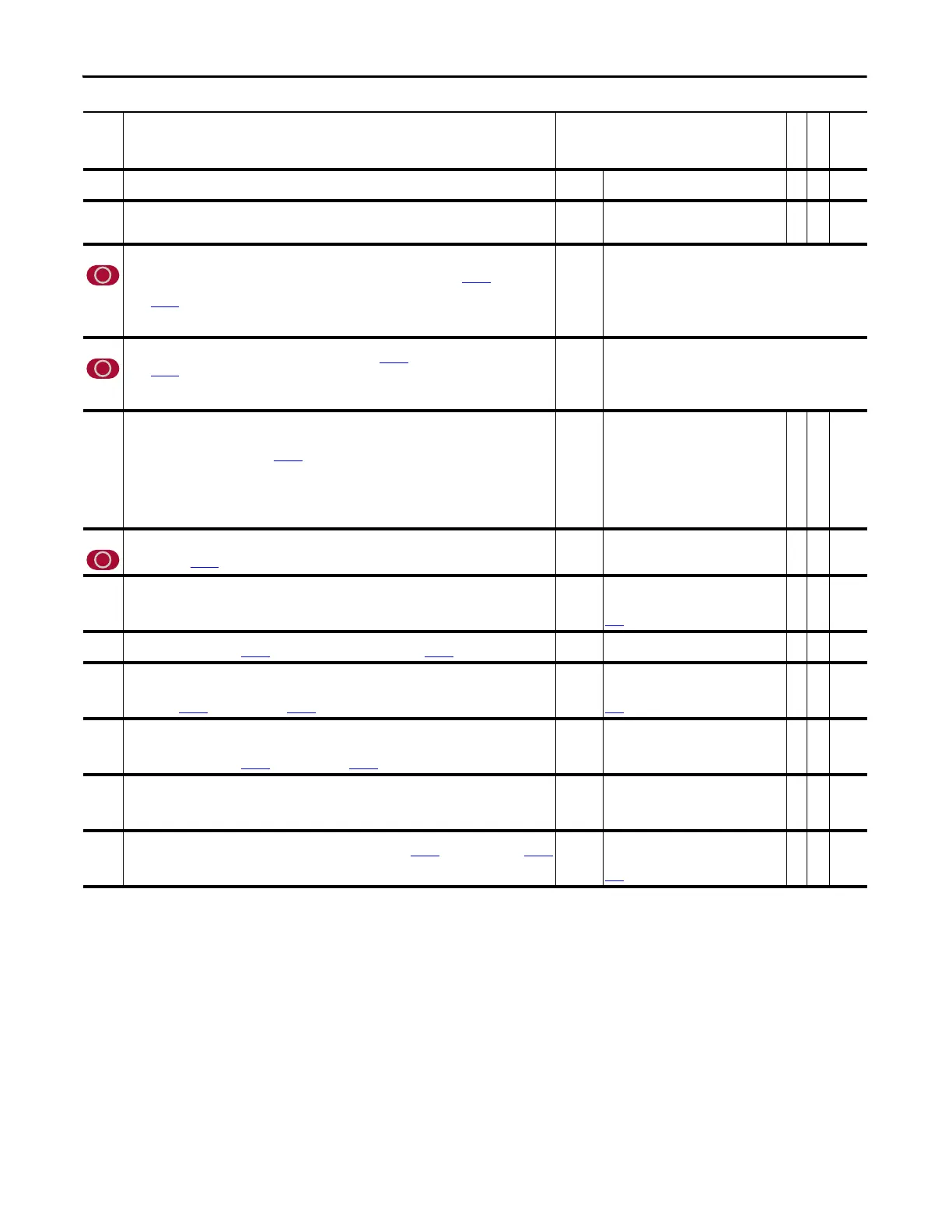

219 PeakDetect2 Out

Output from the second peak/level detector.

Default:

Min/Max:

0.00

0.00/1200.00

RO Real

221 Load Estimate

Displays the estimated load torque, which is the side effect of the speed observer and does not include torque to

accelerate or decelerate the motor if the inertia input is correct. The value is provided for display purposes.

Default:

Min/Max:

Units:

0.0

-/+8.0 P.U.

P. U .

RO Real

222 Mtr Fdbk Sel Pri

Selects primary feedback device. The primary feedback device configuration must not be set to fault on an event

in order to allow operational feedback switch over to the alternate feedback device set in Par

223 [Mtr Fdbk Sel

Alt].

