A4US

US

A4

US A4

US

A4

A4 US

US

A4

US

A4

A4 US

Keeping the World Flowing

5

A

B

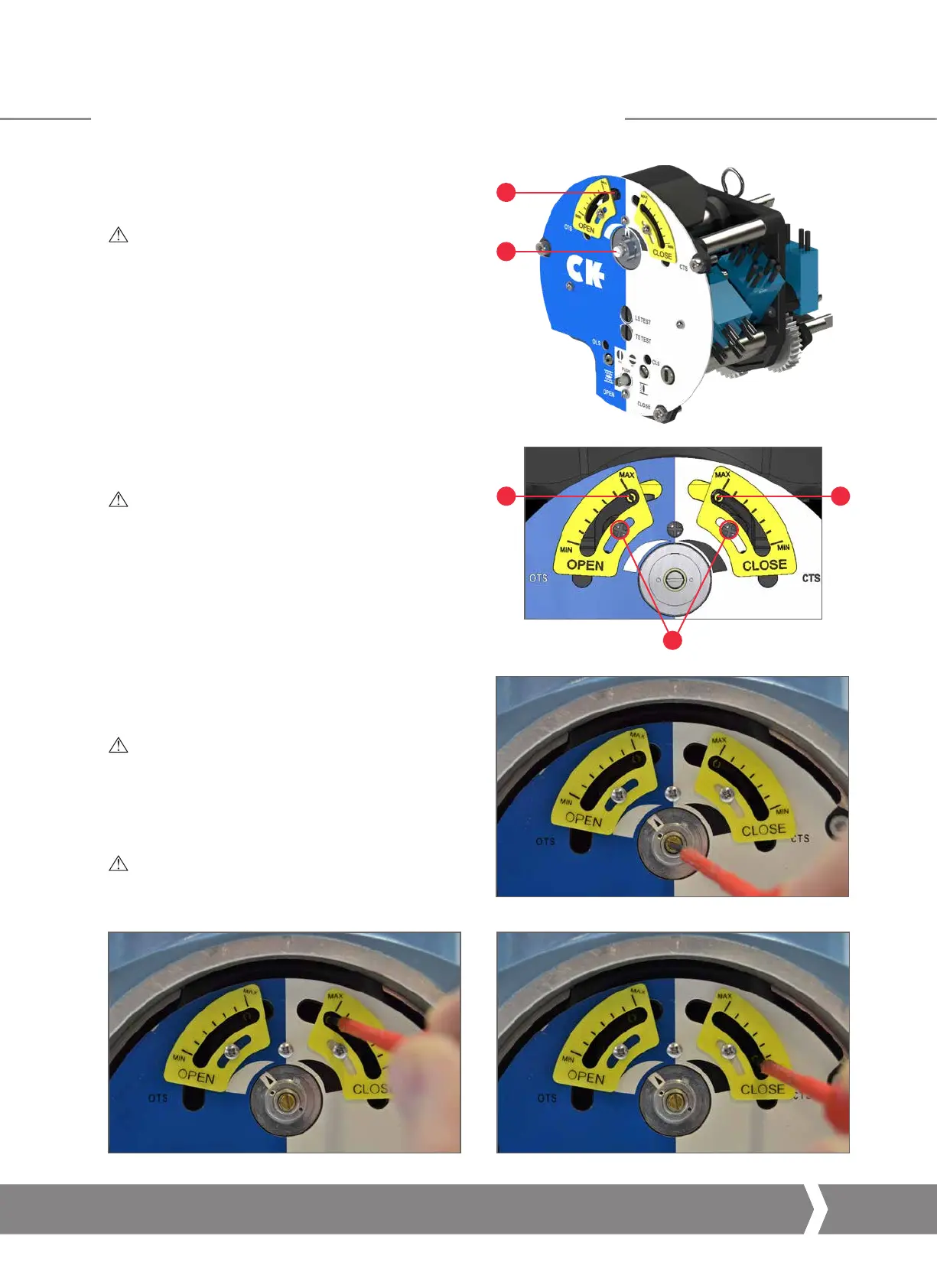

CK Mechanical Switch Mechanism – Basic Settings

A 5mm Allen (Hex.) key and 0.8 x 4mm flat screwdriver are

required to perform commissioning of the CK Mechanical

Switch Mechanism.

INFO: For CK Standard and CKR actuators, the

required end of travel action (torque or position)

is determined by the set of switches cabled to the

controlling switch gear - refer to actuator terminal

plan and site field wiring.

Set Torque Limits

A Indicator/Adjustment Point

B Torque Cam Clutch Screw

C Open Torque Adjustment Point

D Close Torque Adjustment Point

E Factory Calibration Fixings

WARNING: Do not adjust the fixings or position of

the yellow torque indicator plates. These are factory

configured and should not be removed under any

circumstance.

