RB48 BROOM

4.9ROSCO - A LeeBoy Company

Maintenance

MAINTENANCE

3. If this technique isolates the leak, replace

the defective hose assembly or fitting. Never

attempt to repair hydraulic hoses and/or leave

tape attached.

C. An operator should inspect the broom

during operation for hydraulic leaks which may

only be noticeable while the unit is running.

Pumps and Motors

The hydraulic pump and motor generally require

no regularly scheduled maintenance. As stated

above, frequent inspection for leaks will indicate

the need for service of these components.

A. Adjusting Priority Relief Valve - The

Priority Circuit on the hydraulic pump supplies the

power steering with approximately 4 GPM of

hydraulic flow. This flow goes to the steering

circuit before any other circuit. Occasionally, it

may be necessary to readjust the Relief Valve

setting. The Priority Relief Valve controls the

maximum operating pressure for the power

steering and brush lift and swing circuits. The

Relief Valve is located in the hydraulic pump

attached to the rear of the hydrostatic pump on the

engine flywheel housing. The following are signs

that the Priority Relief Valve needs adjusting:

- Total or partial loss of steering functions or

hard steering

- Constant noise from hydraulic pump when

using steering or brush lift and swing

- Hydraulic oil overheating

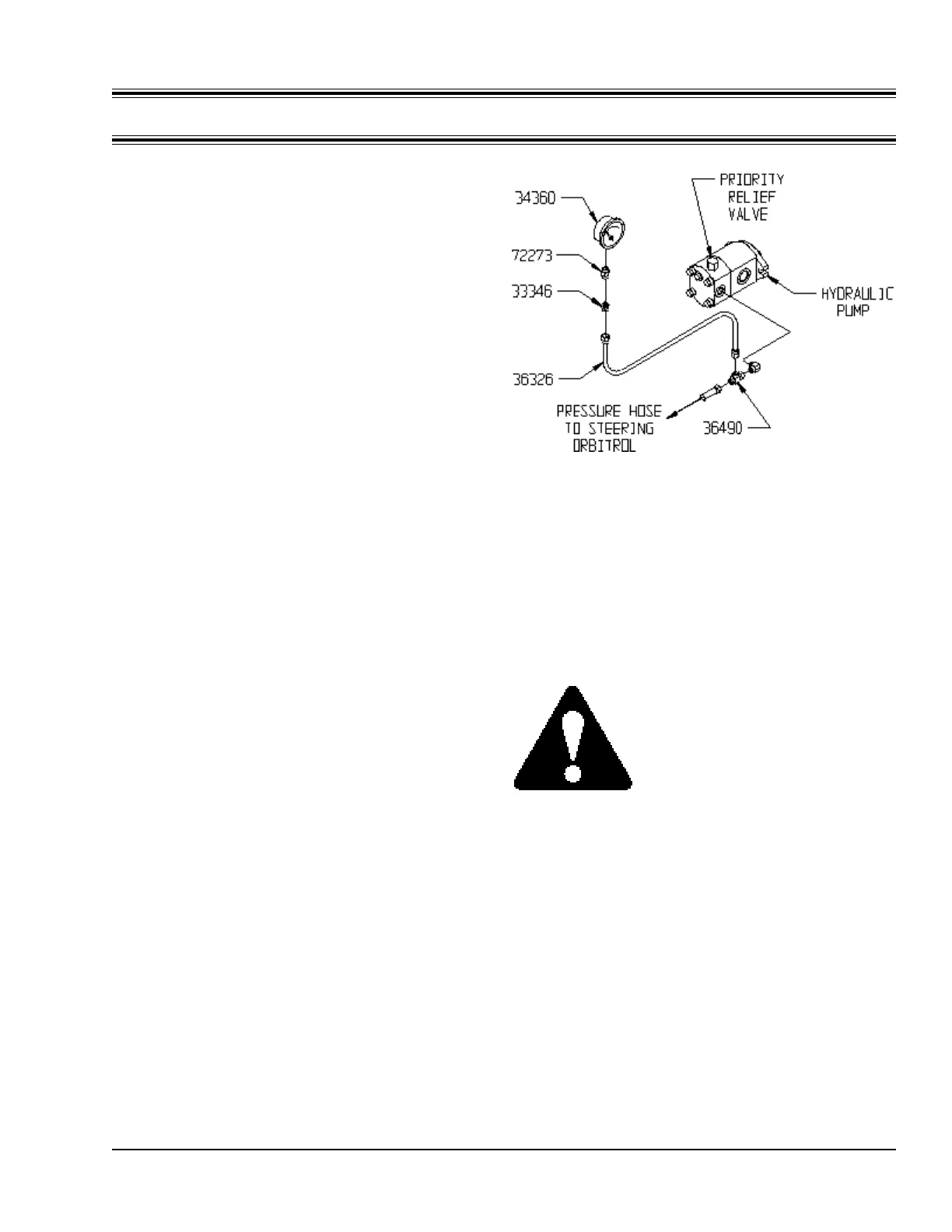

1. Plumb in a 0 to 5000 psi pressure gauge

into the Priority Flow Circuit as shown in

Figure 4-D. Parts needed for this, including

a pressure gauge, can be obtained from

your authorized Rosco dealer. Part

numbers are listed in Figure 4-D.

2. Start the engine and warm the hydraulic oil

to at least 100° F.

Figure 4-D

Setting Priority Relief Valve

3. Set the parking brake and be sure the

transmission is in neutral. Use the foot

brake as an extra precaution.

CAUTION: Use extreme

caution when working under the

ROSCO Broom while adjusting

priority relief pressure. Have

another person who is familiar

with the machine assist you.

4. Increase engine speed to 2500 RPM.

5. Raise the brush using the lift circuit until it

stops. Continue to hold pressure to lift

cylinder until a gauge reading can be

taken.

6. The pressure gauge should read 1500 +/-

50 psi.

7. Adjust relief pressure by removing the

locknut and turning the adjusting screw

clockwise to increase pressure and

counterclockwise to decrease pressure.

Loading...

Loading...