23

123

ABC

11

12

13

14

15

A A

B

B

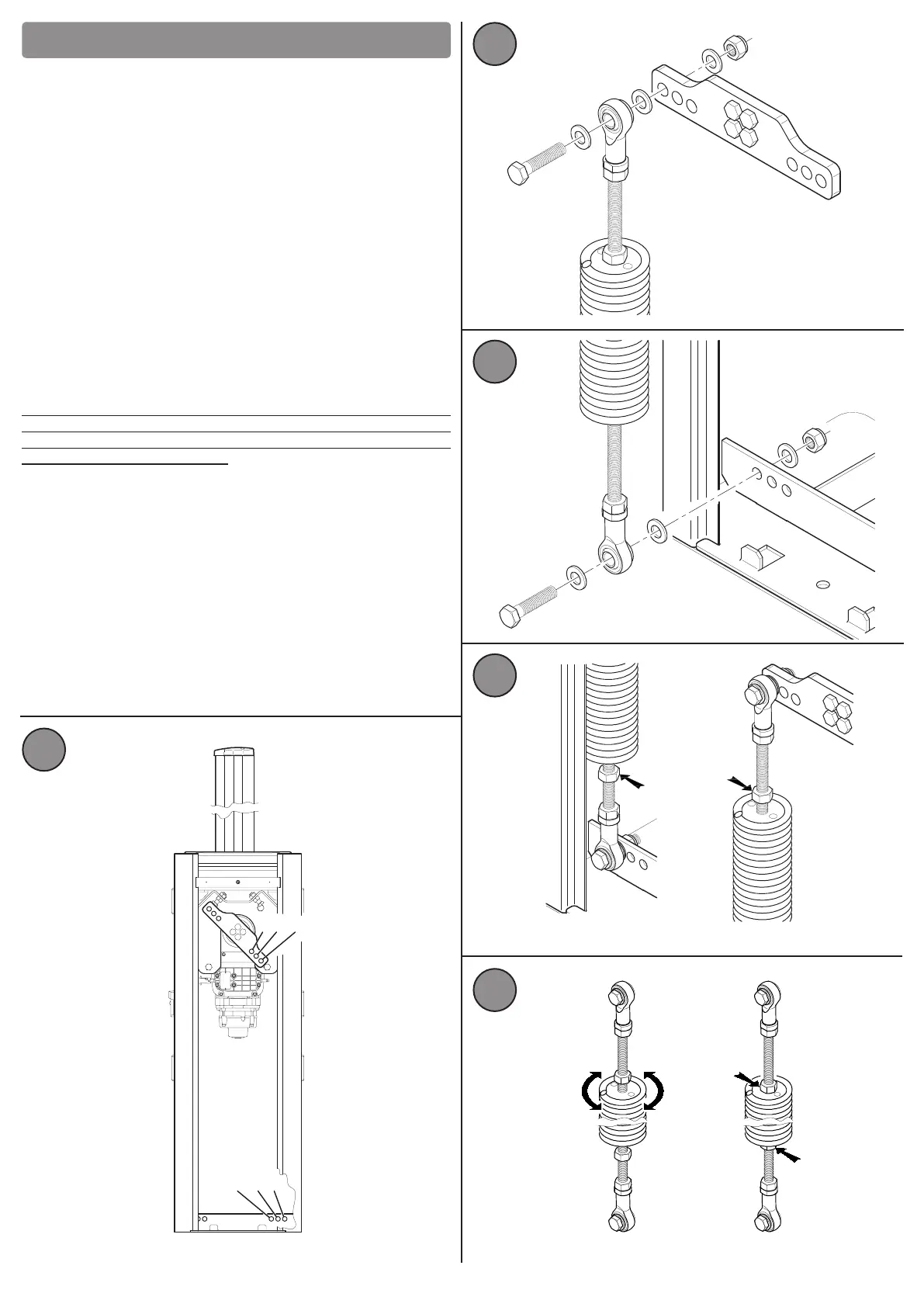

8 BAR BALANCING SPRING

8.1) Installaon and balancing of the spring of the bar

To balance the forces in play and for proper operaon of the automac

barrier, it is necessary to install a balancing spring.

Depending on the length of the bar that you intend to install, choose

between two dierent models of the following springs:

AG/SP/72: Spring for bars of up to 4 metres.

AG/SP/83: Spring for bars up to 6 metres in either a single bar or 2 joined

bars.

To assemble the spring, choose a pair of holes from the steel supports

highlighted in Fig 11 (e.g. A-1, A-2 or B-2 etc.), paying aenon to assemble

the spring on the right side, based on the posion of the bar. Warning: using

holes posioned closer or further away from the centre of the arm aects

the tension of the spring, for example, if you use hole No. 3, the spring is

more stretched.

Secure the spring by screwing it into steel arm, in the arranged holes, using

the supplied screws, following the diagram in Fig. 12.

