22

9

10

CA

E

B

B

F

D

G

H

K

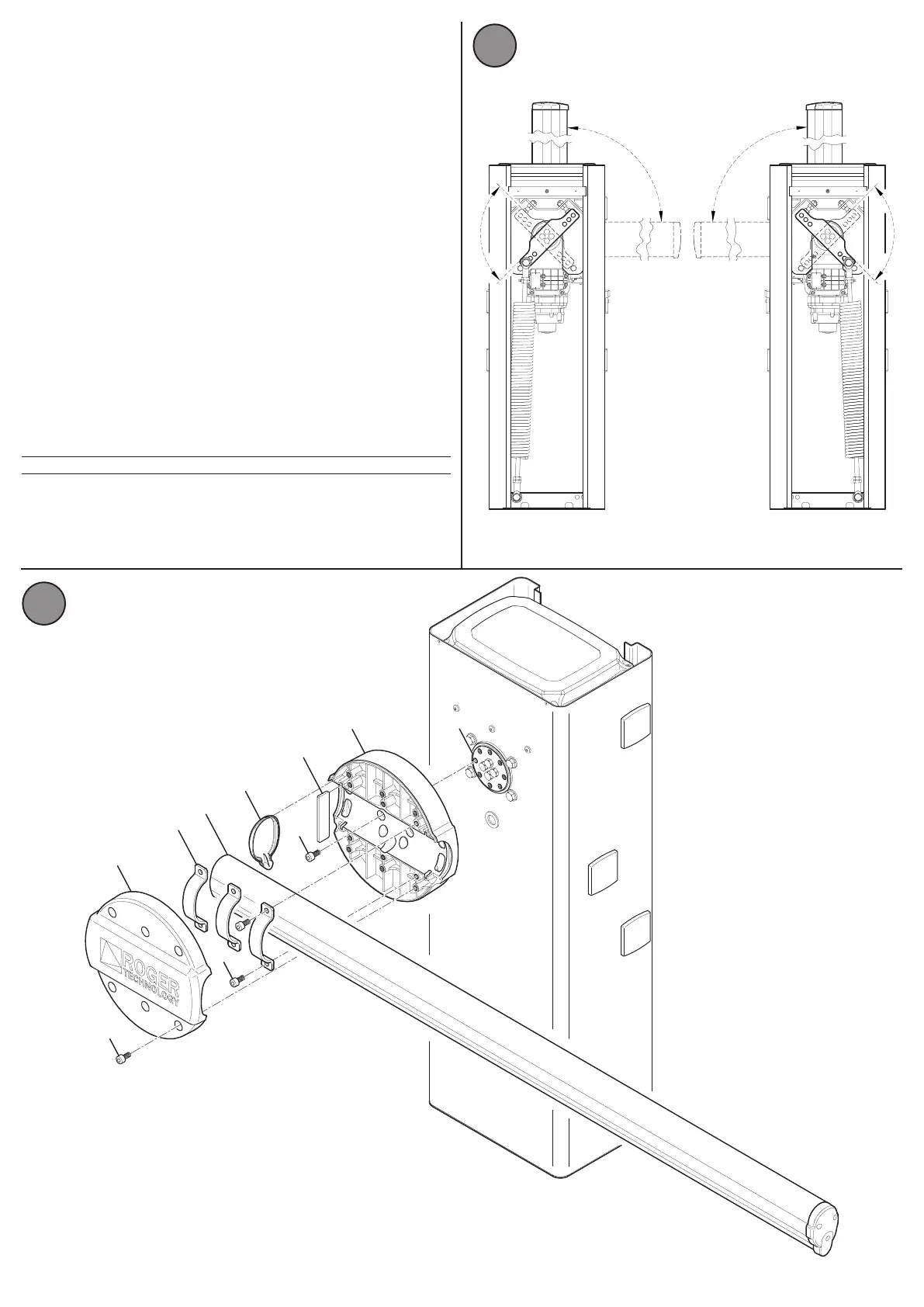

7.3) Installaon of the bar

Before installing the bar, ensure that the internal arm for securing the spring is

oriented in the correct direcon, according to the arrangement of the barrier

of a right or le installaon, as shown in

Fig 9.

