EB 8389-1S EN 55

Leakage sensor

Phase 2: A 0.30 % band is placed around

the last set point that the valve moved to.

One third of this band lies in front of the set

point that the valve moved to and two thirds

of the band lies behind it. The band itself is

subdivided into eleven xed points. Each

xed point is located at a distance of 0.03%

to the next point. The valve moves to the new

xed points one after the other. After reach-

ing a xed point and after the 'Settling time

before sound level measurement' has

elapsed, the leakage sensor measures the

sound pressure level.

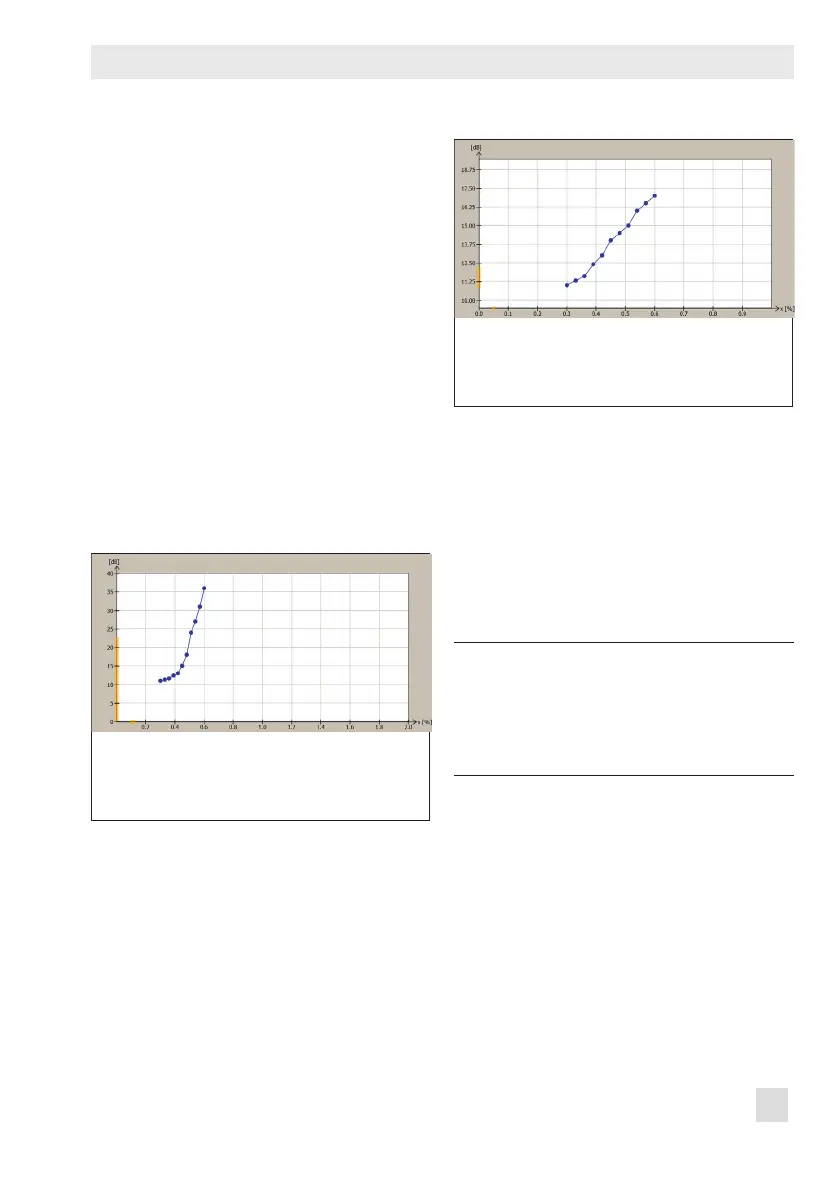

The manufacturer reference test is successful

when the difference between the rst and last

newly dened points is larger or equal to the

adjusted 'Sensitivity sound level'.

Phase 2 successful: The 'Sensitivity sound level'

(10 dB) is reached between the rst and last

newly dened points. The manufacturer test is

successfully completed.

If the 'Sensitivity sound level' is not reached

after the valve has moved to all eleven newly

dened points, then the change in sound

pressure level is too low. In this case, phase

3 starts.

