102 EB 8389-1S EN

Appendix

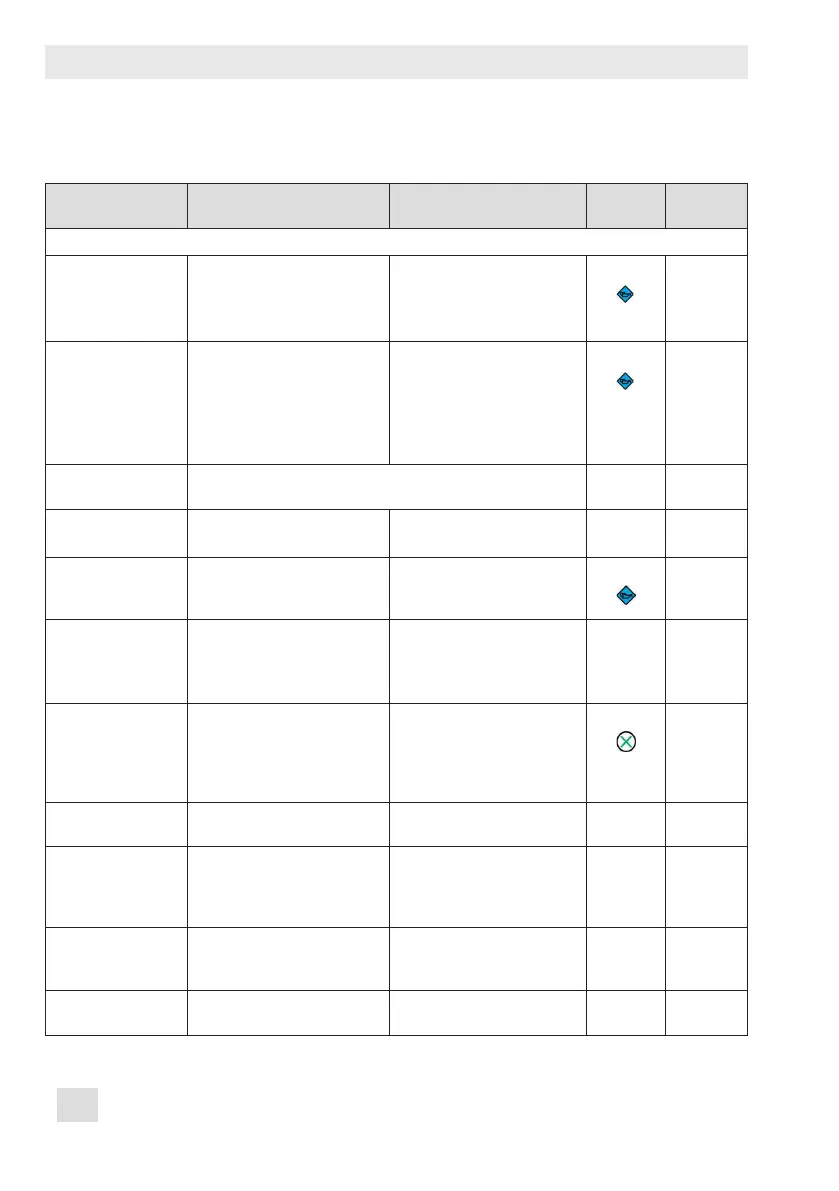

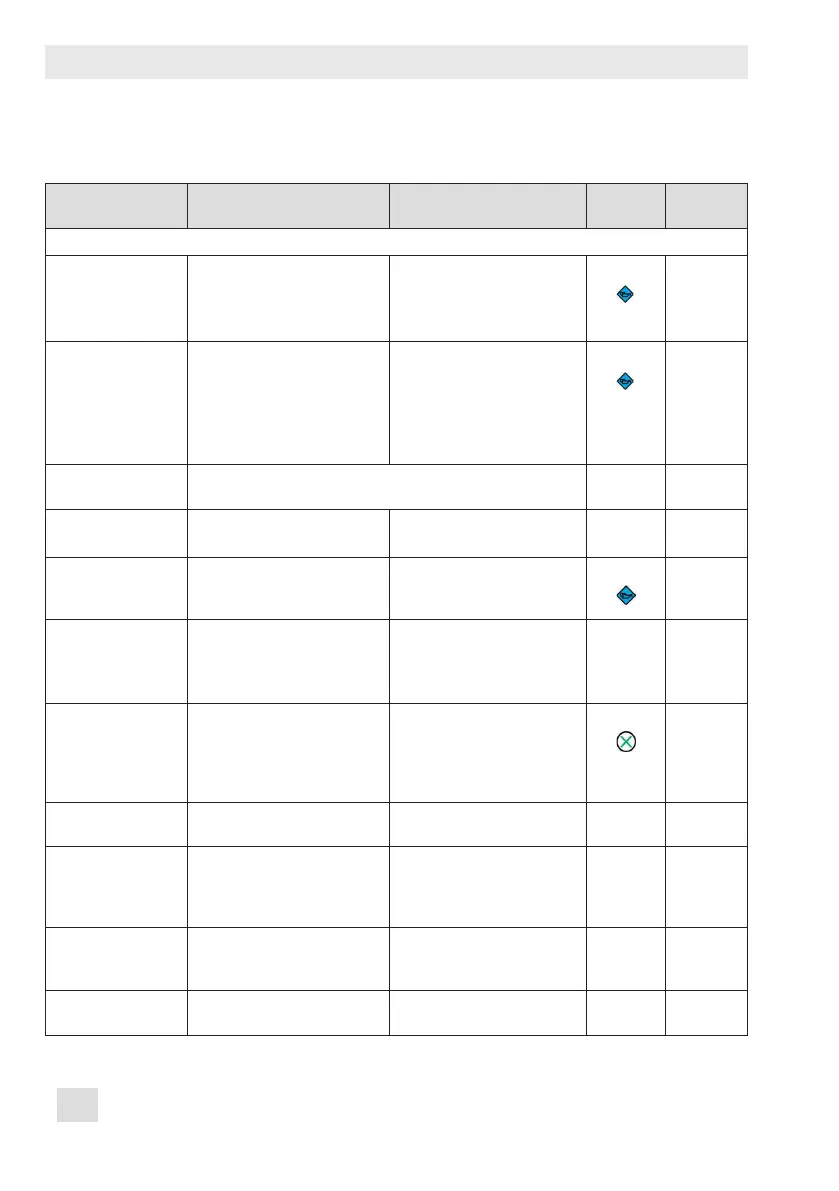

17.2 Error messages and recommended corrective action

Message Possible reasons Recommended action

Status

classication Single reset

Diagnostics > Monitoring > Positioner

Control loop (Code 57) − Actuator is blocked.

− Positioner attachment has shifted

subsequently.

− Insufcient supply pressure

− Check attachment.

− Check supply pressure.

•

[ ]

–

Zero point (Code 58) − Mounting arrangement or link-

age has slipped.

− Valve trim, particularly with soft

seat, is worn.

− Check valve and positioner at-

tachment.

− Calibrate zero.

We recommend to re-initialize the

positioner if zero deviates by more

than 5 %.

•

[ ]

•

Inconsistent data

memory (Code 59)

The error is detected by automatic monitoring and corrected automatically. – •

Internal device error

(Code 60)

− Electromagnetic interference − Reset initialization.

− Re-initialize positioner.

– •

Kp too low (Code 61) Proportional-action coefcient Kp

level lower than 3 was detected dur-

ing initialization.

− Activate volume restriction in

positioner output.

•

[ ]

•

x signal (Code 62) − Actuator's measured value re-

cording failed.

− Conductive plastic element de-

fective.

− Return positioner to SAMSON

for repair.

– –

w too small (Code 63) − The set point (w) is lower than

3.7mA.

This state is indicated on the posi

-

tioner display by LOW blinking.

− Check set point (w). If neces-

sary, restrict lower limit of cur-

rent source to ensure that a cur-

rent below 3.7mA cannot be

issued.

•

[ ]

–

i/p converter (Code 64) Current circuit of i/p converter inter-

rupted.

R

eturn positioner to SAMSON for

repair.

– –

Hardware (Code 65) Conrm error and select 'Automat

-

ic' operating mode. If not success-

ful, reset initialization and re-initial-

ize the positioner.

– •

C

ontrol calculation

(Code 67)

Conrm error. If this is not possible,

return positioner to SAMSON for

repair.

– •

Pressure sensor

(Code72)

Pressure sensor(s) for supply air

and/or signal pressure defective

Return positioner to SAMSON for

repair.

– –

Appendix

Loading...

Loading...