Regularly check the electrical connection lines for dam-

ages. Please make sure that the connection lines are dis-

connected from the mains supply during the check.

Electrical connection lines must comply with the relevant

VDE and DIN regulations. Only use connection lines la-

belledwithH07RN.Thelabellingoftheconnectioncable

with the type specification is required.

AC motor Fig. 11

• Thesupplyvoltagemustbe230V/50Hz.

• Extensionlinesuptoalengthof25mmusthaveacross

section of 1.5 square millimetres. Extension lines with a

length of more than 25 m must have a minimum cross

section of 2.5 square millimetres.

• Themainsconnectionisprotectedwithadelay-action

fuse of 16 A.

Rotary current motor, Fig. 12

• Thepowersupplymustbe400Volt/50Hz.

• Theelectricalconnectionandextensioncordsmusthave

vewires=3P+N+SL.

• Extensioncordsupto25metresinlengthmusthavea

cross section of 1.5 square millimetres; those over 25

metres must have a cross section of at least 2.5 square

millimetres.

• Theelectricalconnectionissecuredwitha16Afuse.

• Beforetherstconnection,orwhenthesiteischanged,

the direction of rotation should be checked and, if nec-

essary, the polarities switched round.

If you have further questions, please specify the follow-

ing:

• Motormanufacturer

• Kindofcurrentofthemotor

• Datafromthemachinetypeplate

• Datafromtheswitchtypeplate

If you return the motor, always return the complete drive

unit with the switch.

Maintenance

Perform resetting, measuring, and cleaning work exclusive-

ly when the motor is turned off. Disconnect the mains plug,

and wait until the rotating tool stands still.

All protection and safety devices must be immediately re-

installed once the repair and maintenance work is com-

pleted.

The built-in ball bearings are maintenance-free.

Recommendations:

• Slightlyre-lubricatetheslewingsegmentsofthetable

and the bend tensioning device.

• Regularlycleanthesawband.Woodleavesresinsedi-

ments. We recommend the deresinifying concentrate

PharmolHEK,itemno.61009700forthecleaning.

• Regularlychecktheguidingrollersandthecounterpres-

sure bearings. If required, readjust or disassemble them,

and grease or exchange the parts.

• Exchangeworn-outtableinserts.

• Ensurethatthetabletopisalwaysfreeofresin.

