9-4

EB|LTR|43_EN

May 2023 edition

Subject to technical changes

Servicing

Ö Secure the actuator (500) with a crane, see the correspond-

ing actuator documentation.

Ö Mark the installation position of the actuator.

Ö Release only the screws (65) and wedge-lock-washers (67)

between the bracket (17) and the butterfl y valve.

Ö Lift the actuator with the crane and put it down in a safe

place.

Ö Disassemble the coupling (18) and secure the key(s) (68) in it

to prevent it from falling out.

Ö Remove the key(s) (64).

Ö Remove the nuts (56) and wedge-lock-washers (55) or spring

washers (59). When reassembling the spring washer set, ob-

serve the correct sequence and alignment.

Ö Release the screws (108) until the stuffi ng box can be pulled

off.

Ö Disassemble the gland (8) and remove the packing ring (39)

carefully with a suitable tool. (The support ring (239) remains

in the body.)

Ö Remove any residues in the packing area and clean it.

Ö Apply a thin layer of approved lubricant in the packing area,

see Chapter “15.1.2 Lubricants”

Damage to the butterfl y valve due to unsuitable lubricants!

The functionality of the butterfl y valve is ensured only by using a

certain lubricant. Unsuitable lubricants can corrode and damage

the surface.

Ö Only use lubricants recommended by SAMSON LEUSCH, see

Chapter “15.1.2 Lubricants”.

Ö In the case of increased requirements on the outer tightness

(TA-Luft), see Chapter “15.1.1 Tightening torques” or

LW-10007.

Ö Insert the new packing rings (39) one after the other. If avail-

able, it must be ensured that the trimmed edges are offset

with respect to each other.

Ö Assemble the gland (8), nuts (56) and wedge-lock-washers

(55) or spring washers (59).

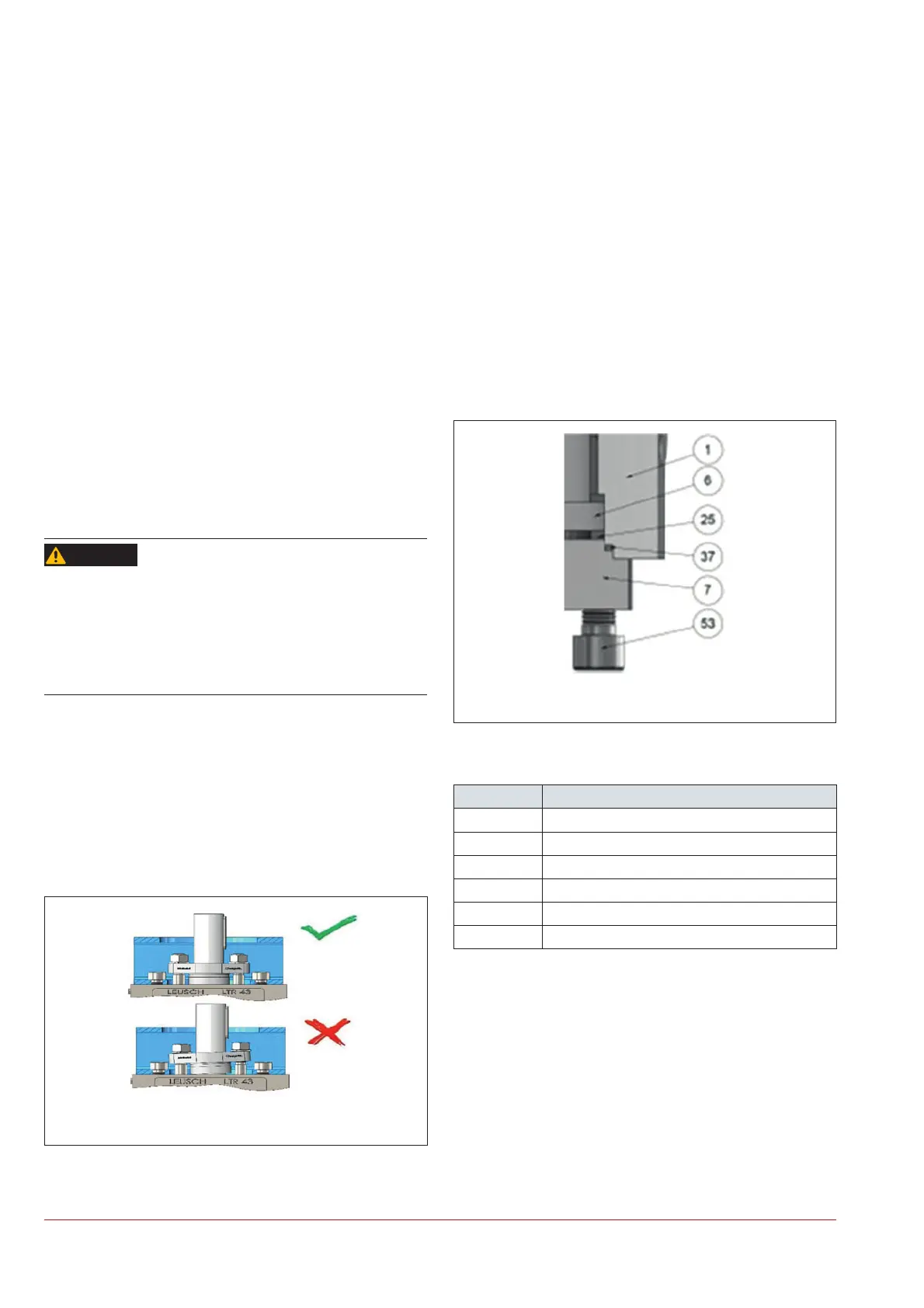

Figure|9-2: Correct tightening of the gland (8)

WARNING

Ö Tighten the nuts (56) alternately with slight manual force.

