A4US

US

A4

US A4

US

A4

A4 US

US

A4

US

A4

A4 US

CK Standard and CKR Start Up Guide

10

CK Additional Indication Drive – Basic Settings

A 5mm Allen (Hex.) key and 0.8 x 4mm flat screwdriver with at

least 120mm shaft length are required to perform commissioning

of the CK Mechanical Switch Mechanism. A small torch may be

required in environments with low level lighting.

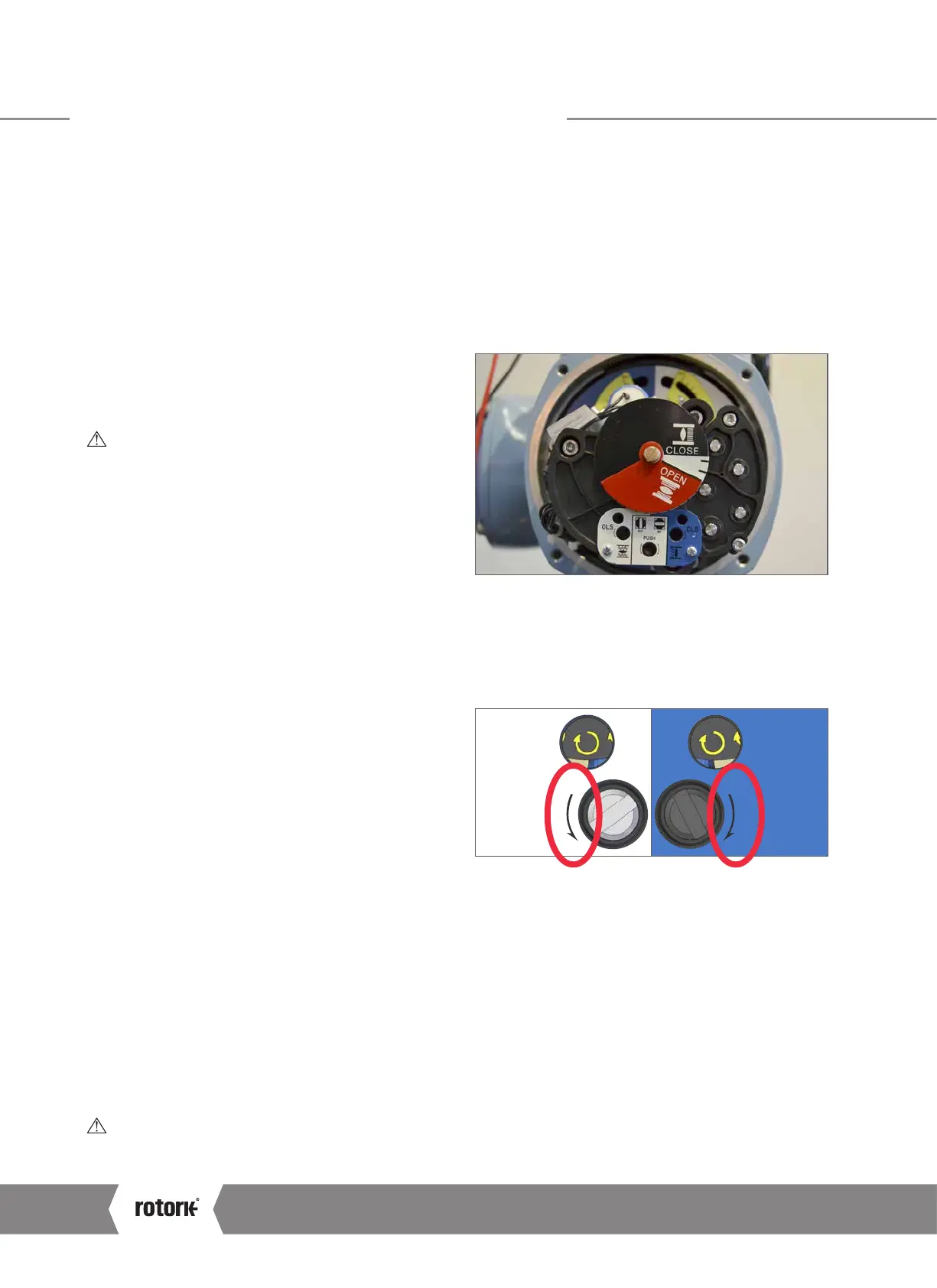

Set Torque Limits

The torque limits can be set using the same method

previously described in this manual at the beginning of the

Basic Settings section. Access to the torque setting inputs is

maintained whilst the AID module is fitted.

Set Position Limits

The position limits can still be set with the CK AID module in

place. The OLS/CLS Indicator windows and adjustment screws

can be accessed through the labelled holes in the AID chassis.

CAUTION: It is important to remove the POT drive

assembly (if fitted) from the drive gearing prior to

setting the position limits. Refer to Setting the POT

section, steps 1 and 2 for instructions on adjusting

this component.

1) Move the actuator to the valve CLOSED position using the

handwheel.