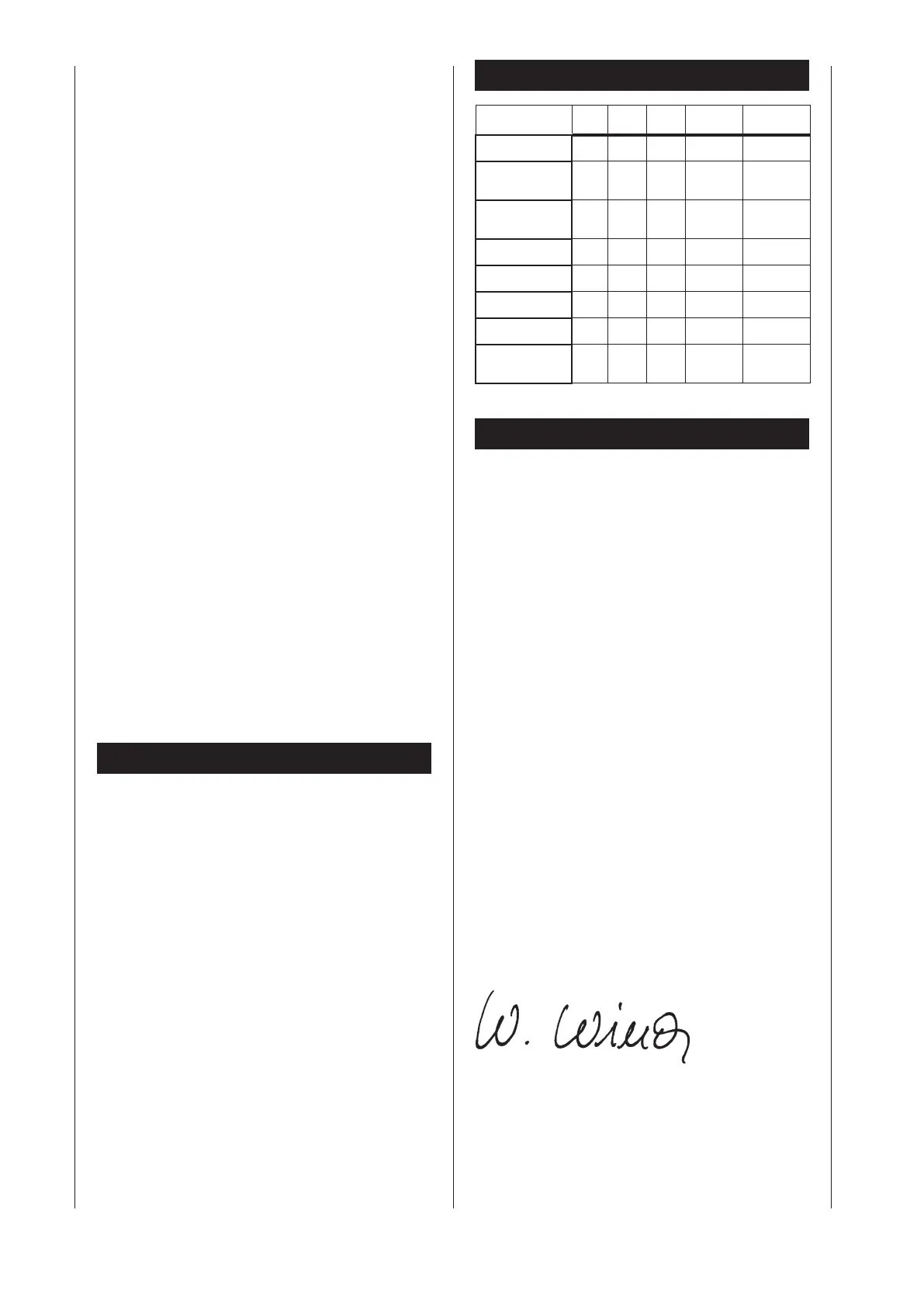

Special Accessories

Article/

Application

Width Size Length Tooth /Inch Art.No.

sawband/

standard

12 0,65 2895 4

73230701

sawband/

curving, sweep&

fret cut

6 0,65 2895 6

73230702

sawband/

for non-ferrous

metals

6 0,65 2895 10

73230703

sawband/

cut on edge, upright

15 0,65 2895 4

73230704

sawband/

fine-cut

12 0,65 2895 10

73230705

sawband/

wood and metal

20 0,60 2895 4

73230707

sawband/

cut on edge, upright

30 0,60 2895 4

73230708

sawband/

for non-ferrous

metals

6 0,65 2895 24

73230709

EC Declaration of Conformity

We, Scheppach Fabrikation von Holzbearbeitungsmaschinen GmbH,

Günzburger Str. 69, D-89335 Ichenhausen hereby declare that the ma-

chine named below correspondends to the relevant safety and health

requirements of the EC guidelines specified below in its design and

construction and in the version which we introduced to the market.

This declaration becomes invalid if changes are made to the machine

without our consent.

Machine description:

Band saw

Machine model:

Basato 4

RelevantECdirectives:

EC machine directive 98/37/EG (< 28.12.2009), EC machine directive

2006/42/EG (> 29.12.2009), EC Low voltage directive 2006/95/EWG,

EC-EMV directive 2004/108/EWG.

Applied harmonized European Standards:

EN292-1, EN292-2, EN294, EN349, EN418, EN847-1, EN954-1, EN1088,

EN50082-1, EN60204-1, EN101014, EN60555-2, EN60555-3, EN61029-

1, EN61029-2-5

Applied national technical standards and specifications, especially:

ISO 7960

NotiedbodywithinthemeaningofAnnexVII

Prüf- und Zertifizierungsstelle

Fachausschuss Holz

Vollmoellerstraße 11

70563 Stuttgart-Vaihingen

Engaged for

EG-Baumusterbescheinigung, Staubprüfung

Date

Ichenhausen, 01.03.2007

Signature:

on behalf of Wolfgang Windrich

(Technical manager)

Loading...

Loading...