Make sure that the stuffi ng box does not tilt with respect to

the shaft.

Ö Assemble the key(s) (68).

Ö Tighten the nuts (56) in a criss-cross pattern with the specifi ed

torques, see Chapter 15.1.1 or

LW-10006 (STD) or

LW-10007 (TA-Luft).

Ö Assemble the actuator in the marked installation position.

Ö Check the tightness of the packing (39) and the functionality

of the actuator, see chapter “5.4 Checking the assembled ac-

tuator”. If the packing leaks, tighten the nuts (56) in a criss-

cross pattern in small steps. If there is still leakage, contact

SAMSON LEUSCH through the nearest SAMSON offi ce.

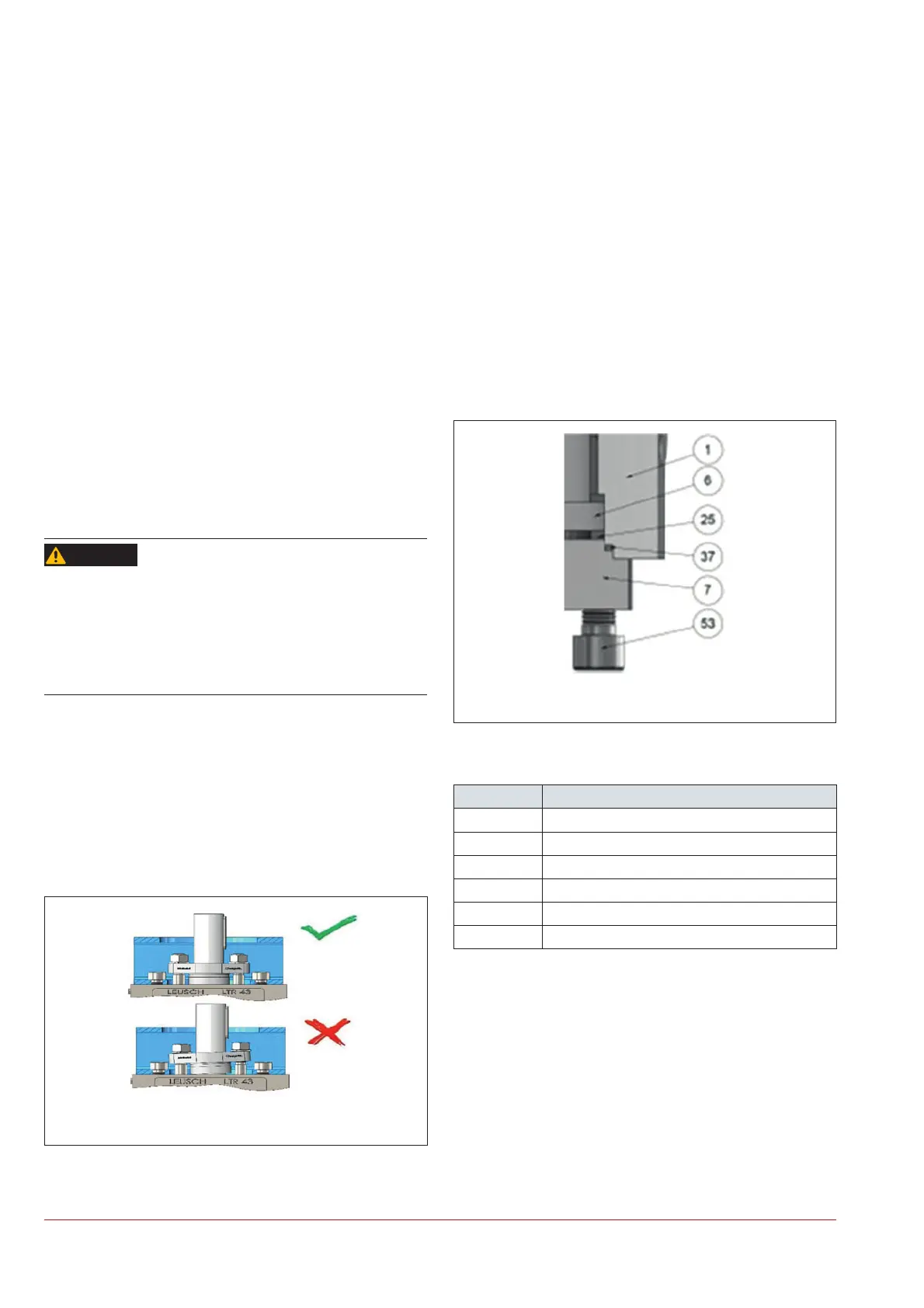

9.3.3.2 Replacing the gasket cover

Figure|9-3: Gasket cover replacement

Table|9-2: Parts list

Pos. Designation

1 Body

6 Shaft

7 Bonnet

25 Thrust ring

37 End cap seal

53 Screw

Ö Release and remove the screws (53), see Figure 9 3.

Ö Disassemble the bonnet (7) and remove the old cover sealing

(37). During disassembly, make sure that the thrust ring (25)

does not fall out.

Ö Remove the residues and check for damage.

Ö Apply a thin layer of approved lubricant on the new gasket

cover (37) and thrust ring (25) and position them on the bon-

net (7) and install.

Loading...

Loading...