24

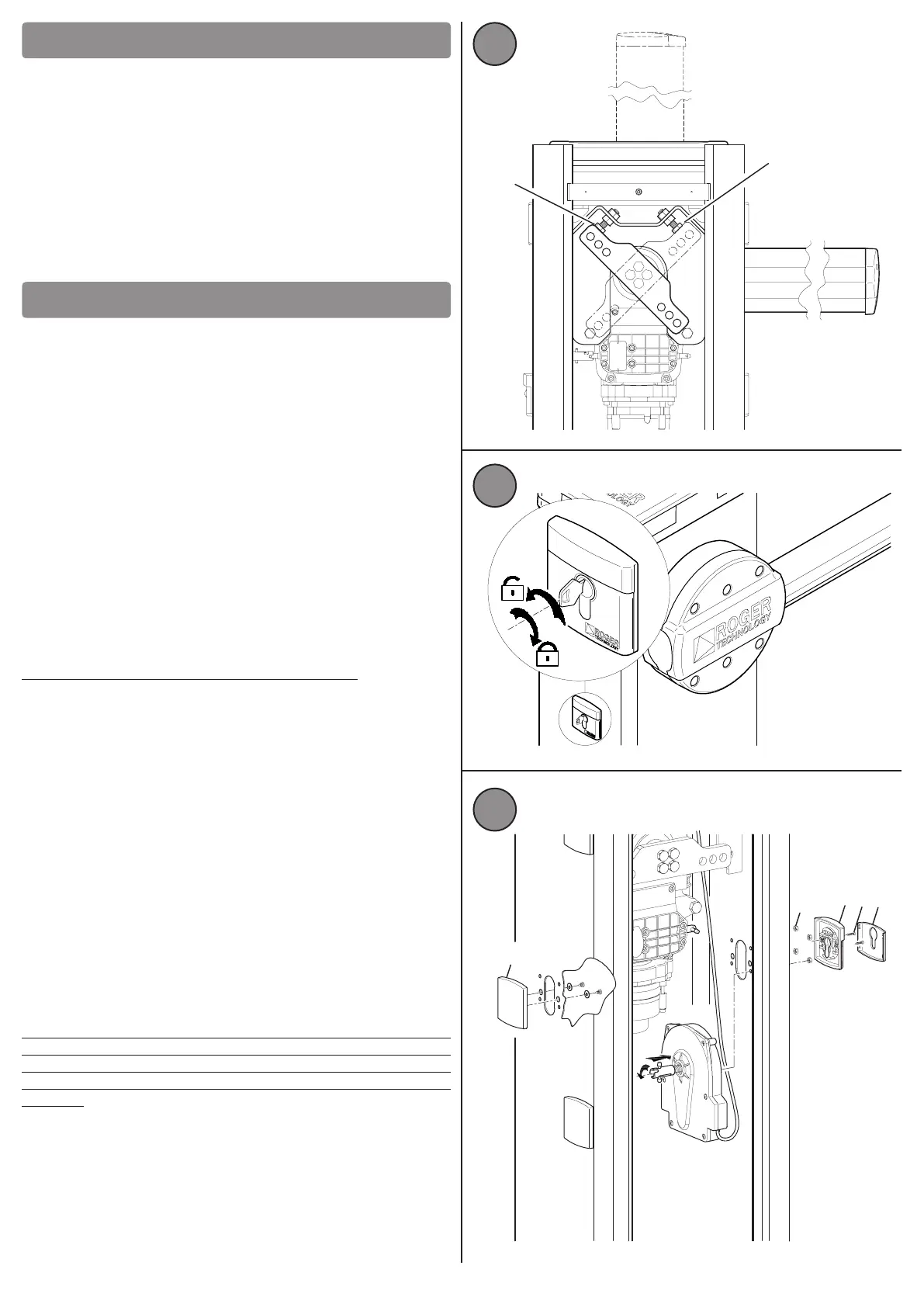

9 ADJUSTING THE MECHANICAL STOP IN OPENING AND CLOSING

The automaon is provided with mechanical stops in opening and closing

which must be adjusted with precision, following the procedure indicated

below.

Warning: Fig. 16 shows the installaon of a LEFT automaon; in the event of

a RIGHT installaon, it is necessary to adjust in a specular fashion.

Unlock the automasm with the supplied key (see Chapter No. 10).

Adjust the screws of the mechanical stop in closing (Fig. 16 point A) to

horizontally adjust the bar in a closed posion. Adjust the screws of the

mechanical stop in opening (Fig. 16 point B) to vercally adjust the bar in

an open posion.

