Appendix

Operation Manual -

SP 30572

revDate

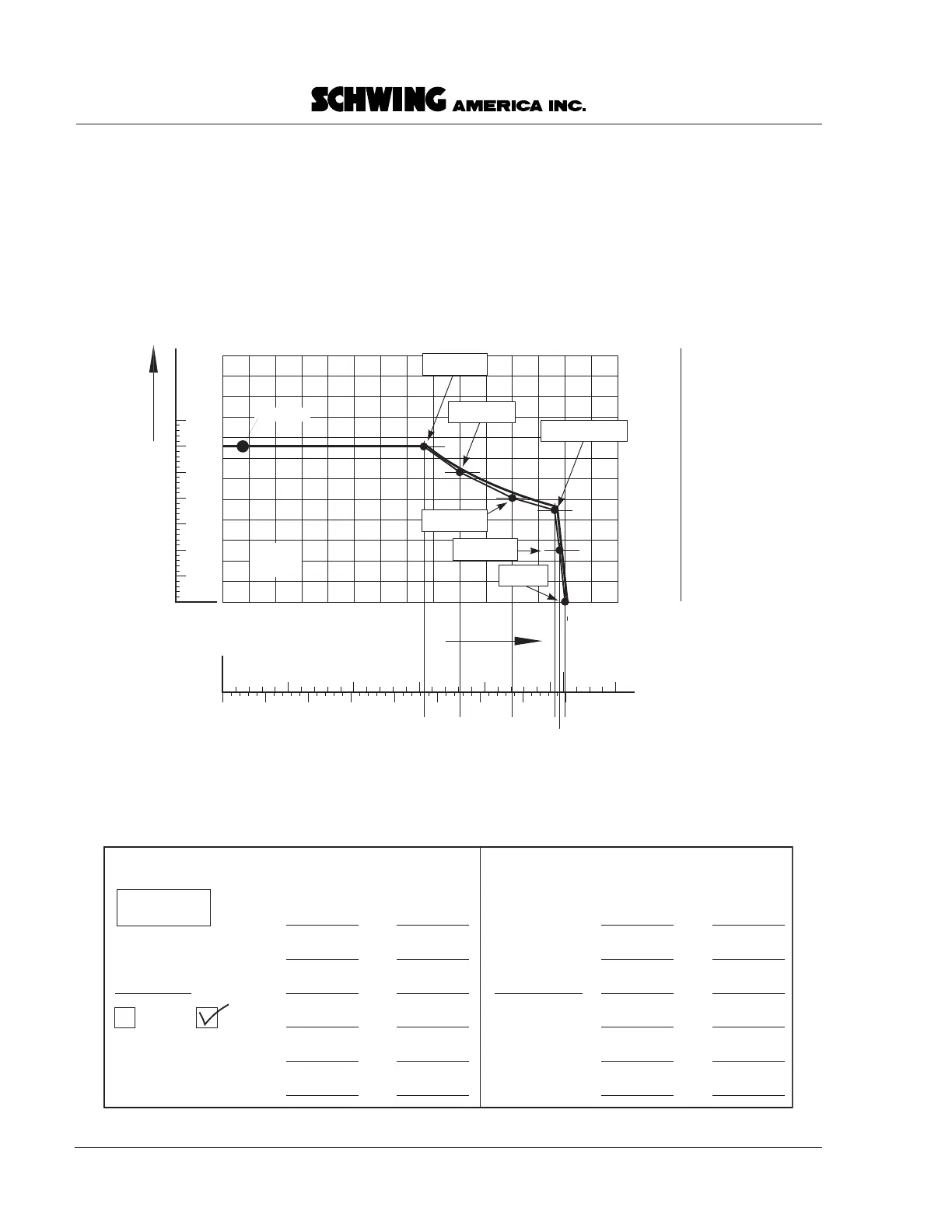

• Connect the dots. If your plotted line reason-

ably matches the specification plot on the

chart, the pump is fine. If your line is to the

lower left of the specification plot, the pump is

getting weak. If your line is to the upper right,

you have done the test incorrectly, or you are

using the wrong chart. In our example, the

pump is okay. (See the plot that follows.)