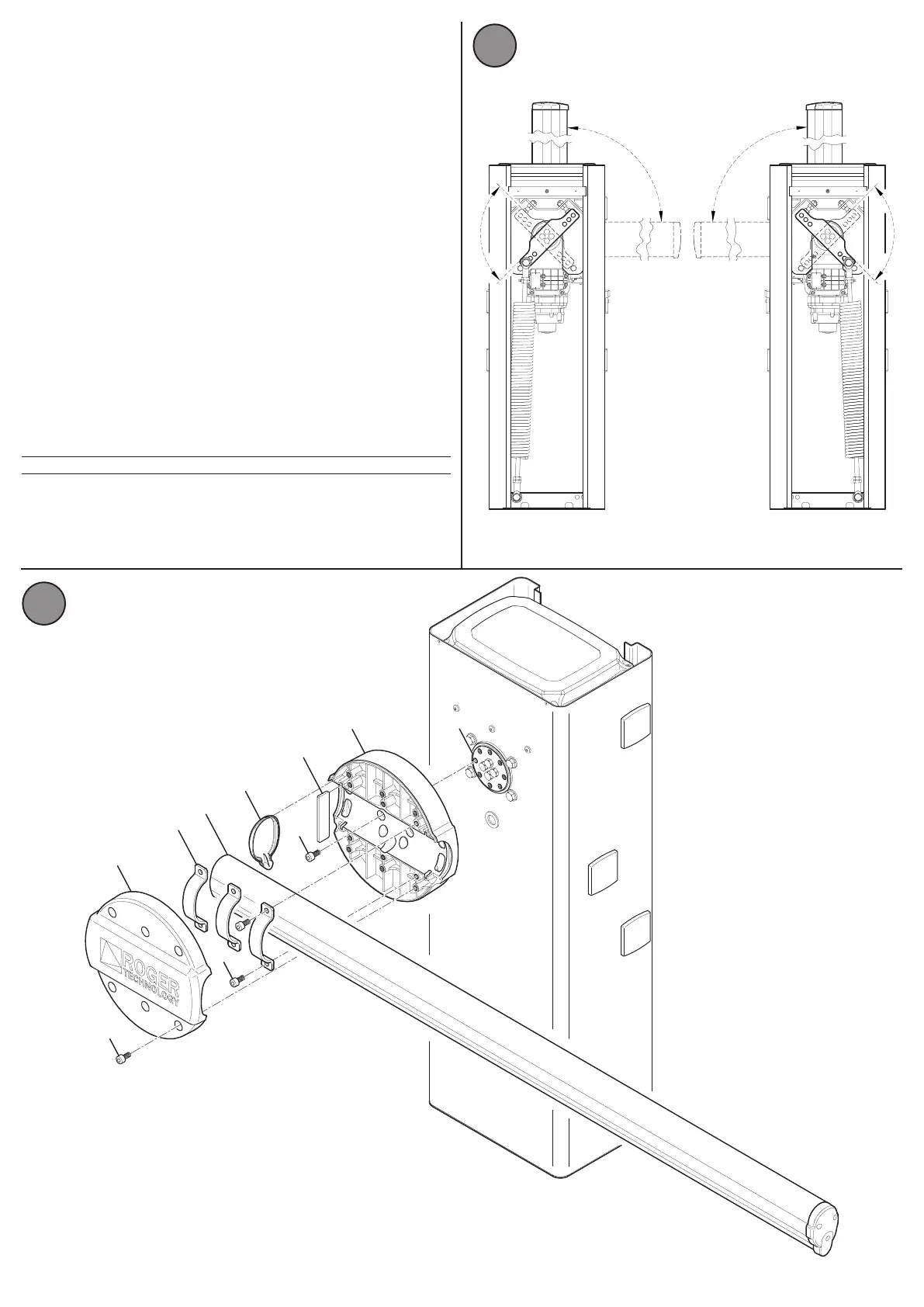

To install a bar, proceed as described:

Release the geared motor through the appropriate release key supplied

with the barrier (see Chapter 10); manually rotate the arm unl it reaches

the proper recommended posion, which provides for the ability to vercally

insert the bar, using a removable iron support such as a bar support point,

when inserted

(Ref. "E" Fig. 10). Tighten the geared motor again by turning the key in the

opposite direcon and proceed with the assembly of the bar as shown in Fig 10:

Secure the aluminium bar support base (A)

with 8 galvanized M10 screws

(B)

to the xing ange that comes out of the geared motor (C). Tighten with

adequate strength.

Rest the bar (D)

in its slot and push it in support to the steel plate (E);

apply the

three moulded steel anges (G)

and secure with 6 galvanized M10 screws (B).

Tighten with adequate strength. Posion the plasc end cap in its slot (F). Now

apply the nal aluminium cover (H)

and secure it with 6 steel M10 screws (K).

If necessary, reverse the orientaon as follows:

Release the geared motor (see Chapter 10); manually rotate the arm unl it

reaches the proper posion. Tighten the geared motor by turning the key in

the opposite direcon.

Now remove the cover of (H), loosen the xing ange unl the bar slides freely,

(G), remove the plasc end cap (F) and slide the bar up to the desired posion.

Posion the plasc cap and reaach all previously removed or loosened parts.

Note: For correct conguraon of the le/right opening of the automac

barrier, refer to the of the control unit manual AG / CTRL parameter No. 71.

Loading...

Loading...