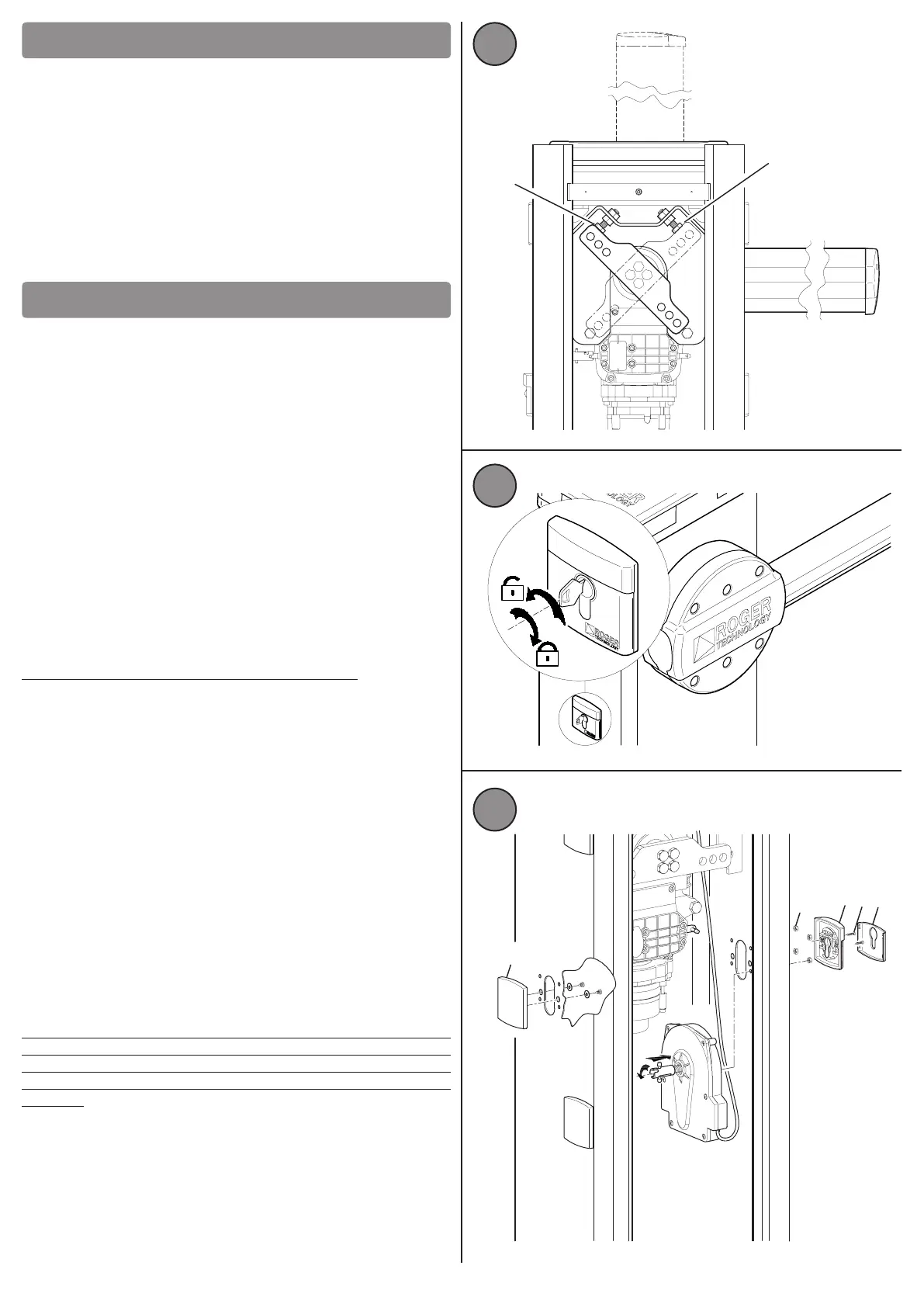

10 AUTOMATISM RELEASE

In some situaons, such as in the event of a power outage or scheduled or

extraordinary maintenance, it is necessary to release the automaon.

The operaon of the release of the automaon must never be carried out

when the bar is in moon and it is therefore necessary to ensure that the bar

is stopped and in the closed posion (horizontal).

Moreover, ensure that at the me of release, no person, animal, item or

vehicle is passing by or stopped within range of automaon.

To release it, it is necessary to insert the release key supplied on the lock,

which is located on a side of the case (Fig. 17), and make 2 complete turns

anclockwise (2 x 360°).

To lock the automasm again, it is necessary to turn the key clockwise and

make 2 full turns (2 x 360°).

In the case of incorrect installaon or improper securing of the bar in its slot

during assembly, or in the case of a bar that has been broken by an accident

or another cause, the springs installed under tension no longer guarantee

the balancing set. Pay aenon as this situaon can cause sudden rotaon

of the bar, during the release operaon, and therefore pose a potenal

hazard to the user.

10.1) Assembly of the release system on the opposite side

The release system is assembled in the factory on one of the two sides of the

case. It is possible to disassemble and reassemble it on the opposite side, by

following the procedure shown in Fig 18:

Open the inspecon door of the automaon case.

Unscrew the xing screws of the plasc cover (A) on the side on which you

want to install the release.

Remove the plasc cover plate (B) of the release system, by leveraging the

four side latches; unscrew the two self-tapping screws (C) and remove the

aluminium front (D); remove the four M5 nuts (E).

Now the release system is no longer secured to the automation structure

and so release is possible, by pushing the steel joint outwards (F) by

compressing the spring, and then rotating the same joint by 45° (G), finding

the self-retaining point.

In order to assist and to check the correct assembly of the release, on the

opposite side two RED and GREEN caps have been included in the rotaon

plugs.

Note: To check the correct assembly of the release independently of the

side, check that the two green plugs are facing the operator's side if the

barrier is blocked. In the case where the green caps are facing the opposite

side of the operator, this means that the release has been assembled

otherwise.

Then, remove the release box and assemble it on the opposite side, paying

aenon to the safety wiring.

For the nal xing, follow the instrucons in reverse. Lastly, complete the

task by xing the plasc cover (A) on the side where the release was inially

assembled.

A

B

16

2 x 360°

2 x 360°

17

18

A

B

C

D

E

F

G

Loading...

Loading...