A4US

US

A4

US A4

US

A4

A4 US

US

A4

US

A4

A4 US

Keeping the World Flowing

3

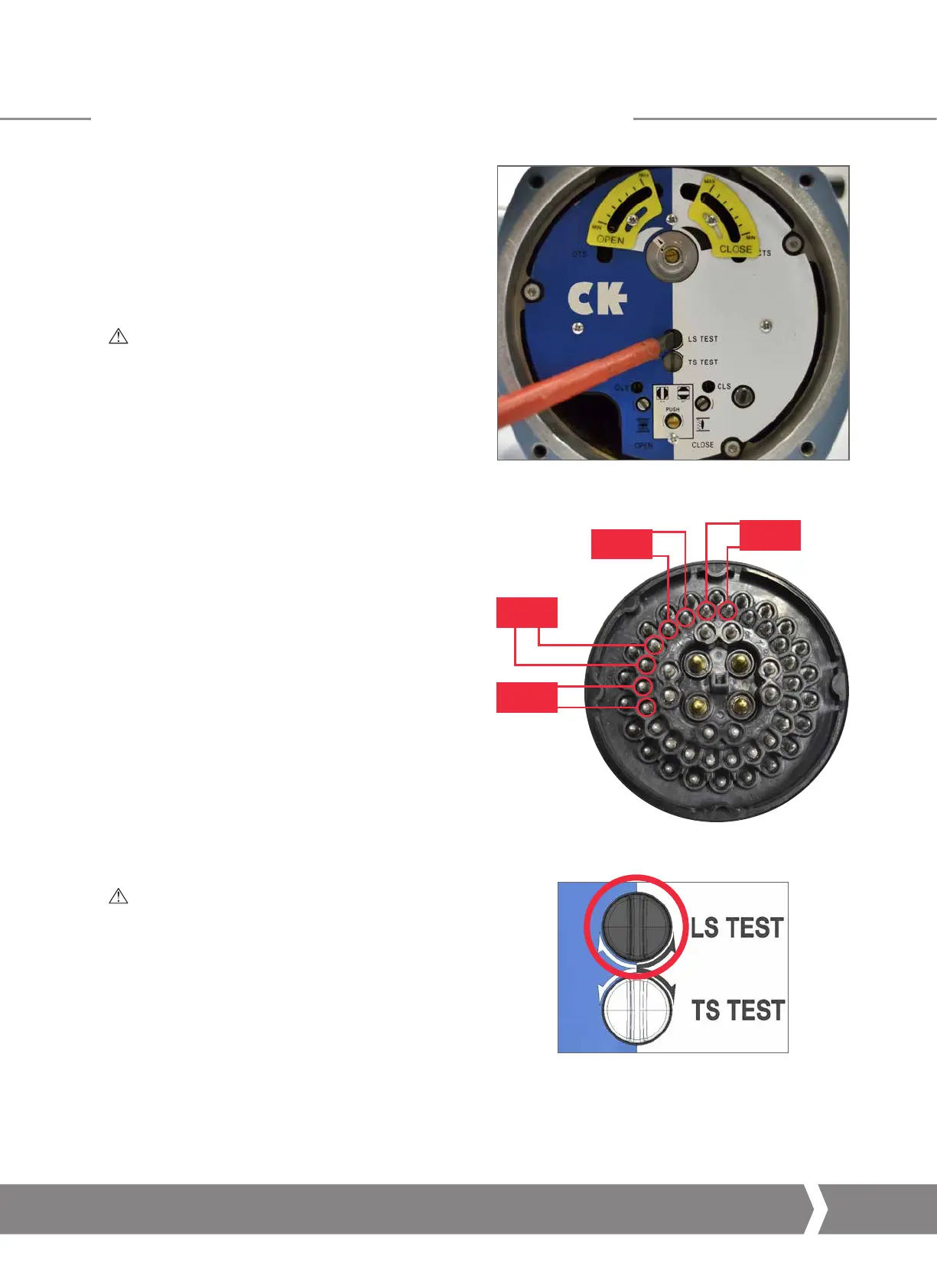

Before following any of the setting instructions included in

this document it is important to pay attention to the warnings

and safety instructions included in PUB111-007 provided with

the actuator.

A 5mm Allen (Hex.) key and 1.0 x 5.5mm flat screwdriver are

required to perform testing of the CK Mechanical

Switch Mechanism.

Test feedback switches

WARNING: Isolate the main power supply and all

control and indication wiring before removing the

Plug & Socket cover

.

1) Undo the four retaining cap screws on the switch

mechanism cover and remove the cover to show the

switch mechanism.

2) Confirm the torque or limit switches are functional by

measuring the relevant feedback terminals on the plug

assembly (see below).

It is not possible to test a switch that is already actuated

by the mechanism (for instance, at the end of travel

limits). To ensure that all switches can be tested correctly,

move the actuator to a mid-travel position and confirm

that none of the switches are active before beginning the

test procedure.

