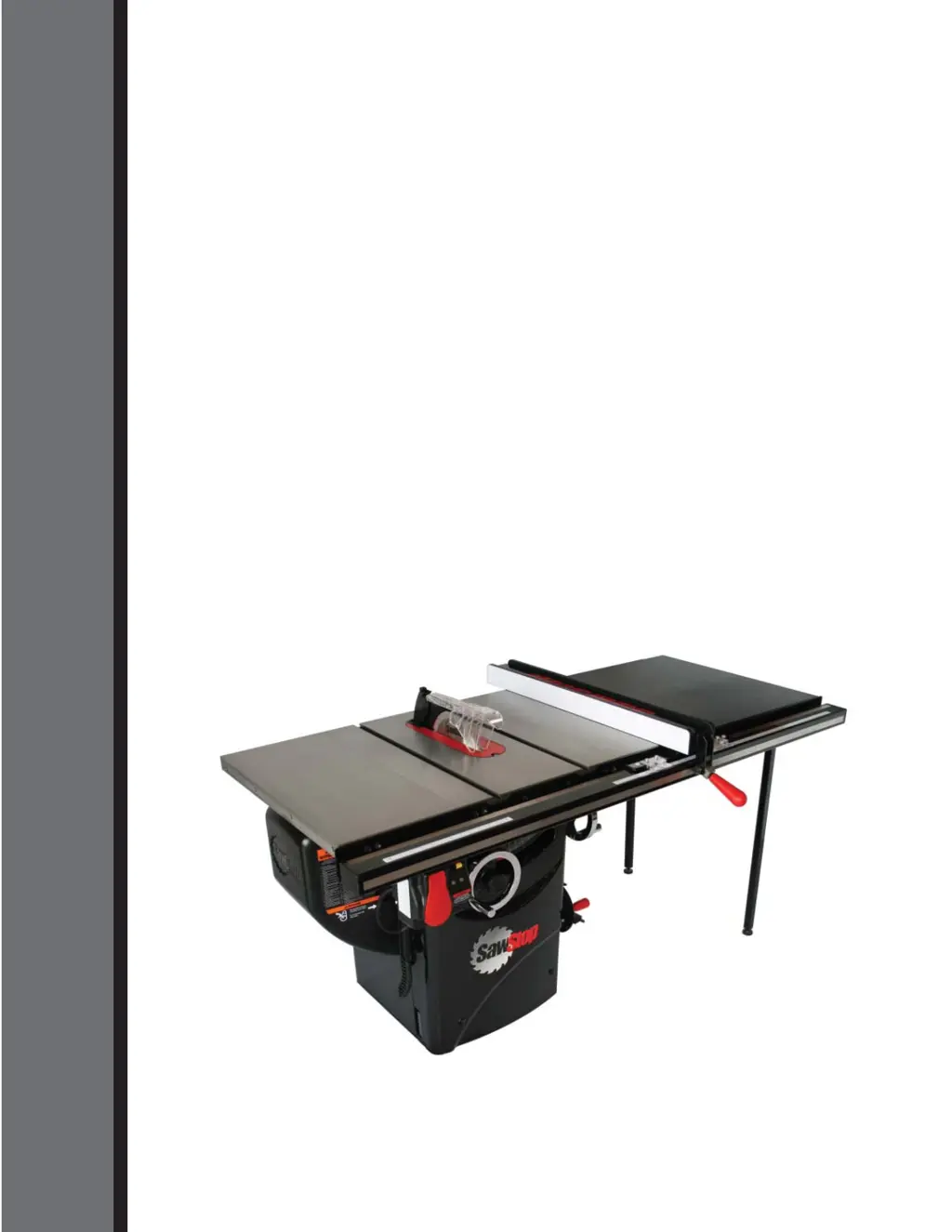

Why can't I remove the cartridge key from my SawStop PCS175 Saw?

- NNancy GarciaSep 8, 2025

If you cannot remove the cartridge key, ensure it is turned to the UNLOCKED position by turning the key clockwise until it stops. If it's still stuck, the shaft of the key might be binding; try turning and removing the key while pressing upward or downward on the key or cartridge.