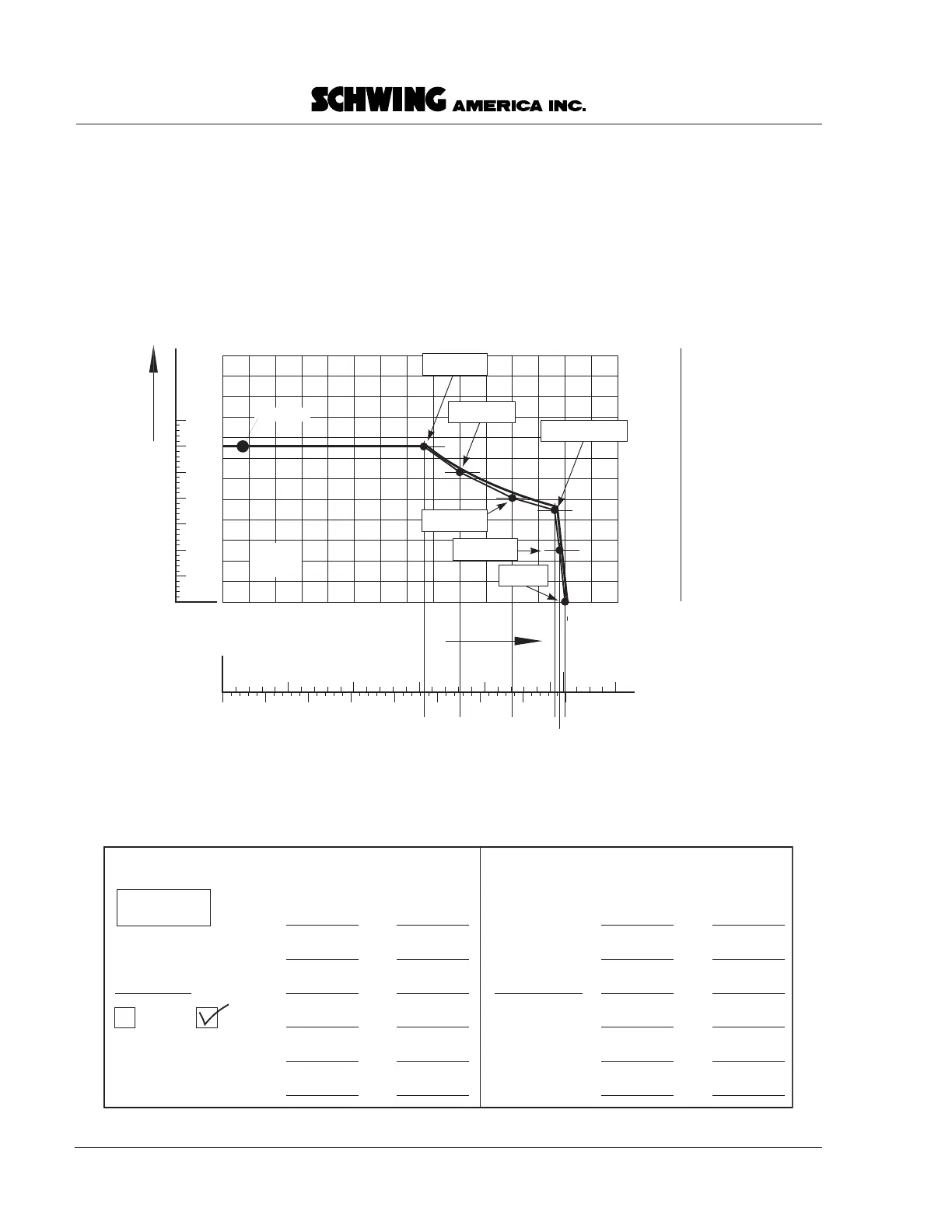

Check the second pump. Hook up the flowmeter just as

when you checked the first pump. Again, be sure that

you have the correct speed, gear, chart, and so on. This

time our example will have worse results.

13

CONCRETE OUTPUT (cu yd / h)

NUMBER OF STROKES

(stroke / min.)

OIL VOLUME

(liter / min.)

26 39 52 65 78 92 105 118 131 1440 157 170 183

ROD SIDE

ROD

SIDE

350

100 200 300 40050 150 250

51015202530

ROD SIDE

(bar)

CONCRETE

PRESSURE

(BAR)

7

14

21

28

34

41

48

55

62

70

76

83

CONCRETE

PRESSURE

(PSI)

100

200

300

400

500

600

700

800

900

1000

1100

1200

52758

50

100

150

200

250

300

350

OIL PRESSURE (BAR)

196

170.5

26

Breakpoint

breakpoint

178 bar

250 bar

300 bar

0 bar

100 bar

200 bar

(234) (276) (338) (388)

(392)

(398)

OK

Piston side scales have been removed for clarity

000317.eps

Liters/min

(read on meter)

Tota l

(for plotting)

0 bar

100 bar

breakpoint

150 or 200 bar

250 bar

300 bar

x 2

x 2

x 2

x 2

x 2

x 2

Liters/min

(read on meter)

Tota l

(for plotting)

x 2

x 2

x 2

x 2

x 2

x 2

1st Pump 2nd Pump

Breakpoint

specification

breakpoint

199

196

194

169

138

117

178

398

392

388

338

276

234

178

195

183

166

137

102

69

178

390

366

332

274

204

138

000030.eps

Loading...

Loading...