Notes: Par 485 [Motor Ctrl Mode] must be set to FOC for Sensorless feedback selection to be active. Selection 5 is

only available when compatible feedback option card is installed. This parameter was changed to non-linkable for

firmware version 3.001.

Default:

Options:

0 =

0 =

1 =

2 =

3 =

“Encoder 0”

“Encoder 0” 4 = “Motor Sim”

“Encoder 1” 5 = “FB Opt Port0”

“Sensorless”

“Reserved”

223 Mtr Fdbk Sel Alt

Selects alternate feedback device if the feedback device selected in Par 222 [Mtr Fdbk Sel Pri] fails.

Notes: Par

485 [Motor Ctrl Mode] must be set to FOC for Sensorless feedback selection to be active. Selection 5 is

only available when compatible feedback option card is installed. This parameter was changed to non-linkable for

firmware version 3.001.

Default:

Options:

2 =

0 =

1 =

2 =

3 =

“Sensorless”

“Encoder 0” 4 = “Motor Sim”

“Encoder 1” 5 = “FB Opt Port0”

“Sensorless”

“Reserved”

224 TachSwitch Level

Sets the detection level for the automatic tach loss switch-over routine. A drop in feedback speed at this percent of

rated speed over 0.5 msec will cause a tach switch from primary to alternate feedback device. This feature is

enabled when bit 16 “Auto Tach Sw” in Par 153 [Control Options] is selected.

Setting this level lower will make the tach switch detection more sensitive and lower the minimum speed at

which a tach switch can occur. Setting this level higher will make the tach switch less sensitive and raise the

minimum speed for tach switch detection.

Note: This parameter was changed to non-linkable for firmware version 3.001.

Default:

Min/Max:

Units:

10.0000

5.0000/25.0000

%

RW Real

225 Virtual Edge/Rev

Set the edges per revolution (EPR) scaling for calculating motor position. Used in the calculation of the position

feedback such as Par 229 [MtrPosit Stimulat].

Default:

Min/Max:

Units:

4096

10/16777216

EPR

RW 32-bit

Integer

226 Motor Speed Est

Displays the estimated motor speed, calculated when the selected feedback is sensorless or when encoderless

ridethrough is enabled.

Default:

Min/Max:

Units:

Scale:

0.0000

-/+14112.0000

rpm

Par

4 [Motor NP RPM] = 1.0 P.U.

RO Real

227 Motor Posit Est

Summation (or integration) of Par 226 [Motor Speed Est] scaled by the value in Par 225 [Virtual Edge/Rev].

Default:

Min/Max:

0

-/+2147483648

RO 32-bit

Integer

228 MtrSpd Simulated

The motor speed output of the motor simulator. The motor simulator provides motor speed information during

setup and troubleshooting when actual motor control is not desired or possible. To use the motor simulator, enter

a value of 4 in Par 222 [Mtr Fdbk Sel Pri] or Par 223 [Mtr Fdbk Sel Alt].

Default:

Min/Max:

Units:

Scale:

0.0000

-/+14112.0000

rpm

Par 4 [Motor NP RPM] = 1.0 P.U.

RO Real

229 MtrPosit Simulat

The motor position output of the motor simulator. The motor simulator provides motor position information

during setup and troubleshooting when actual motor control is not desired or possible. To use the motor

simulator, enter a value of 4 in Par

222 [Mtr Fdbk Sel Pri] or Par 223 [Mtr Fdbk Sel Alt].

Default:

Min/Max:

0

-/+2147483648

RO 32-bit

Integer

230 Encdr0 Position

Displays the position feedback (accumulator) from encoder 0. The value changes by a value of four times (4x) the

Pulses Per Revolution (PPR) rating of the encoder for each full revolution of the encoder shaft. Used by the Velocity

Position Loop (VPL) to close the position loop if position control is selected.

Default:

Min/Max:

0

-/+2147483648

RO 32-bit

Integer

231 Encdr0 Spd Fdbk

Displays the speed feedback from encoder 0. Calculated from the change of Par 230 [Encdr0 Position] and Par 232

[Encoder0 PPR].

Default:

Min/Max:

Units:

Scale:

0.0000

-/+14112.0000

rpm

Par

4 [Motor NP RPM] = 1.0 P.U.

RO Real

No. Name

Description

Values

Linkable

Read-Write

Data Type

Loading...

Loading...