5-2

EB|LTR|43_EN

May 2023 edition

Subject to technical changes

Installation

5.2 Preparing for assembly

Danger due to escaping medium resulting from unsuitable

fl ange seals!

Leaks caused by unsuitable fl ange seals can cause operating me-

dium to escape. Flange leaks can cause fatal injury to personnel

and damage the environment.

Ö The butterfl y valves of series LTR43-2 and LTR43-9.9 have

special dimensions, if applicable. It is indicated in the order

confi rmation or the dimension sheet if special dimensions are

required.

Ö Special dimensions can be requested from SAMSON

LEUSCH. Contact SAMSON LEUSCH through the nearest

SAMSON offi ce.

Danger of injury due to moving parts with spring-loaded

actuators!

Spring-loaded actuators may only be pressurised when installed

in the pipe and not to perform work on the butterfl y valve outside

of the pipe. There is risk of fatal injury if the pneumatic energy

suddenly fails and the valve disc moves automatically to the fail-

safe position by means of spring force.

Ö Install butterfl y valves that have a spring-loaded actuator with

the “fail open” fail-safe position in the open position. Remove

the pipe if necessary.

Ö Do not damage the sealing surface.

Employees or third parties may not be endangered.

Any applicable legal regulations of the country of destination

must also be observed.

Actuators of series LTR|43-2, LTR|43-4 and LTR|43-9 have an

interrupted fl ange sealing surface on one side.

For sealing surfaces according to EN1092-1B1 and B2 as well

as ASMEB16.5 RF and ASMEB16.47 RF, it must be ensured that

the fl at seals are suitable according to EN1514-1 and/or

ASMEB16.21.

Other seals.

For other seals, such as spiral or grooved gaskets, the standard-

ised dimensions may not be suitable.

Ö Contact SAMSON LEUSCH for suitable special dimensions.

Ö Upon request, SAMSON LEUSCH can supply these seals.

Damage to the butterfl y valve due to incorrect insulation!

Insulate butterfl y valves with a body extension with medium tem-

peratures below -60°C or above 350°C only up to the maxi-

mum permissible height.

Ö In the case of high temperature applications, insulate only the

lowest third of the insulation part.

Ö In the case of low temperature applications, insulate only the

lowest two thirds of the entire length.

Ö In the case of cold-box applications, insulate the cold-box

cover up to the lower edge. If the insulation part is insulated

at an impermissibly high level, it can lose its function!

DANGER

NOTE

The plant operator is responsible for cleaning the pipes in the

plant.

Ensure the following conditions prior to assembly:

− The actuator is clean.

− The actuator and all attachments inclusive of the pipes are

not damaged.

− The data on the type plate (type, nominal size, material,

nominal pressure and temperature range) matches the plant

conditions and conditions of use. For details about the type

plate, see Chapter “2 Markings on the device”.

− Additional optional components are installed or prepared to

the point as required prior to the assembly of the actuator,

see Chapter “3.2 Additional optional components on the

actuator”.

− Suffi cient installation space is available.

− The pipe connections must be aligned plane-parallel, fl ush

and tension-free.

− Measures for avoiding contact with hazardous media were

found.

− All welding requirements have been met.

Perform the following preparation steps for assembly:

− Get the material and tools ready that are required for

assembly.

− If the butterfl y valve and actuator are already assembled to-

gether, check the screw connections for the correct tightening

torques, see Chapter “15.1.1 Tightening torques” or

LW-

10017, Annex 15.2. Components can loosen up during

transport.

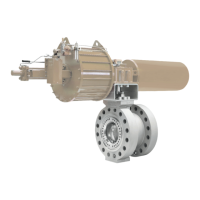

5.3 Assembling the butterfl y valve

The tasks are listed below that are necessary for assembly and

prior to the commissioning of the butterfl y valve.

Make sure before assembly that all necessary preparations are

made, see Chapter 5.2.

5.3.1 Assembling the butterfl y valve and

actuator

The SAMSON LEUSCH actuators are delivered in working order.

In individual cases, the actuator and butterfl y valve are delivered

separately and must be assembled.

The tasks are listed below that are necessary for assembly and

prior to the commissioning of the actuator.

Info

Loading...

Loading...