RB48 BROOM

4.17ROSCO - A LeeBoy Company

Maintenance

HYDRAULIC FLUIDS

The below recommended hydraulic oils have been

reviewed by Rosco and are recommended as

replacements. It is best to use the heaviest weight

oil that can be safely used for the temperature

range of machine operation. If your machine will

never be used at below 0°F temperatures, we

HYDRAULIC OIL REQUIREMENTS AND APPROVED BRANDS FOR FIELD FILL:

DO NOT MIX manufacturers or grade

weights when adding hydraulic oil.

Be sure

hydraulic oil selection is compatable with

your hydraulic system.

Be sure

to use mineral base hydraulic oil.

Be sure

hydraulic oil selection assistance is from

a reputable supplier.

Be sure

the hydraulic specifications meet or

exceed the following specifications.

Hydraulic oil must provide anti-wear properties

that meet or exceed those found in the API

(American Petroleum Institute) classification SD,

SE or CC crank case oil.

Hydraulic oil viscosity must not fall below 70 SUS

(13 cs) in the reservior under the most adverse

conditions. The best viscosity being 80-300 SUS

(17 cs to 65 cs). The viscosity rating at the lowest

expected start-up temperature should not exceed

10,000 SUS (2158 cs).

Hydraulic oil must have rust and oxidation

inhibitors that will maintain chemical stability. When

changing the hydraulic oil with oil other than the

specific factory fill oil listed below, the hydraulic

system must be completely drained. Be sure to

purge or drain all hoses, cylinders, valves, motors

and pumps of hydraulic oil. All hydraulic oil filters

must also be changed at this time.

recommend that you use a heavier weight oil.

If you are considering using an oil that is not listed,

contact the Rosco factory to obtain the

specifications that the hydraulic oil must meet to

provide the needed lubrication and cooling for the

units’ hydraulic components.

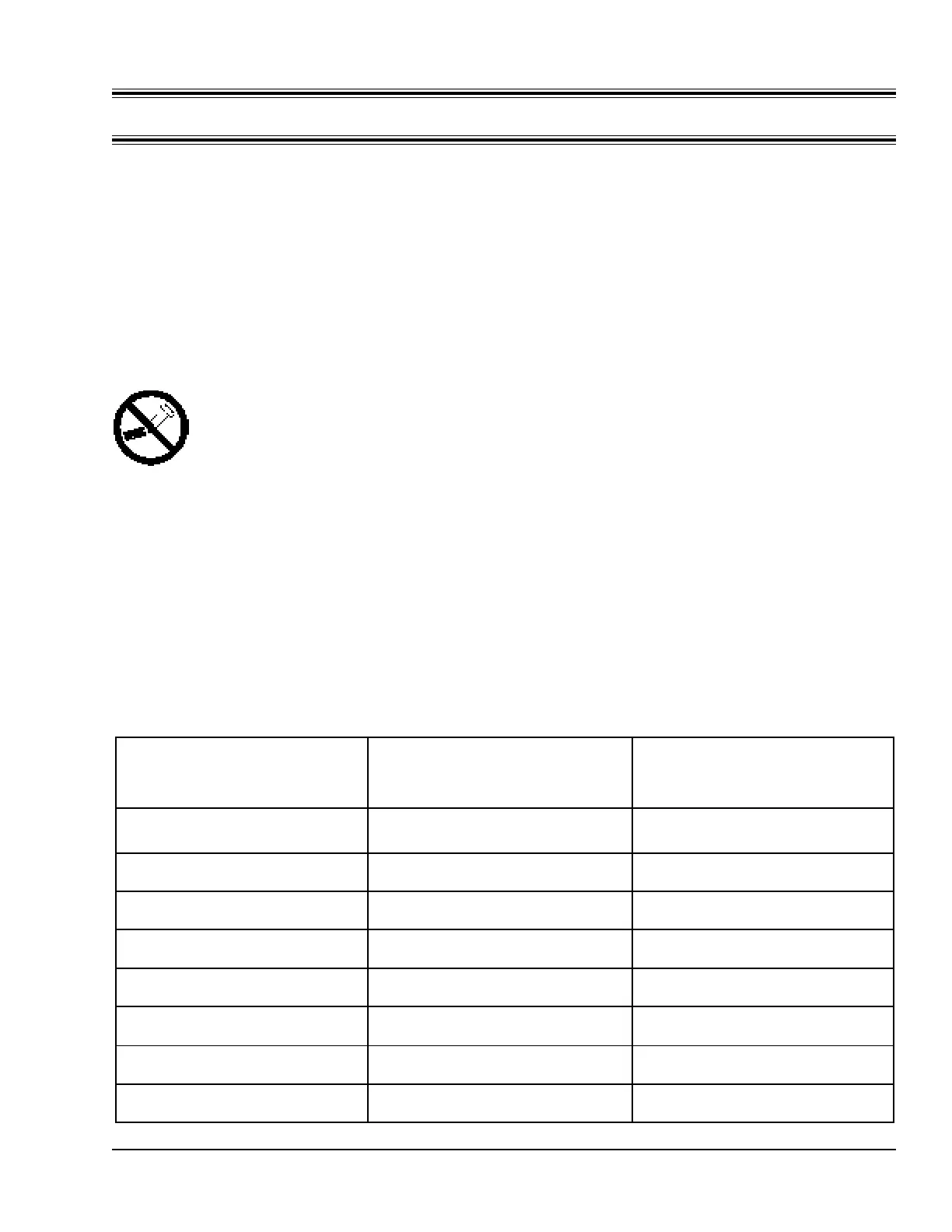

ISO 46 / SAE 20 ISO 68 ISO 100 / SAE 30

AMBIENT TEMP. AMBIENT TEMP. AMBIENT TEMP.

-15° F TO 80° F (-26° TO 27° C) 0° F TO 100° F (-18° TO 38° C) 15° F TO 115° F (-9° TO 46° C)

Special Start-up Below 5° F (-15° C) Special Start-up Below 20° F (-7° C) Special Start-up Below 32° F (0° C)

Hyd Res Temp Max 165° (74° C) Hyd Res Temp Max 186° F (85° C) Hyd Res Temp Max 200° F (93° C)

MOBIL DTE 25 MOBIL DTE 26 MOBIL DTE AW 100/DTE 18M

CITGO AW 46 CITGO AW 68 CITGO AW 100

CONOCO PHILLIPS 46 CONOCO PHILLIPS 68 CONOCO PHILLIPS 100

CHEVRON TEXACO AW 46 CHEVRON TEXACO AW 68 CHEVRON TEXACO AW 100

SHELL TELLUS 46 SHELL TELLUS 68 SHELL TELLUS 100

EXXON NUTO 46 EXXON NUTO 68 EXXON NUTO 100

MAINTENANCE

Loading...

Loading...