STEP 1 (Note: On swing gates with two leaves the limit switches have not to be bridged)

Make all the electrical connections and jumpers on all the unused N.C. contacts (photocells, limit switches,

etc).

If a geared motor equipped with a mechanical or hydraulic anti-crush safety device is being used, set the

operating torque (trimmer Rv1) to the maximum value and then adjust the motor torque using the special by-

pass valves or clutch adjustment screws located on the actuators.

If a motor without a mechanical or hydraulic anti-crush safety system is being used, set the operating torque

to the maximum value ONLY for the self-learning process. Immediately afterwards, set a torque value that

will ensure anti-crush safety, in accordance with current legislation.

ATTENTION!

THIS PROCEDURE IS POTENTIALLY DANGEROUS AND MUST BE CARRIED OUT ONLY BY

SPECIALIZED PERSONNEL, ADOPTING ALL SAFETY PRECAUTIONS.

STEP 2

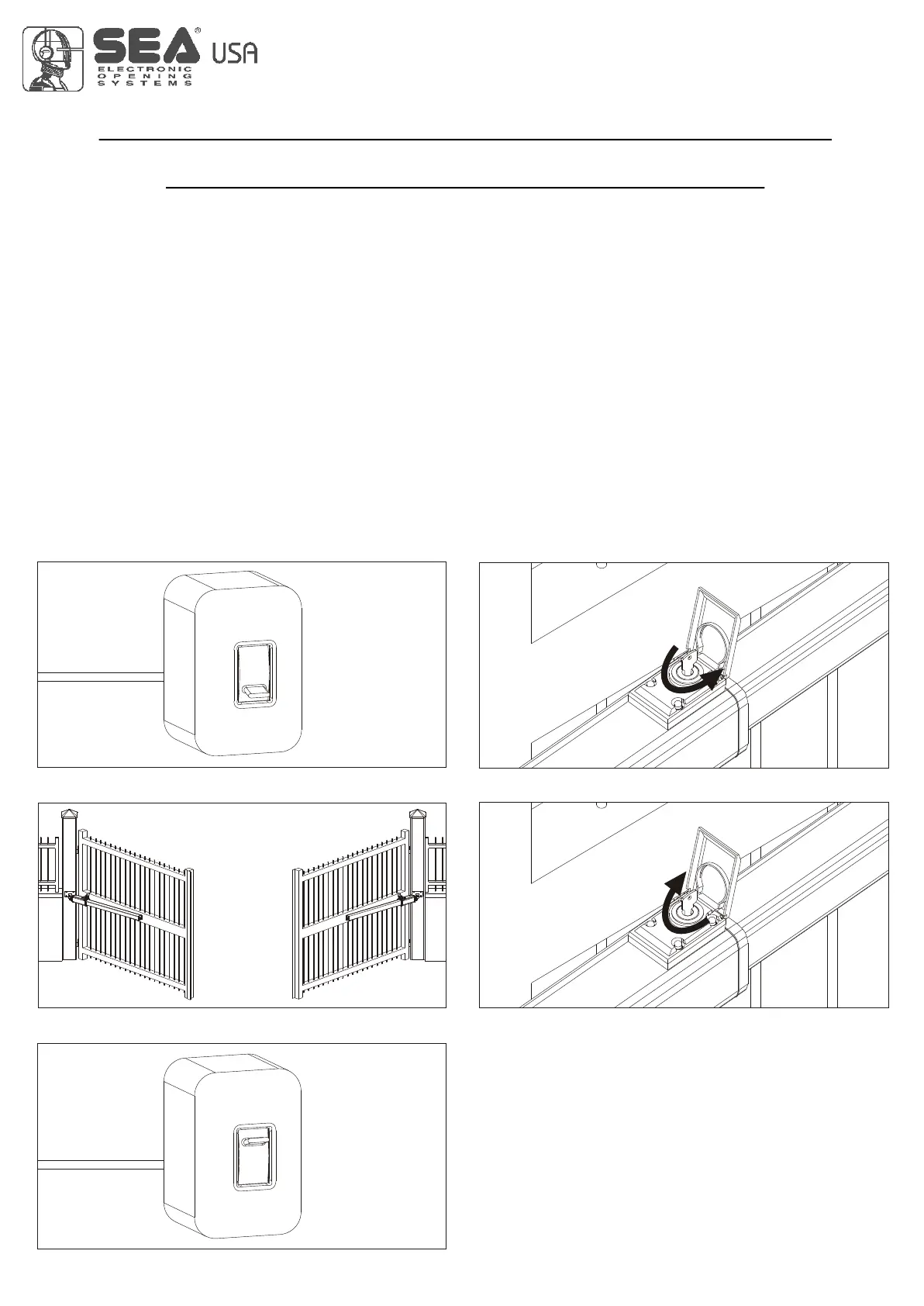

Disconnect the power supply (Fig. 1), release the gate operator (Fig. 2) and stop the leaves in the half-open

position (Fig. 3). Lock the motor (Fig. 4) and turn ON the power (Fig. 5).

Fig. 2

Unlock

Fig. 1

Fig. 3

M1

Fig. 4

M2

F

F

O

Fig. 5

N

O

2

1

GATE 2

SELF-LEARNING OF OPERATING TIMES

FOR SWING GATES OPERATORS

17

Lock

Example

Example

International registered trademark n. 2.777.971

Notice: Encoder activation

With the safety gate (encoder 1 and encoder

2) on both motors put dip 8 on ON before

programming.

To exclude its function put dip 8 on OFF

avoiding to repeat the selflearning

procedure.

REV 05 - 10/2010

Loading...

Loading...