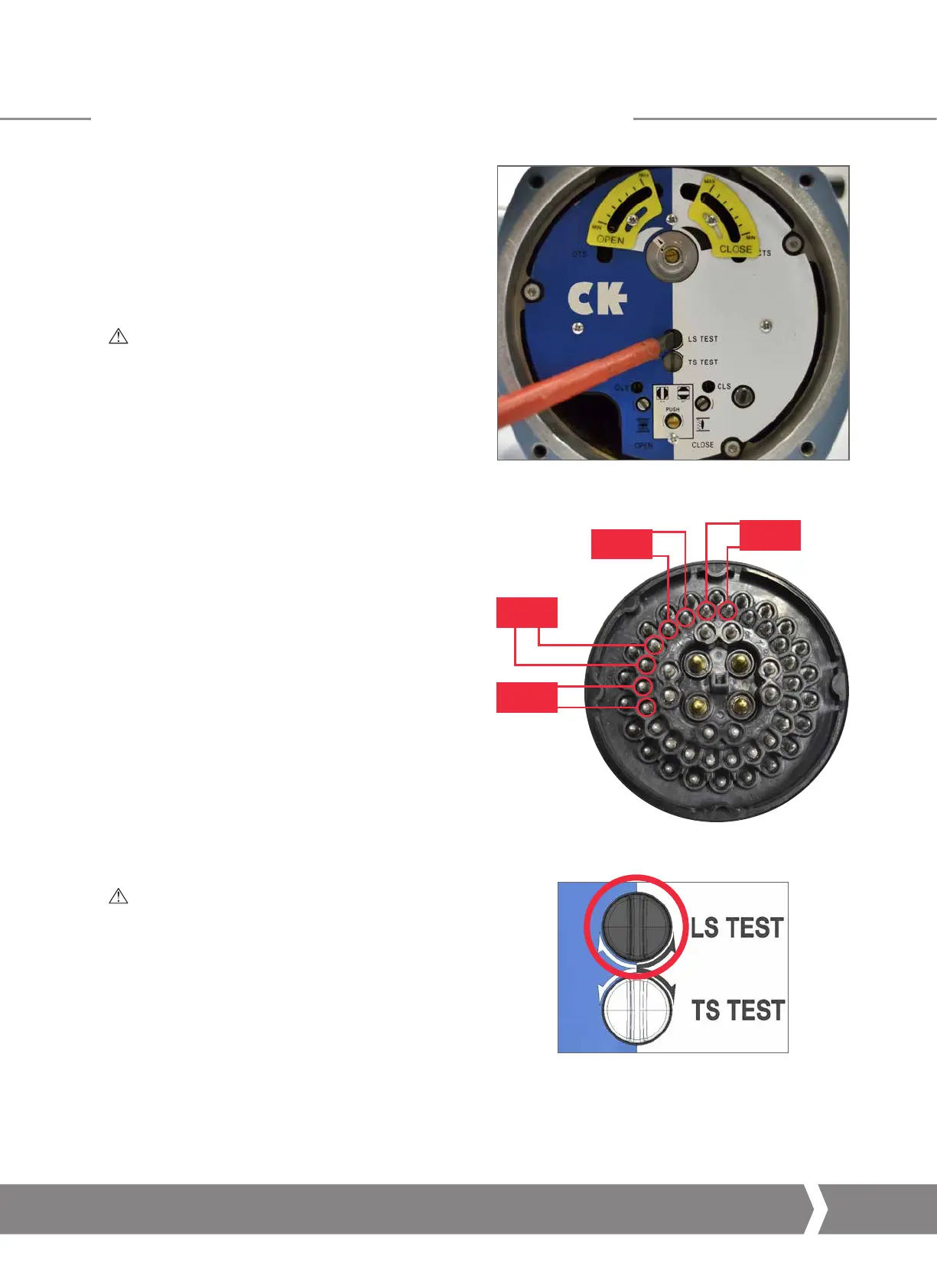

3)

Test position switches in both directions using a flat

screwdriver to turn LS TEST (CW for open, ACW for close).

4) Link a continuity meter across the following pairs of

terminals to test each individual function.

N/C CLS

– Normally Closed (break when active) Close Limit

contact for motor control

N/O CLS

– Normally Open (make when active) Close Limit

contact for feedback indication

N/C OLS

– Normally Closed (break when active) Open Limit

contact for motor control

N/O OLS

– Normally Open (make when active) Open Limit

contact for feedback indication

INFO: It is important to recognise the rotation of the

exposed plug when performing actuator function

diagnostics. The central “U” locating point provides

an orientation reference for this testing procedure.

N/O OLS

N/C OLS

N/O CLS

N/C CLS

19

18

17 16

15

14

12

13

CK Mechanical Switch Mechanism – Switch Testing

Loading...

Loading...