Secure the spring to the xed structure, on the steel beam at the base of

the column of the barrier using the supplied screws, following the diagram

in Fig. 13.

Note that both springs are indicated with a red or yellow colour in the

respecve hubs, according to the diameter type of the spring. So pay

aenon during the installaon, ensuring that the coloured part of the

spring is always posioned upward.

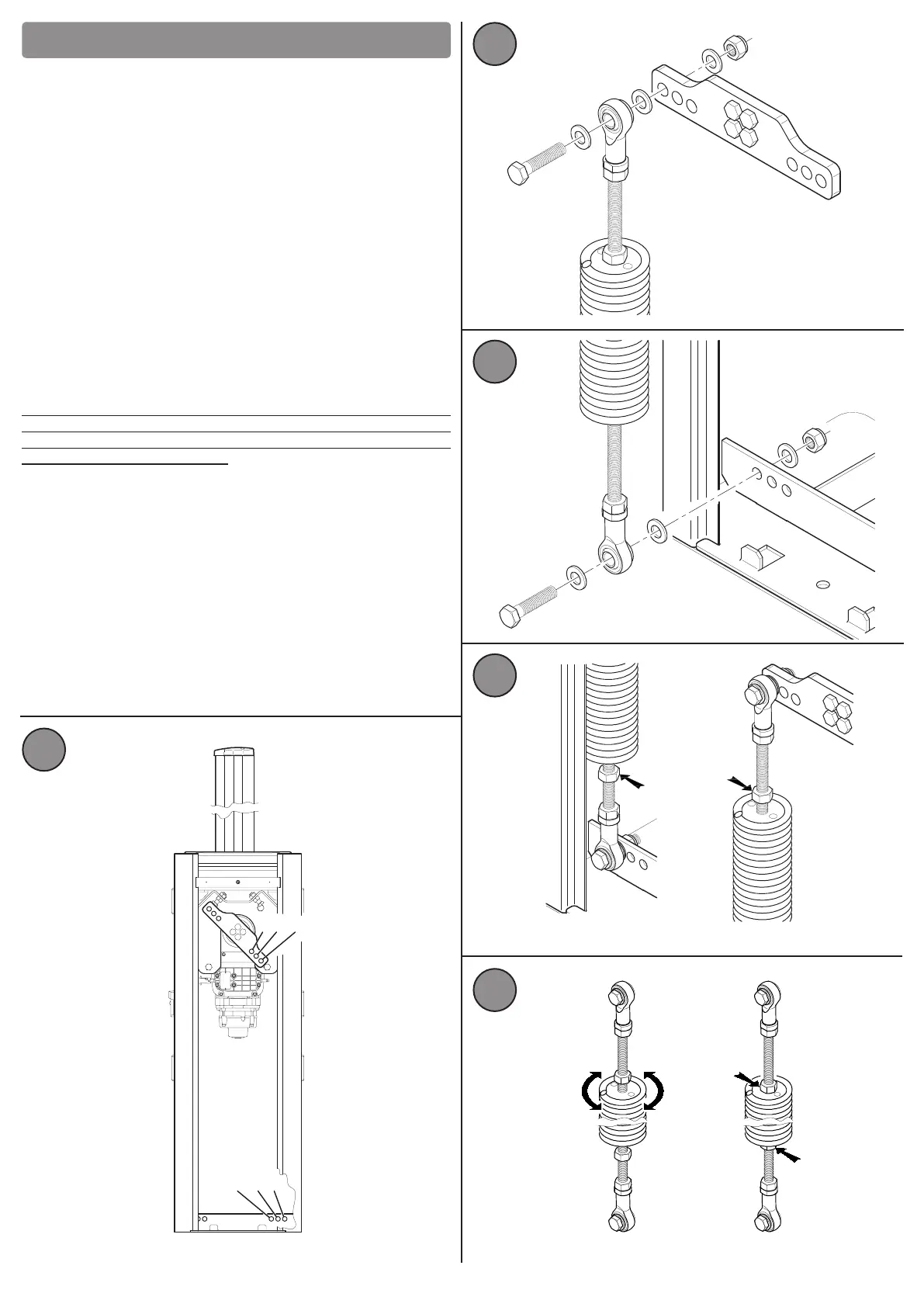

8.2) Adjusng the spring tension

When the automaon is released (see Chapter 10), manually move the bar

by 45° and release it. If it opens or closes, it means that the balance is not

opmally set. This depends on the length of the bar and the accessories

installed in it and therefore on its own weight.

For opmum results, it is necessary to adjust the tension of the previously

installed spring, inially by unscrewing the lock nuts of the spring, shown

in Fig. 14, both the one above and the one below and manually rotate the

spring (Fig. 15 A) in a clockwise or anclockwise direcon to decrease or

increase the tension; when the adjustment of the tension of the spring is

opmal, it is necessary to rmly ghten the locking nuts of the spring (Fig.

15 B).

Loading...

Loading...