© Sensorlink Swarm AS 2021

− Torque wrench for tightening the steel band buckle up to 4 Nm

− 5mm hex torque wrench bit

− Ruler or tape measure to measure installation bend length

6.2.3 Pipe preparation

Prior to installation of the Swarm S2 LT Sensors, the pipe surface should be prepared through the following steps (for

installation of up to four sensors on one band). Please note that the four sensors many also be installed on individual

bands if monitoring requirements requires that:

1. If the pipe is insulated, about 150mm of the insulation in the flow direction should be removed from the

whole circumference of the pipe. No residual should be left on the pipe.

2. The desired installation point for each sensor should be identified.

3. If the sensors are to be installed on a weld between two pipe sections, the weld cap should be grinded

flush to the pipe outer wall at each sensor installation location.

4. An area of roughly 20mm diameter should be cleaned and smoothened at each sensor installation

location. Note that the goal here is to get a smooth surface and NOT to flattening the pipe. Therefore,

excessive material removal should be avoided.

6.2.4 Swarm S2 LT Sensor mechanical installation

Follow the steps in Table 5 to install a single band with up to 4 Swarm S2 LT Sensors on the pipe.

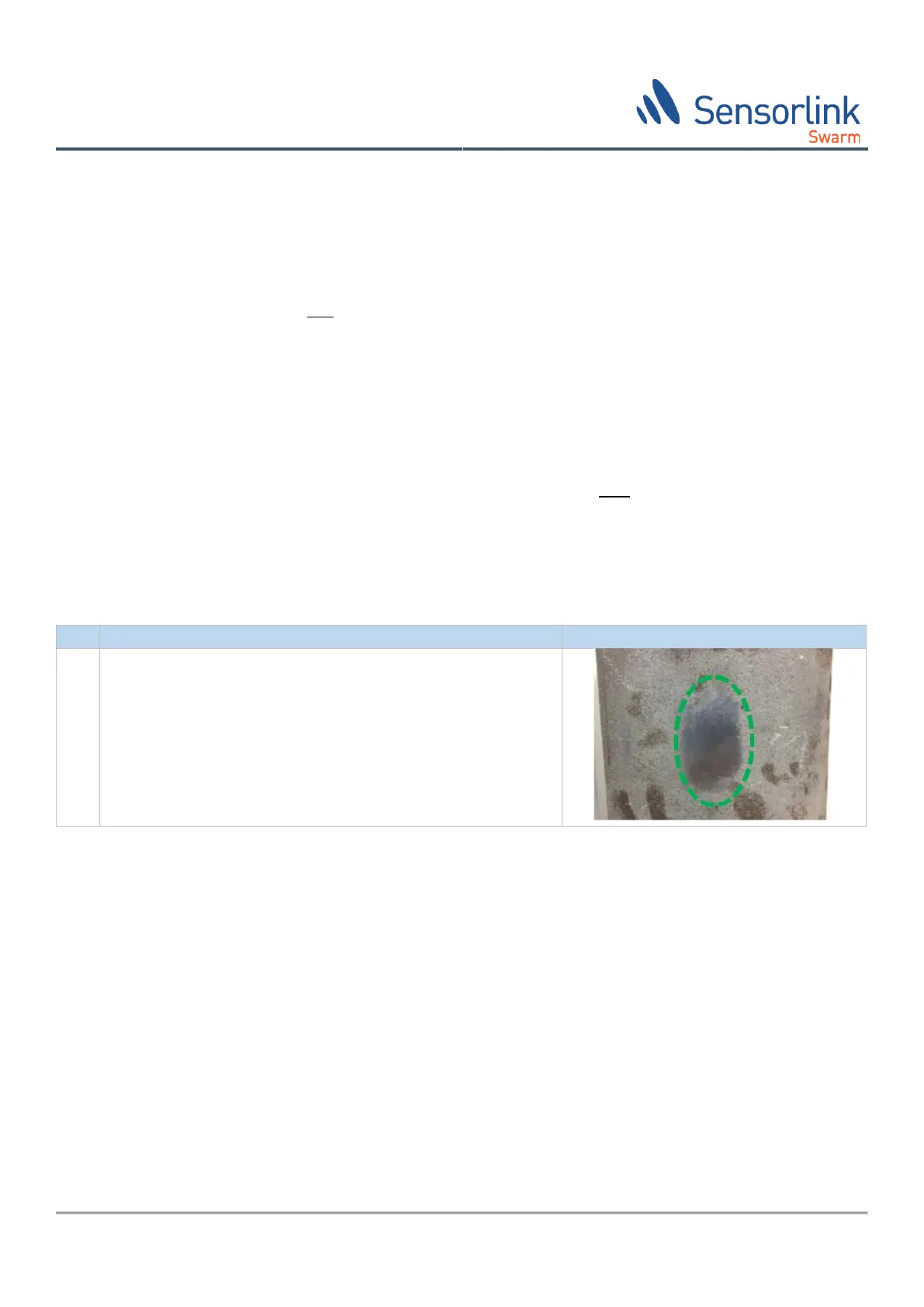

Identify the Thickness Monitoring Location (TML) where you

intend to install the sensors. Evaluate the surface and attempt to

measure the wall thickness with an UT instrument. Clean and

polish the area of the TML with a sandpaper to a smooth and

preferably shiny surface.

Loading...

Loading...