RB48 BROOM

4.3ROSCO - A LeeBoy Company

Maintenance

MAINTENANCE

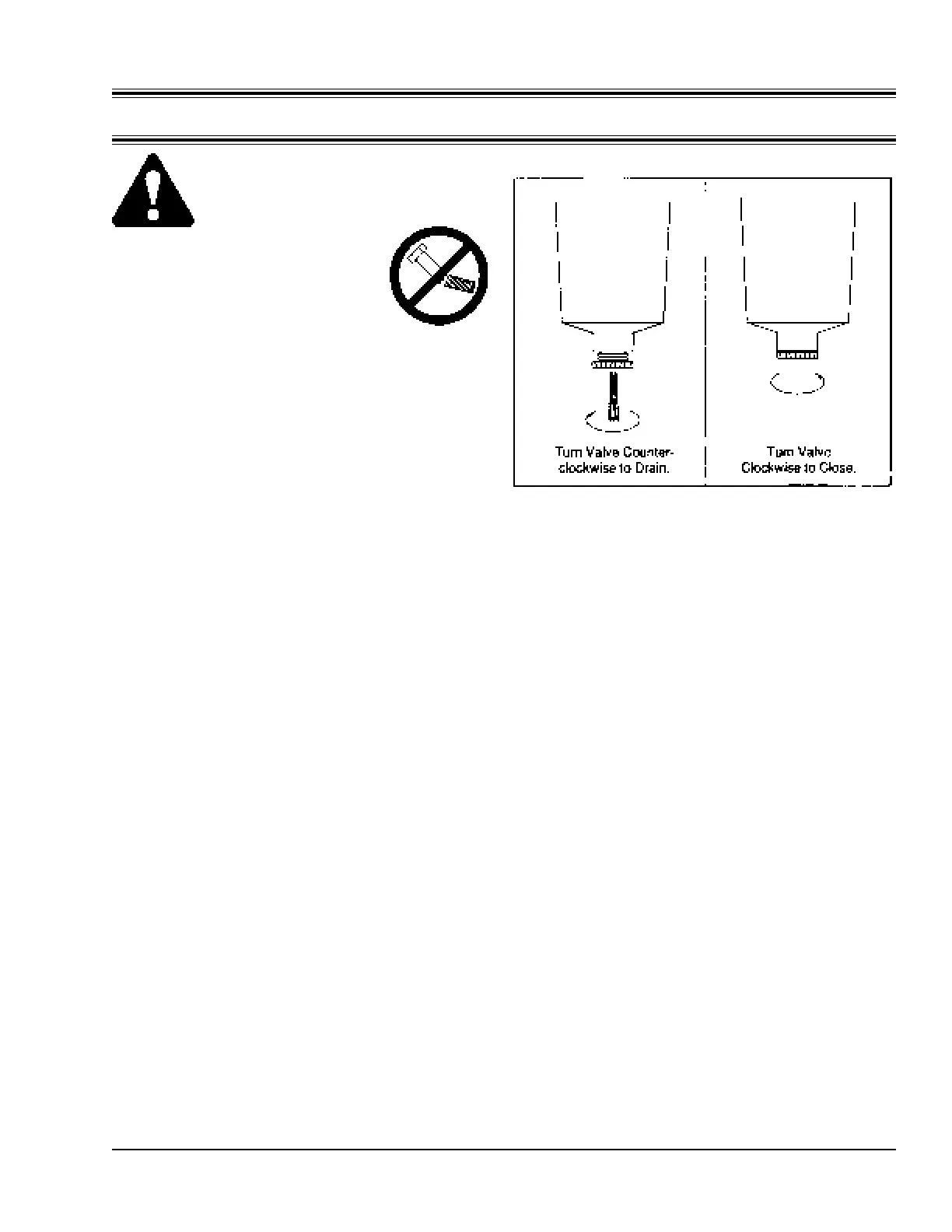

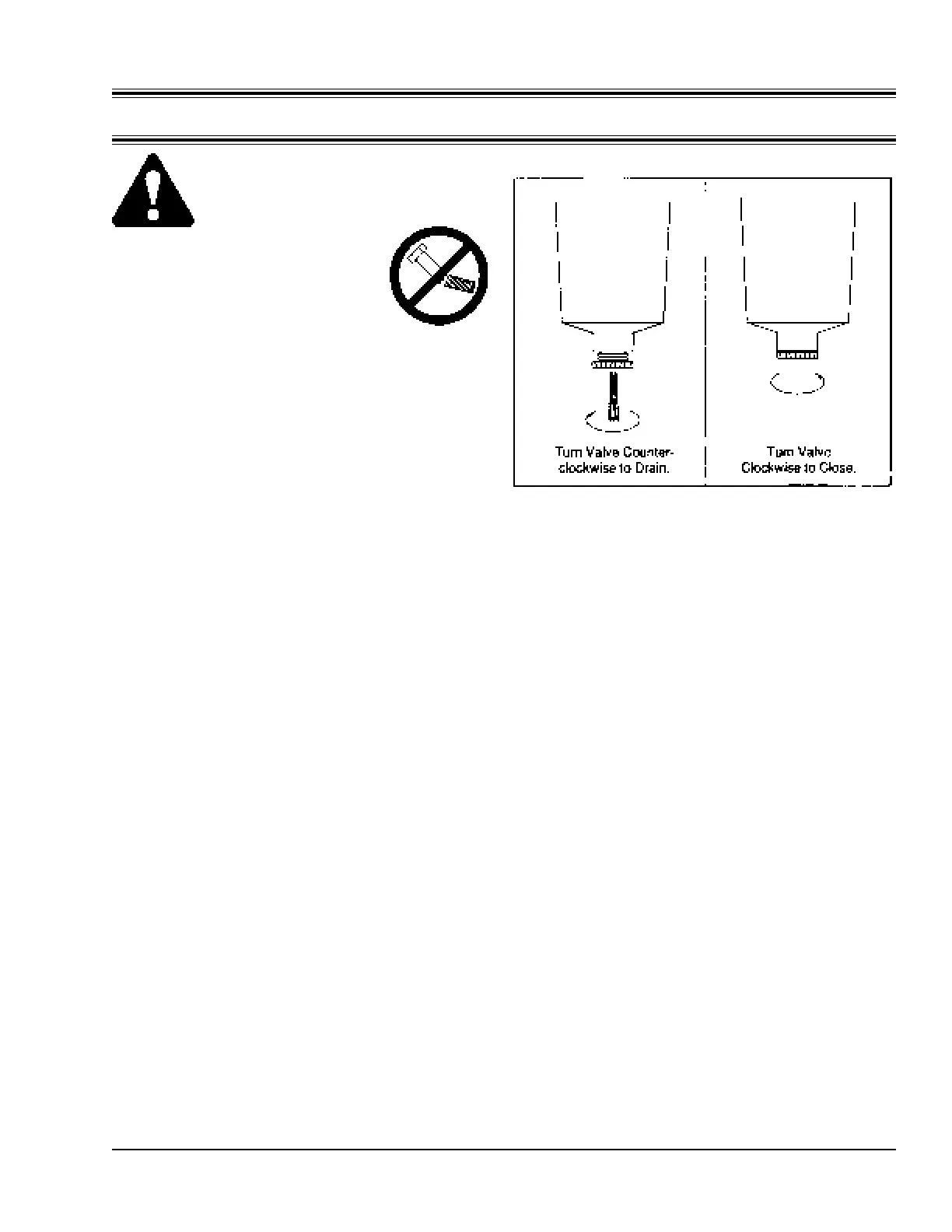

Figure 4-A

Engine Water Separator

WARNING: Do not inhale ether

fumes. They are extremely harmful.

Do not spray excessive amounts

(two seconds per time) of ether

starting fluid when starting the

engine. Using too much ether will

cause engine damage.

If the unit is equipped with an Automatic Ether

Injection System, use the following described

steps for starting in cold weather.

A. Put unit in neutral and set parking brake.

B. Set throttle to idle.

C. While cranking the engine, inject a metered

amount of ether starting fluid by pushing the Ether

Injection button.

D. Be sure the engine oil pressure is indicated

on the gauge within 30 seconds after starting.

E. Never inject ether for more than two (2)

seconds at a time.

Fuel Filter and Water Separator

Diesel engine injection systems use fuel for

lubrication of close tolerance internal engine parts.

Proper maintenance of the fuel filters and the fuel

tank are required for continued top performance

and to prevent damage to internal engine

components.

The engine fuel filter and water separator are

located on the left side of the engine. A drain

valve is provided on the bottom of the water

separator (Figure 4-A).

A. Before operating the engine, use the valve

to drain a small quantity of fuel from the water

separator into a clean, clear container. This is an

absolutely necessary daily routine.

B. If water or contaminants are found in the

fuel you drained, DO NOT attempt to start the

engine. Continue to drain fuel into the container

until it runs clear.

C. If large amounts of contamination are

found, drain the fuel tank until the lines run clear.

Replace the filters. Fill new filters with fresh clean

fuel and install.

The manufacturer's diesel engine manual provided

with your broom contains more detailed

information on fuel system maintenance

procedures.

Crankcase Oil

A. Engine crankcase oil level should be

checked daily prior to each day's use of the

broom. The machine must be parked on a level

surface when checking the oil to assure accurate

measurements. When checking oil while the

engine is warm, wait until the engine has been

OFF for at least five minutes. This allows oil to

drain back to the crankcase.

Loading...

Loading...