1-4

EB|LTR|43_EN

May 2023 edition

Subject to technical changes

Safety instructions and safety measures

Danger of injury due to pressurised components and escaping

medium!

Ö Do not loosen pressurised components.

Danger of injury due to incorrect operation, use or installation

caused by illegible information on the butterfl y valve!

Over time, imprints or impressions on the valve can soil the

adhesives and signs or make them illegible for other reasons so

that dangers are not recognised and necessary operational

messages cannot be followed. Danger of injury can occur.

Ö Keep all relevant markings on the device legible at all times.

Ö Damaged, missing or faulty signs or adhesives must be

replaced immediately.

Functional impairment of the butterfl y valve due to oil leaking

from the hand pump!

Ö Observe the agreed and documented actuator/valve

alignment.

Dangers due to use of the butterfl y valve as an end fi tting!

During normal operation, in particular with gaseous, hot and/or

hazardous media, spraying medium can cause hazards.

Ö A blind fl ange must be assembled on the free connecting

pieces or the butterfl y valve must be secured against

unauthorised actuation.

Ö If a butterfl y valve is used as an end fi tting in a pressurised

line is opened, this may only be done with extreme caution

so that the escaping medium does not cause any damage.

1.3 Notes regarding possible property

damage

Damage to the butterfl y valve due to contamination (e.g. solid

particles) in the pipes!

The plant operator is responsible for cleaning the pipes in the

plant.

Ö Rinse the pipes prior to commissioning.

Damage to the butterfl y valve due to unsuitable medium

properties!

The butterfl y valve is designed for a medium with certain

properties.

Ö Only use a medium that corresponds to the design criteria.

Damage to the butterfl y valve and leakage due to excessively

high or low tightening torques!

The butterfl y valve components must be tightened with specifi c

torques. Excessively tightened components are subject to

increased wear. Insuffi ciently tightened components can cause

leakage.

Ö Comply with the specifi ed tightening torques, see Chapter

“15.1.1 Tightening torques”

WARNING

NOTE

Damage to the butterfl y valve due to unsuitable tools!

Unsuitable tools can damage the valve.

Ö Suitable commercially available tools are needed to work on

the butterfl y valve, see Chapter “15.1.3 Tools”.

Damage to the butterfl y valve due to unsuitable lubricants!

The functionality of the butterfl y valve is ensured only by using a

certain lubricant. Unsuitable lubricants can corrode and damage

the surface.

Ö The butterfl y valve material requires suitable lubricants, see

Chapter “15.1.2 Lubricants”.

Medium contamination due to unsuitable lubricants and

contaminated tools and components!

Ö If required, for example for oxygen applications, keep the

butterfl y valve and utilised tools free from solvents and

greases.

Ö Only use suitable lubricant, see Chapter “15.1.2 Lubricant”

1.4 Warning notes on the device

Warning of moving parts.

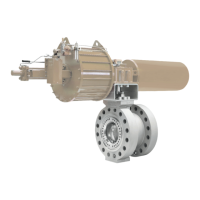

Figure|1-1: Example of the warning information

Figure|1-2: Position on the valve

There is a risk of crushing due to the rotation of the shaft,

especially during fast rotation movements, when reaching into

the bracket as long as the pneumatic energy is connected to the

actuator, see

LW 10018, Paragraph 1.3.7.

NOTE

Loading...

Loading...