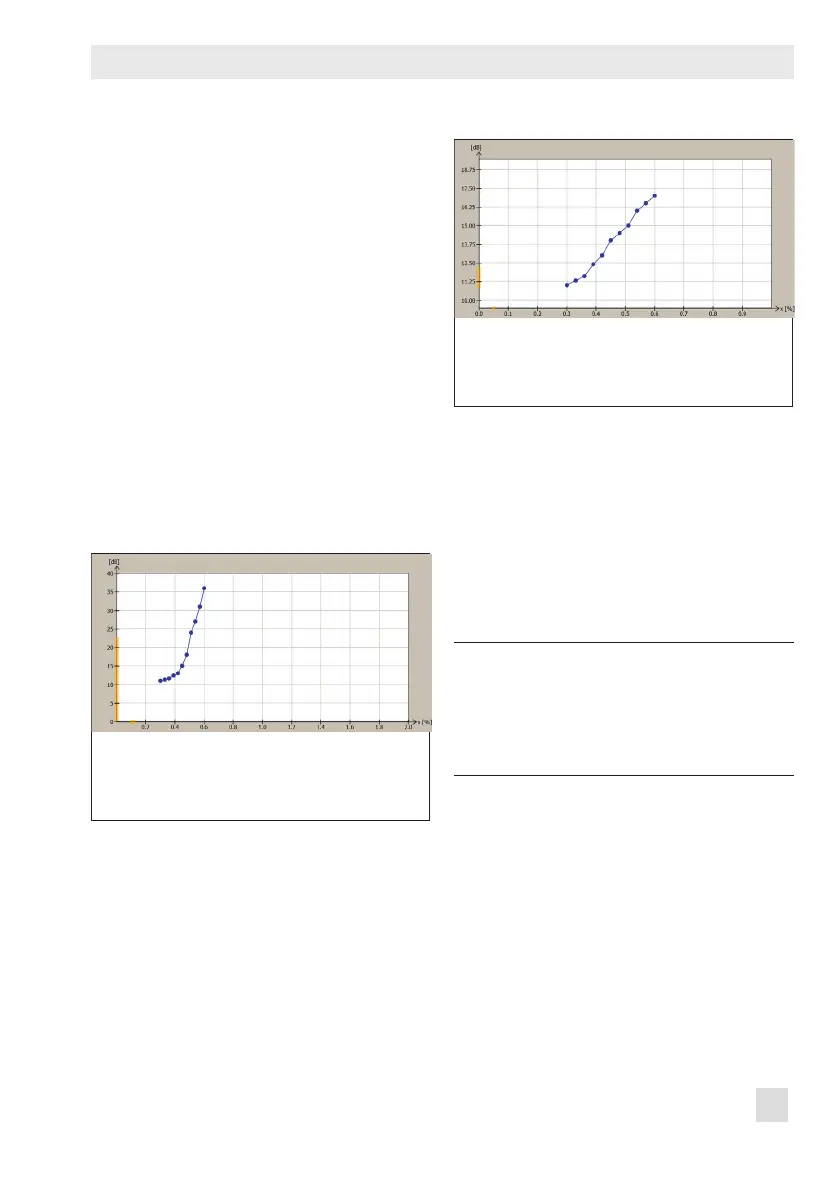

Phase 2 not successful: The difference in sound

pressure level between the rst and last newly

dened points is lower than 'Sensitivity sound

level' (10 dB). Phase 3 starts.

Phase 3: The valve moves to the set points

valid for phase 1 one after the other. This is

plotted in a sound level vs. travel graph. The

graph shows where the point of activation is

and to which value the 'Sensitivity sound lev-

el' must be reduced to allow the test to be

completed successfully.

Dening parameters

Note:

The parameters can only be dened in

TROVIS-VIEW4 after the 'Positioner

accessories identication' has been set

to 'Leakage sensor'.

1. Switch to manual mode.

2. Dene the parameters for the manufac-

turer reference test. Refer to Note con-

cerning editing set points.

3. Start manufacturer reference test.

The start of the reference test is docu-

mented in the Time stamp.

'D8' and 'TEST' are indicated in alternat-

ing sequence on the positioner display.

Loading...

Loading...