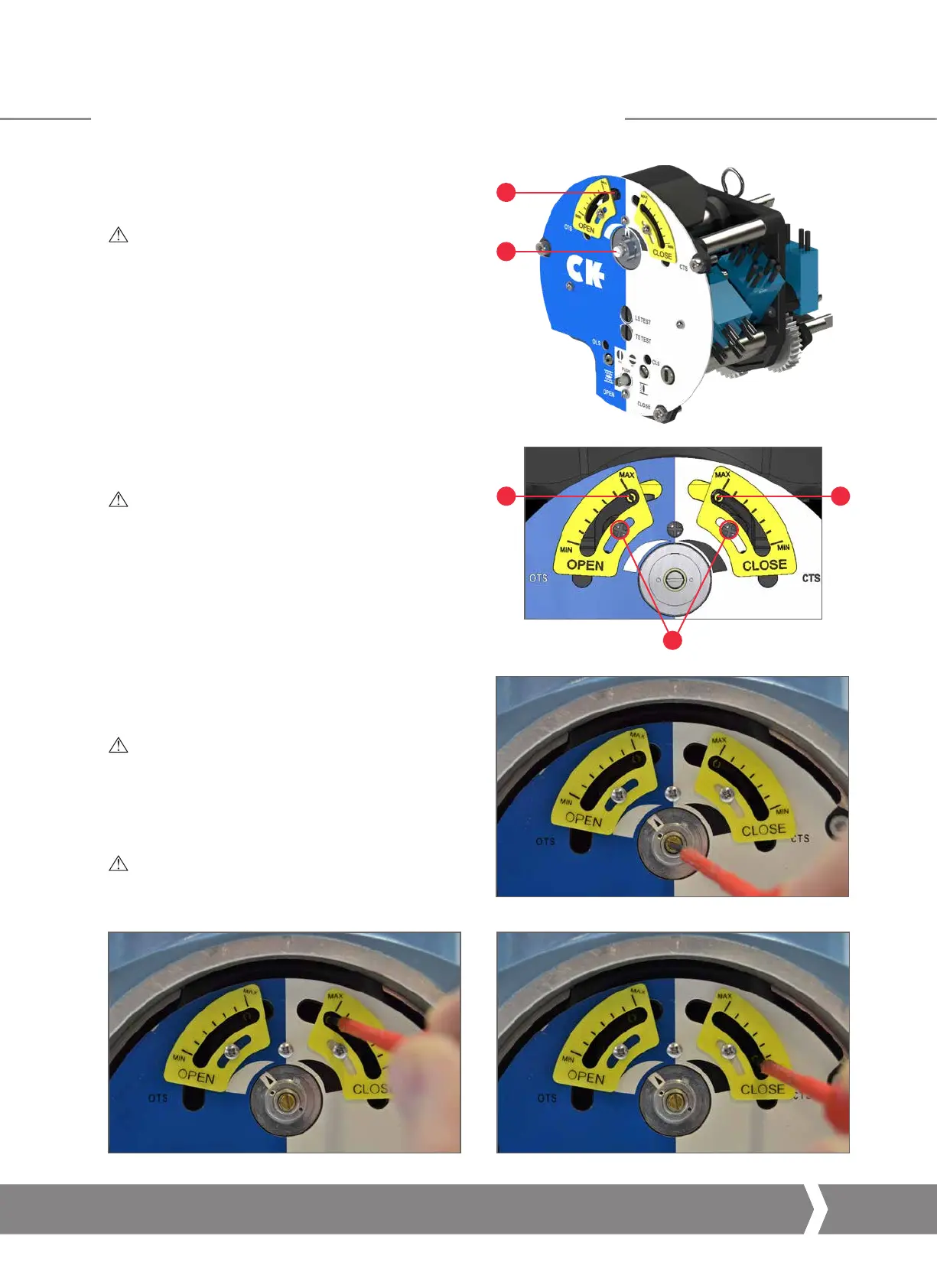

1) Move the valve to a mid-travel position and loosen the

Torque Cam Clutch 1.5 turns using a flat screwdriver.

2) Adjust each Torque Cam to the desired value - between

min. (40%) & max. (100%) - by moving the cam using a

screwdriver on the adjustment point.

CAUTION: To avoid introducing an offset to the set

value when adjusting the torque trip limits. Ensure

the screwdriver remains perpendicular to the switch

mechanism faceplate.

3) Tighten the Torque Cam Clutch Screw once both torque

trip limits have been set.

CAUTION: Tighten the Torque Cam Clutch Screw

until the spring washer is fully deformed under the

screw head.

C D

E

Loading...

Loading...