5 Commisioning

Operating Manual 90° ACTUSAFE CMF(S)QT

OM-ENGLISH-Failsafe-QT-16xx-V2.00-2022.03.01

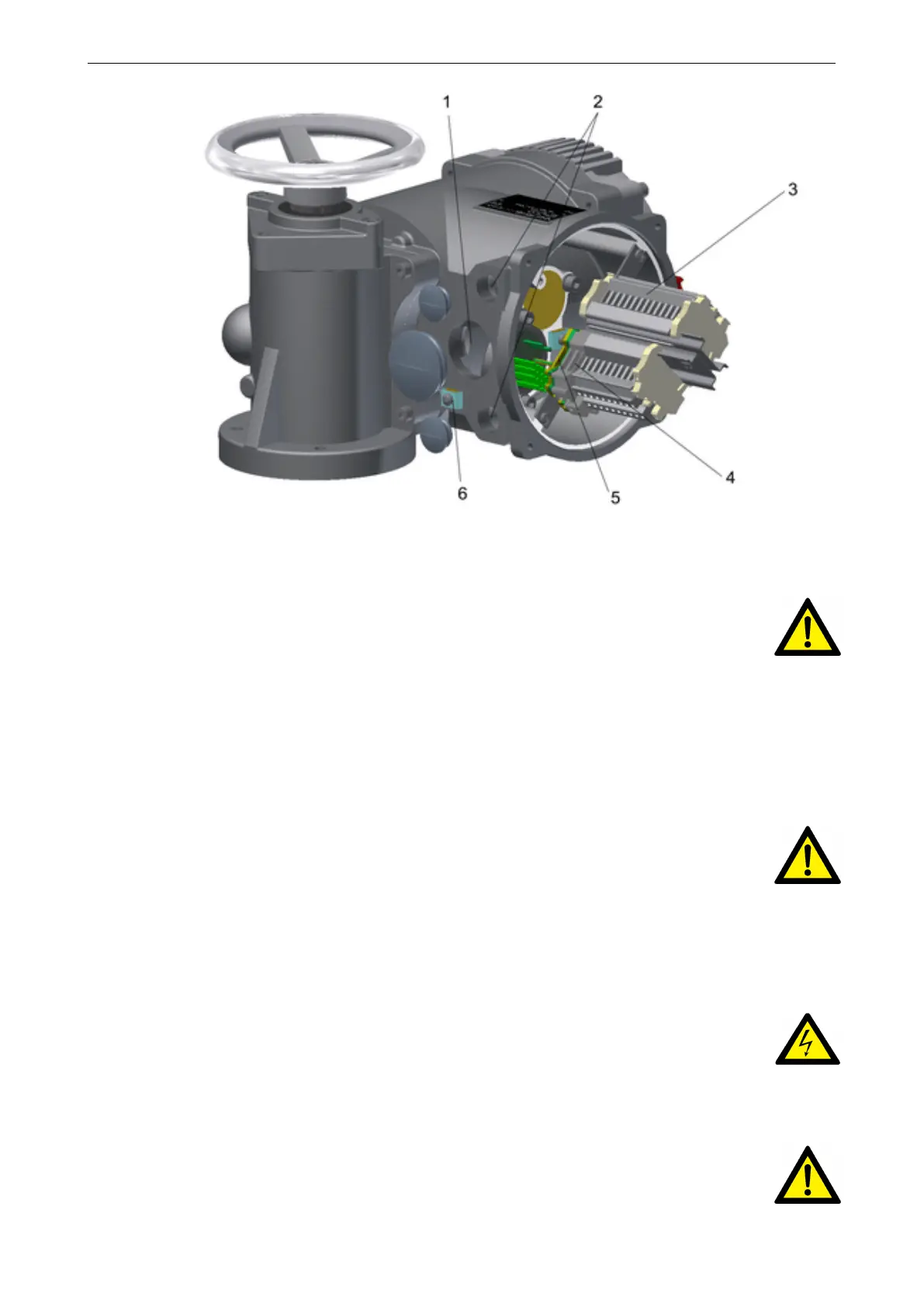

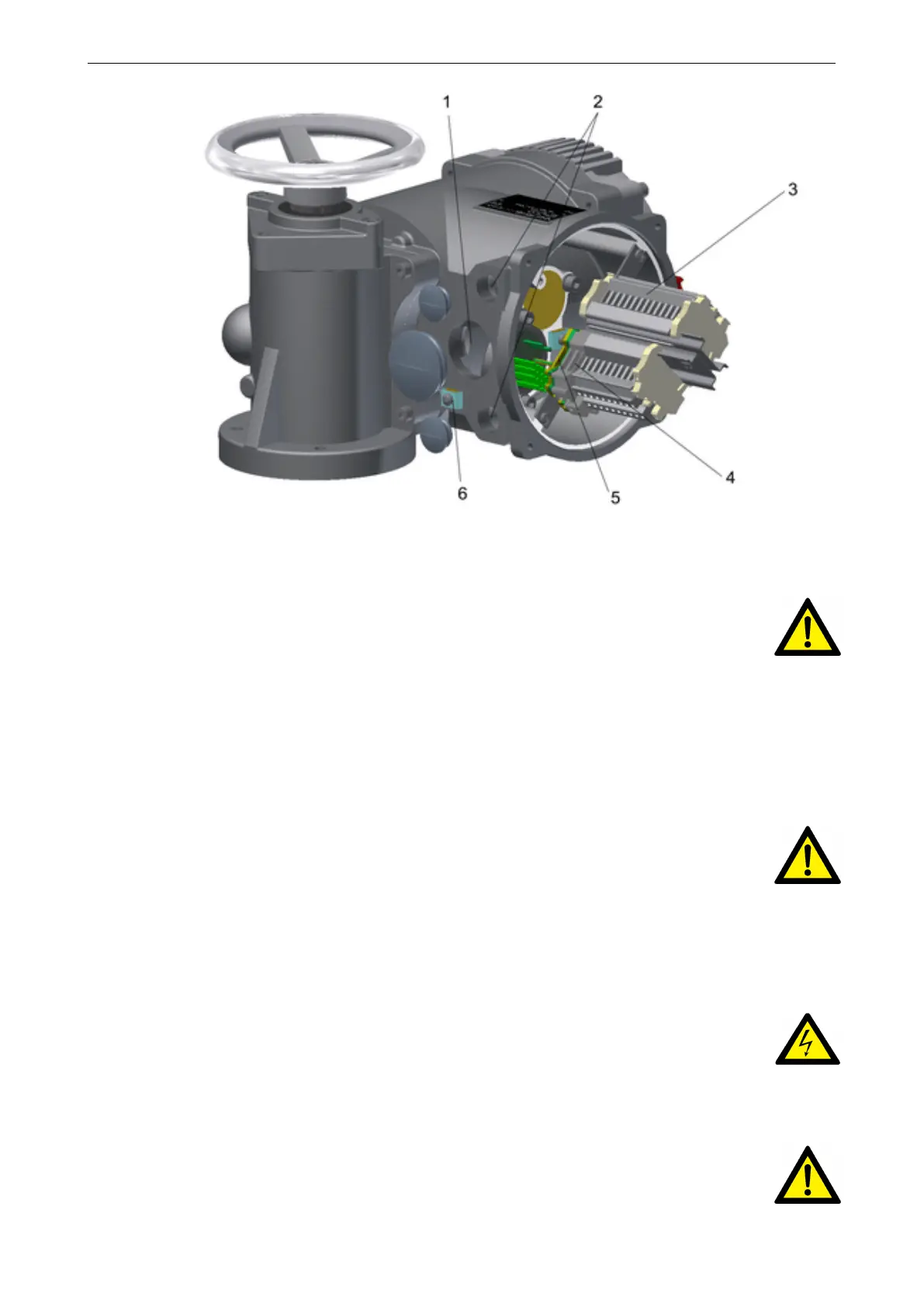

Figure 24: Terminal box: 1. . . Metric screw M40x1,5, 2. . . 2 pcs. M20x1,5, 3. . . Terminals for the control signals,

4. . . Terminals for the power supply, 5. . . Terminal for ground connection, 6. . . Outside ground connection

CAUTION: If, during outdoor installation, commissioning is not carried out immediately after electrical connec-

tion, the power supply must be connected at a minimum to achieve a heating effect. In this case, the silica gel

may remain in the connection compartment until commissioning. See section 3.3, page 26.

5 Commisioning

Before commissioning, ensure that the actuator is correctly assembled and electrically connected (see section 4, page 27).

NOTE: Remove silica gel from the connection compartment.

5.1 General

CAUTION: During commissioning and after every disassembly of the actuator, the electric end positions (see

section 5.5, page 31) must be reset.

5.2 Manual operation

The use of a differential gearbox in the handwheel assembly makes mechanical switching unnecessary during manual

operation.

CAUTION: Manual operation with mechanical or electromechanical equipment (such as: lever, drilling machine,

etc.) is NOT ALLOWED, as this may damage the product.

5.3 Mechanical default settings, preparation

The use of multi-turn sensors makes mechanical settings unnecessary.

CAUTION: Before the motorised operation of the valve, it is essential to check and eventually adjust torque

settings.

32

Loading...

Loading...