RB48 BROOM

ROSCO - A LeeBoy Company

Maintenance

4.8

MAINTENANCE

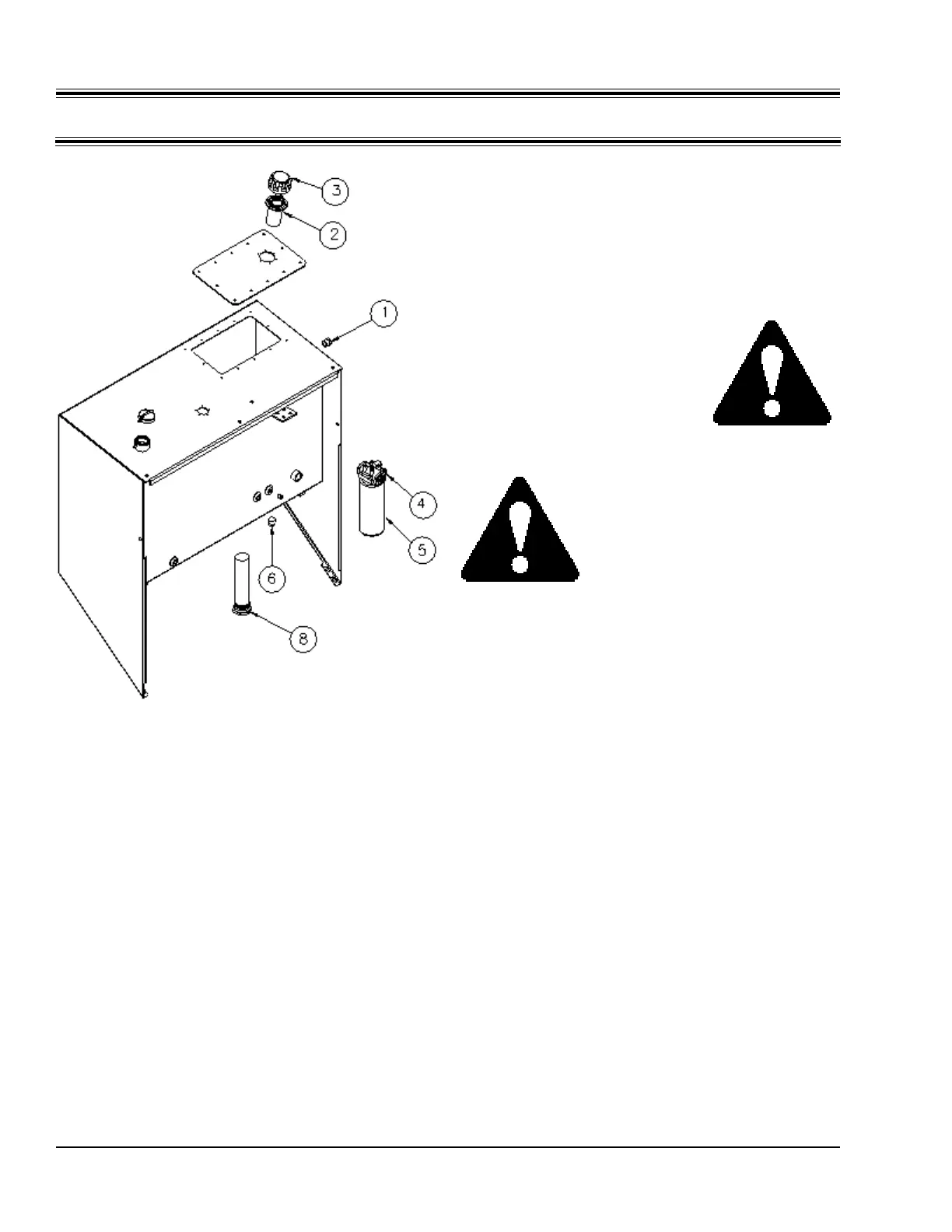

F. Drain and replace hydraulic oil and filter

after the first 100 hours of service, and after every

500 hours of service or seasonally, whichever

comes first. Use genuine Rosco replacement

parts when changing the filter element. Refer to

the Preventive Maintenance Chart at the end of

this section for part number. Drain the hydraulic

oil by removing the plug (6). For convenience, a

customer supplied drain hose can be attached to

drain fluid into a container.

G. The suction strainer (8) should be removed

and cleaned at the 500 hour service interval or

whenever the hydraulic oil is changed. There is no

need to remove and clean suction strainer at the

100 hour service interval.

Hydraulic System Checks

Before each day's use, inspect the ROSCO

Broom for possibile hydraulic leaks. A weekly

check should be performed to make sure that all

hose fittings are secure and tight.

DANGER: Never use your

hand to locate hydraulic leaks.

Hydraulic fluid under pressure

will pierce the skin and is

dangerous. Use a piece of

wood or cardboard to locate

leaks. If hydraulic oil has

pierced the skin, get immediate

medical attention.

DANGER: Always wear eye

protection when inspecting for

leaks in the hydraulic system.

A. If leaking fluid is found, it is probably on the

pressure side of the hydraulic system. Find and

repair the leaking component before starting the

broom.

B. Leaks on the suction side of the hydraulic

system are more difficult to find. Some symptoms

of suction leakage which cause air and dirt to

enter the system are:

- Foaming of hydraulic oil

- Sluggish hydraulic system operation

- Unusual noise in hydraulic pump or motor

This condition is serious since air or dirt

introduced into the hydraulic system causes rapid

component wear and eventual failure.

1. If a suction side leak is suspected, verify

that all reservoir connectors and fittings are

properly tightened.

2. If the problem persists, wrap the suction

side hose and connectors with a high-

quality electrical tape. Start at the pump

inlet(s) and work toward the hydraulic

reservoir.

Figure 4-C

Hydraulic Reservoir

Loading...

Loading...