5-5

EB|LTR|43_EN

May 2023 edition

Subject to technical changes

Installation

If the actuator is delivered separately from the butterfl y valve or if

it must be disassembled, actuator assembly may be carried out

only by personnel trained by SAMSON LEUSCH.

Perform the following tests to test the function of the actuator pri-

or to commissioning or recommissioning:

5.4.1 Pressure and leak test

Damage to the butterfl y valve due to a sudden pressure increase

and resulting high fl ow speed must be avoided!

Ö Observe the data on the type plate.

Damage to the butterfl y valve due to excessively high or low

tightening torques!

The butterfl y valve components must be tightened with specifi c

torques, see Chapter “15.1.1 Tightening torques”.

Excessively tightened components are subject to increased wear.

Insuffi ciently tightened components can cause leakage.

Ö Observe the specifi ed tightening torques.

The plant operator is responsible for performing the leak test and

selecting the test procedure. The leak test must comply with the

national and international standards and regulations applicable

at the installation site!

During the pressure test and leak test from the outside, the butter-

fl y valve wedge-lock-washer must be brought into the open posi-

tion.

Upon request, the After Sales Service can provide you with sup-

port for the planning and implementation of a leak test specifi c to

your plant. Contact the nearest SAMSON offi ce.

The tightness of the packing, bonnet, fl ange and optional body

extension must be checked.

In the case of impermissible leakage, proceed as follows:

Tighten the packing (8)

Ö Tighten the stuffi ng box nuts (56) alternately and evenly using

the specifi ed torques, see Chapter “15.1.1 Tightening tor-

ques” or

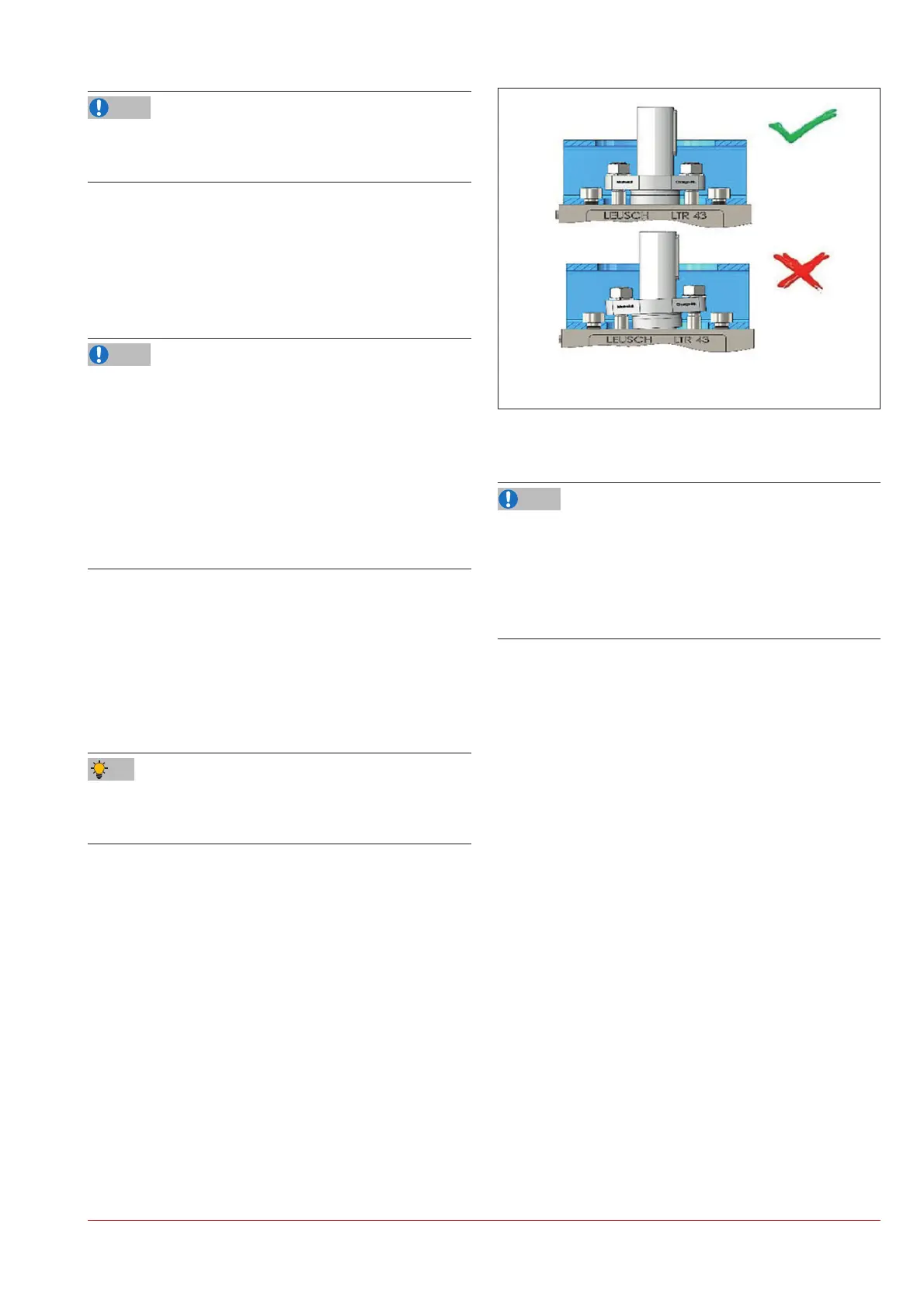

LW-10006 or LW-10007. Avoid tilting

NOTE

NOTE

Tip

Figure|5-3: Correct tightening of the packing

Ö Open and close the actuator completely multiple times, if

possible.

Ö Repeat steps 1 and 2 until the required tightness is achieved.

Functional impairment of the butterfl y valve due to increased

friction resulting from an excessively tightened stuffi ng box!

Ö Make sure that the actuator shaft is able to move smoothly af-

ter tightening the stuffi ng box.

Ö If the adjustable packing is not correctly sealed, contact

SAMSON LEUSCH through the nearest SAMSON offi ce.

Tighten the bonnet (7)

Ö Tighten the bonnet screws (53) with the specifi ed tightening

torque, see Chapter “15.1.1 Tightening torques” or

LW-

10017, Annex 15.2.

Ö In the case of insuffi cient tightness, contact SAMSON LE-

USCH through the nearest SAMSON offi ce.

Tightening the fl ange

Ö Tighten the fl ange screws with the specifi ed torque.

Ö If the seal is not suffi cient, the fl anges and fl ange seals must

be checked for damage and replaced if necessary.

Optional body extension (15) (insulation part)

Ö Tighten the nuts (63) with the specifi ed tightening torque, see

Chapter “15.1.1 Tightening torques” or

LW-10017, An-

nex 15.2.

Ö In the case of insuffi cient tightness, contact SAMSON LE-

USCH through the nearest SAMSON offi ce.

NOTE

Loading...

Loading...