Operation

30

7/27/12

Operation Manual - SP 305

back to reverse and relieve the pressure in the line.

See the information in this manual about removing

plugs from lines starting on page 34.

• Once the concrete comes out at the discharge point,

move yourself into position to see the discharge.

Remember, you must also be able to see the pump,

so arrange for a spotter if you cannot. In some

circumstances, it is allowed to have the ready mix

driver monitor the pump end of the job. If you will

be allowing it, you MUST be sure that the ready

mix driver understands how to stop the pump and

what will happen if air is allowed into the delivery

line. The ready mix driver may refuse the

responsibility of watching the pump. If this

happens, you will still need to arrange for a spotter.

Because of the risk of injury to the ready mix

driver and the placing crew if air is introduced into

the delivery system, the hopper level must be

monitored at all times. If the ready mix driver will

not do it, you must still arrange that it be done

(Figure 20).

• Adjust the volume control knob as needed for

faster or slower pumping.

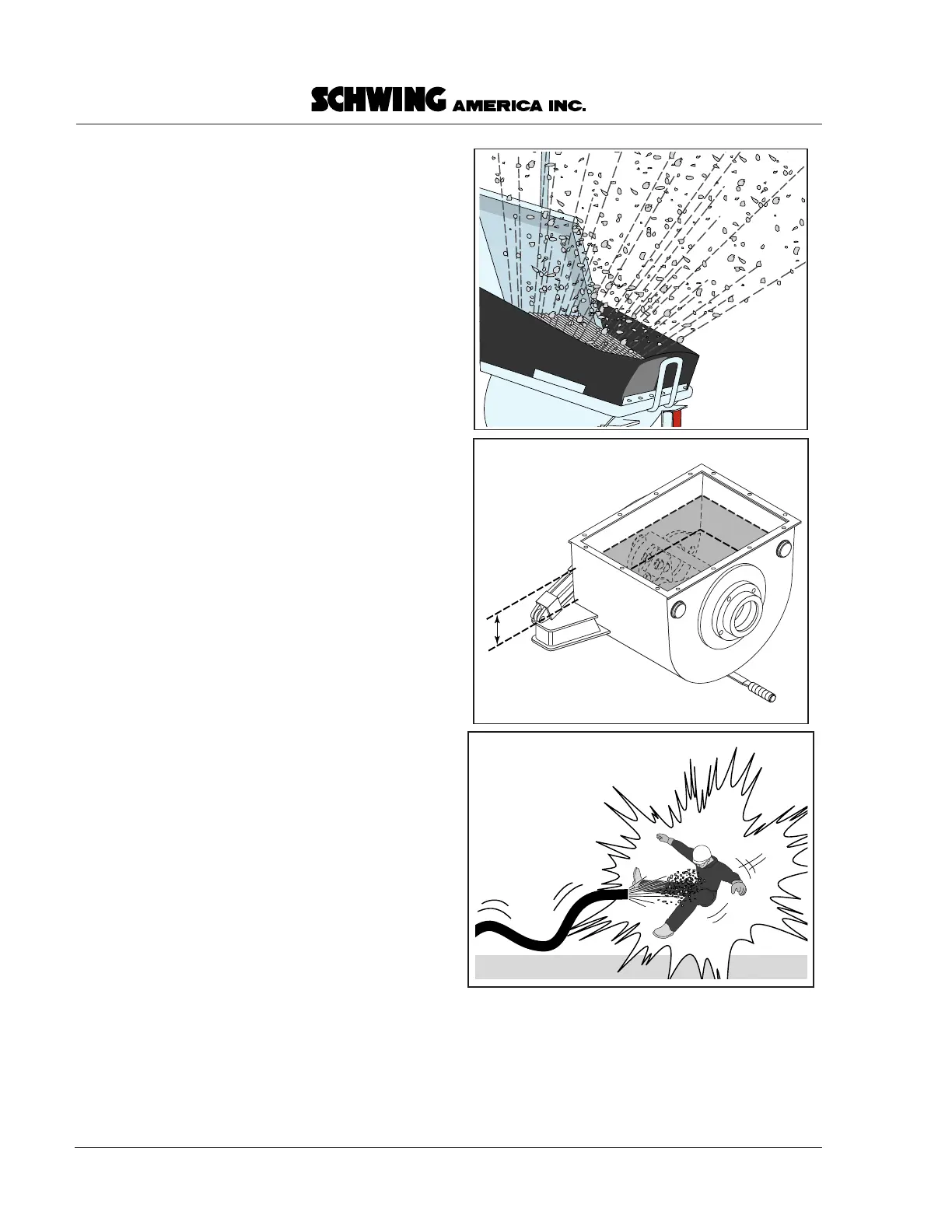

• Watch the hose handler closely. Be ready to stop

the pump when required. Kinking a placing hose

while pumping can be dangerous, because it causes

the pump to go to maximum pressure, simulating a

blockage. If you see that the placing crew is

kinking the hose, stop pumping and talk to them

about it.

• Keep an eye on the pump. Listen for engine

bogging (a sign of plugging). Watch that no one,

especially children, get near the unit.

• When the ready-mix truck is empty, the driver

should signal you by voice or horn. If you have

shown the driver how to stop the pump, you could

also be signaled that way. In addition, an

experienced pump operator will be able to tell by

the sound of the rotating drum that it is almost

empty. The remaining larger aggregate in an

almost-empty drum falls from the fins, and instead

of hitting on concrete, it hits on steel, making a

distinctive sound. Be aware to listen for these

clues, so that you can stop the pump with a full

hopper. (You will need a full hopper so that you

can keep the concrete moving if you have to wait

for the next load.) If no more concrete will be

coming, such as at the end of the pour, try to end

up with only about a third of a hopperful.

WARNING!

You cannot completely empty the

hopper, because air will be drawn into the concrete

airhop1.eps

Figure 20

Do not allow air to enter the

pumping cylinders. Keep the

hopper full when pumping.

minimum 4 inches above

material cylinder opening

Svlvminlev.eps

Loading...

Loading...