9-2

EB|LTR|43_EN

May 2023 edition

Subject to technical changes

Servicing

− Certain test results certifi ed by SAMSON LEUSCH are no

longer valid when performing maintenance work on the

actuator. This includes the test for seat leakage and the leak

test (outer tightness).

− If maintenance and repair work is performed without

approval from the After Sales Service of SAMSON LEUSCH,

the product guarantee will be voided.

− For spare parts, only use original parts from SAMSON

LEUSCH that correspond to the original specifi cation.

9.1 Periodic tests

Depending on the conditions of use, the actuator must be

checked at defi ned intervals in order to take remedial measures

prior to possible malfunctions. The plant operator is responsible

for preparing a suitable test plan in consideration of the

documentation of the utilised components.

After Sales Service can provide you with support for creating a

test plan specifi c to your plant. Contact the nearest SAMSON

offi ce.

SAMSON LEUSCH recommends the following inspections that

can be carried out during operation:

Test

Measures in the case of a negative test

result

Check the butterfl y valve for

exterior damage (e.g. corro-

sion).

Remedy any damage immediately, if

possible. If required, decommission the

actuator, see chapter 10.

Check the imprints and im-

pressions on the actuator,

adhesives and signs for legi-

bility and completeness.

Request a replacement for damaged,

missing or faulty signs or adhesives and

replace them.

Clean text that is illegible due to dirt.

Check the butterfl y valve for

leaks from the outside.

Tighten the packing, see Chapter 5.1.1.

Tighten the screw connections on the

bonnet and extension, see Chapter 5.1.1

or replace the corresponding seals.

Check the fl ange connection (tightening

torques) and replace the seals on the

fl ange connection if necessary, see

Chapter 9.4.

Check the actuator, attach-

ments and their piping for

leaks.

Proper tightening of the pipe connec-

tions.

In the case of defective components, con-

tact SAMSON LEUSCH through the

nearest SAMSON offi ce.

Check the inner tightness of

the butterfl y valve.

Rinse the plant part with the butterfl y

valve open, to remove any dirt and/or

deposited foreign material from between

the seat and the seal ring.

Check the end position to the closed po-

sition and adjust if necessary.

Replace the seat and seal ring, see

Chapter 9.3.4

Tip

Test

Measures in the case of a negative test

result

Check the rotary movement

of the actuator for a smooth,

rotating movement.

Check the packing for correct tightening

torque and tighten correctly if necessary,

see Chapter 5.1.1.

Check the functionality/energy supply of

the actuator and the attachments and

take suitable measures if necessary.

If the actuator shaft is blocked, contact

SAMSON LEUSCH immediately through

the nearest SAMSON offi ce.

Decommission the actuator, see chapter

10. Then determine the cause and reme-

dy it, see Chapter 8.1.

If required, check the fail-

safe position of the actuator

(partial stroke/full stroke

test).

Contact SAMSON LEUSCH through the

nearest SAMSON offi ce.

9.2 Preparing maintenance work

Ö Get the material and tools ready that are required for the

maintenance work.

Ö Identify the components that should be checked or serviced.

Ö If components are to be replaced, it is recommended to

contact SAMSON LEUSCH through the nearest SAMSON

offi ce.

Ö Decommission the actuator, see chapter “10

Decommissioning”.

Ö Interrupt the pneumatic energy to the actuator (deenergise

and depressurise).

9.3 Maintenance work

9.3.1 Maintenance work on the attachments

Observe the documentation for the corresponding attachments.

9.3.2 Maintenance work on the actuator

Observe the documentation for the corresponding actuator.

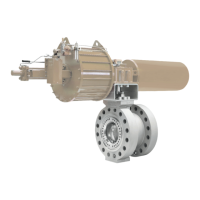

9.3.3 Maintenance work on the butterfl y

valve in an installed condition

At least one SAMSON LEUSCH Seal Kit is required to perform

this work.

SAMSON LEUSCH recommends the procurement of a

corresponding rep-kit, see Chapter “15.3 Spare parts”.

Loading...

Loading...