4-1

EB|LTR|43_EN

May 2023 edition

Subject to technical changes

Shipment and on-site transport

4 Shipment and on-site transport

The work described in this chapter may only be performed by

specialist personnel qualifi ed to perform the corresponding task.

4.1 Accepting delivery

Perform the following steps after receiving the goods:

1. Check the scope of supply. Compare the data on the butterfl y

valve type plate with the delivery note. For details about the

type plate, see Chapter “2 Markings on the device”.

2. Check the supply for transport damage. Report transport

damage through the nearest SAMSON offi ce to SAMSON

LEUSCH and the transport company, see the delivery note.

3. Select suitable lifting equipment and load handling devices

according to the weight and dimensions of the valve to be

transported and lifted, see the transport documentation and

Chapter “3.4 Technical data”.

4.2 Unpacking the valve

Observe the following procedures:

Ö Unpack the valve directly before lifting for installation into the

pipe.

Ö Check the valve for damage.

Ö Use suitable transport equipment for on-site transport.

Ö Only remove the protective caps on the butterfl y valve inlet

and outlet directly before installation into the pipe. They pro-

tect the butterfl y valve against damage by preventing the en-

trance of foreign material.

Ö Dispose of the packaging according to local regulations.

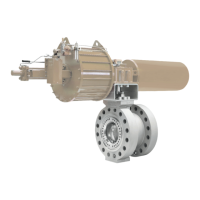

4.3 Transporting and lifting the valve

Danger due to falling of suspended loads!

Ö Do not stand under suspended loads.

Ö Secure the transport paths

Overturning of the lifting equipment and damage to the load

lifting equipment by exceeding the lifting capacity!

Ö Only use approved lifting equipment and load lifting equip-

ment whose lifting capacity corresponds at least to the weight

of the valve and the packaging if applicable.

Danger of injury due to tipping of the valve!

Ö Observe the centre of gravity of the valve.

Ö Secure the valve against tipping and twisting.

DANGER

WARNING

Danger of injury due to incorrect lifting without lifting equip-

ment!

When lifting the valve without lifting equipment, injuries may oc-

cur, especially in the torso area, depending on the weight of the

valve.

Ö Observe the occupational health and safety regulations ap-

plicable at the installation site.

Damage to the valve due to improper fastening of the sling!

The lifting eye/eyebolts on the actuators are used only for actua-

tor assembling and disassembling as well as for lifting the actua-

tor without the butterfl y valve. These fastening points are not in-

tended for lifting the complete valve.

Ö When lifting the valve, make sure that the entire load is car-

ried by the sling that is fastened to the butterfl y valve body.

Ö Do not fasten the load-bearing sling to the actuator, hand

wheel or other components.

Ö Observe the conditions for lifting, see Chapter 4.3.2.

Ö Do not use the control air lines, accessories or other compo-

nents with safety functions for suspension or damage them.

4.3.1 Transporting the valve

The transport notes from the packaging (e.g. wooden box) must

be followed. The valve can be transported using lifting equipment

such as a crane or a forklift.

Ö Comply with the transport conditions.

Transport conditions

Ö Protect the valve against external infl uences, such as impacts.

Ö Do not damage the corrosion protection (paint, surface coat-

ing). Report any damage immediately and remedy it after

consultation.

Ö Protect the pipes and any attachments from damage.

Ö Protect the valve against moisture and dirt.

Ö When the valve is in the standard version, the permissible

transport temperature is from –20 to +65°C.

4.3.2 Lifting the valve

When installing the valve in the pipe, suitable lifting equipment

should be used, such as a crane or a forklift. Use suitable tested

slings and suitable fastening to make sure that the surfaces and

contact surfaces are not damaged, and that no other damage

occurs to the valve (e.g. actuator accessories, piping, sealing ele-

ments).

WARNING

NOTE

Loading...

Loading...