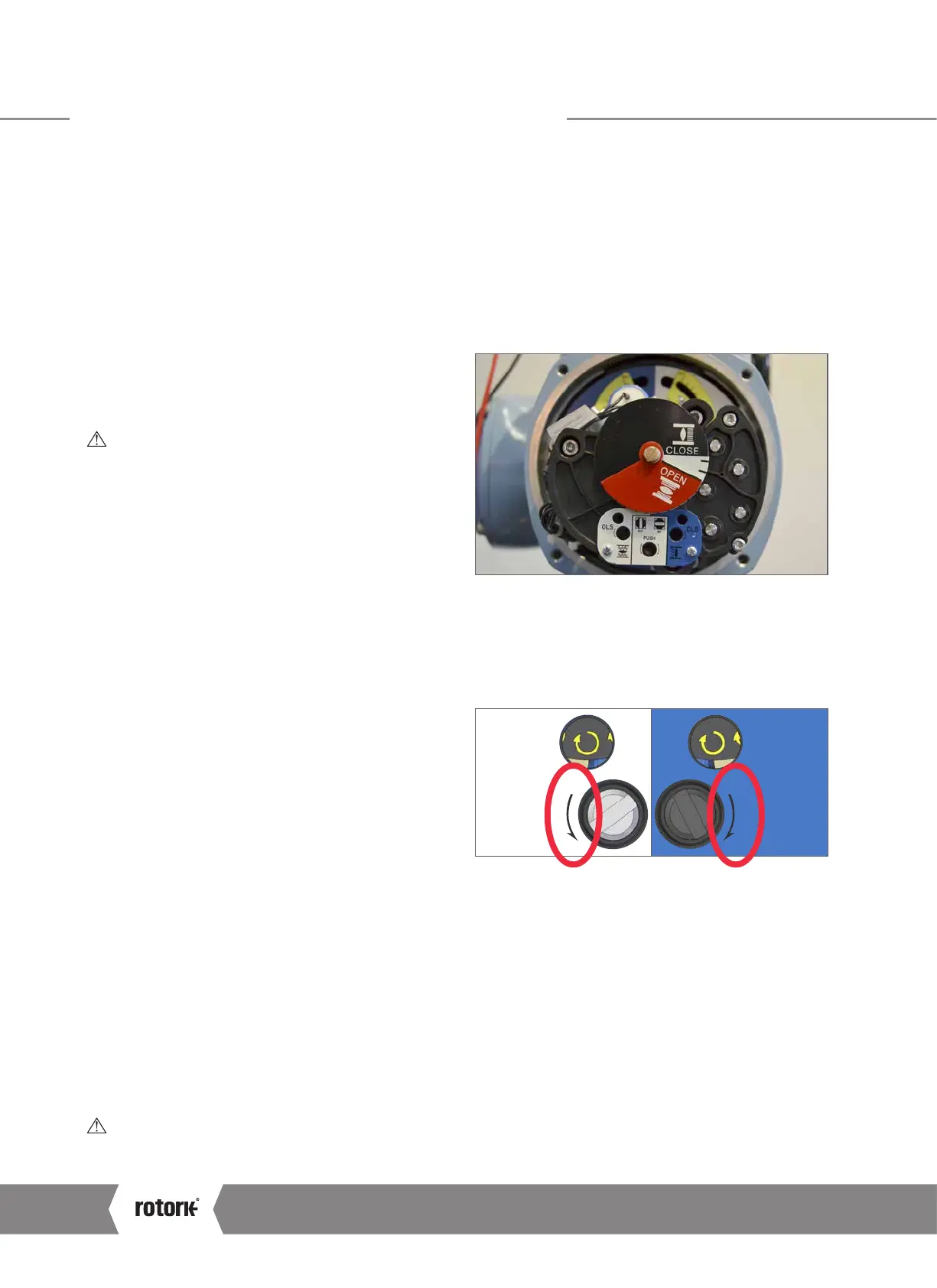

2)

Using a flat screwdriver, depress the Drive Clutch Shaft and

rotate to the “Set” position as shown on the AID faceplate.

3) The CLS Adjustment Screw must now be rotated

to engage the closed limit switch inside the switch

mechanism. The CLS Indicator Window will show one of

four possible symbols. Please refer to Figure 2 on page 11

for direction input.

4)

Depending on where the mechanism is in the cycle, it is

possible that the switch will be approached from the wrong

direction, in this case it is necessary to move through the

limit and approach it from the correct direction. This avoids

the need to wind through the whole mechanism to reach

the limit position. The correct direction to approach the limit

is shown by the arrow next to the Adjustment Screw input.

5) Perform two checks to confirm the CLOSED limit position

switch has been made correctly.

a. The feel of the Adjustment Screw will noticeably

change providing more mechanical resistance at the

switching point of the contact.

b. Use a continuity meter on the appropriate terminals –

12 & 13 for motor control and 14 & 15 for indication

feedback to check the switch is engaged.

6)

Using a flat screwdriver, depress the Drive Clutch Shaft and

rotate to the “Run” position as shown on the AID faceplate.

7) Rotate the CLS and OLS Adjustment Screws a small

amount in both directions to re-engage the mechanism

drive. A click will be heard as the drive drops back into

engagement and the adjustment screws will no longer

move in either direction.

CAUTION: This must be done or the limit will be lost

when the actuator is moved.

Loading...

Loading...