34

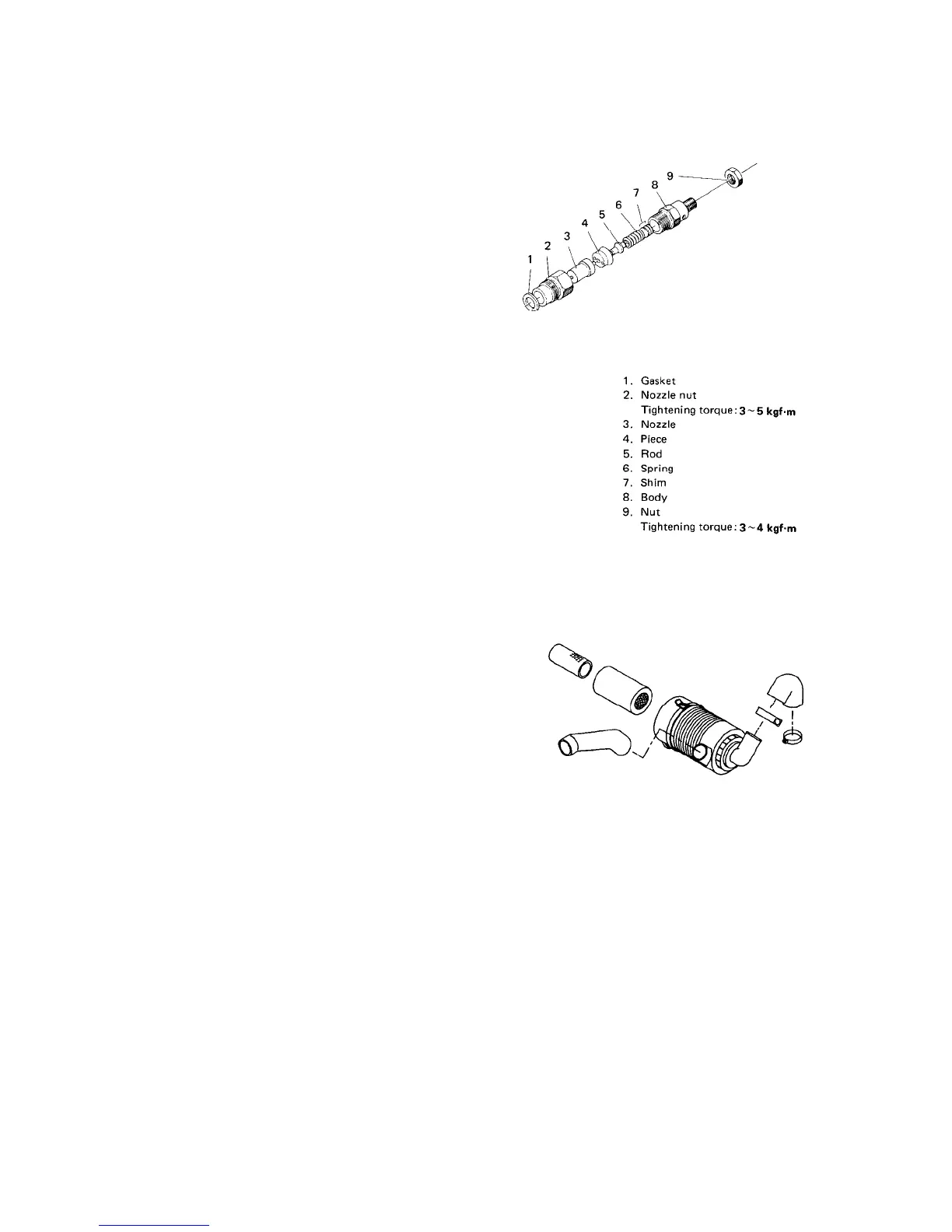

Reassembly and adjustment

(1) When assembling a new nozzle ass’y, heat light oil to

50 – 60°C and remove the rust preventive oil in it.

Slide the body and needle valve to ensure that they

slide lightly.

(2) Invert the body, place the shim, spring, rod, piece and

nozzle on it in this order, cover the nozzle nut and

tighten.

(3) After assembly, check for the nozzle injection

pressure.

a. Adjust by the adjusting washer (shim) so that the

injection is started at 11.76 MPa {120 kgf/cm

2

}

on Model J843 and 14.7 Mpa {150 kgf/cm

2

}

on Model N843L using a nozzle tester.

b. The pressure increases or decreases about 0.98

MPa {10 kgf/cm

2

} by a washer of 0.1 mm.

(4) Injection condition

a. Small drops should not be mixed in the spray.

b. The oil should be injected describing a cone by

straight lines toward the center line of the

nozzle.

c. Place white paper at about 30 cm from the

nozzle and confirm that the spray is

approximately circular when injected.

d. Keep the oil pressure lower by 1.96 MPa {20

kgf/cm

2

} than the specified value 11.76 MPa

{120 kgf/cm

2

} on Model J843 and 14.7 Mpa

{150 kgf/cm

2

} on Model N843L and check that

the test oil does not drop form the nozzle end.

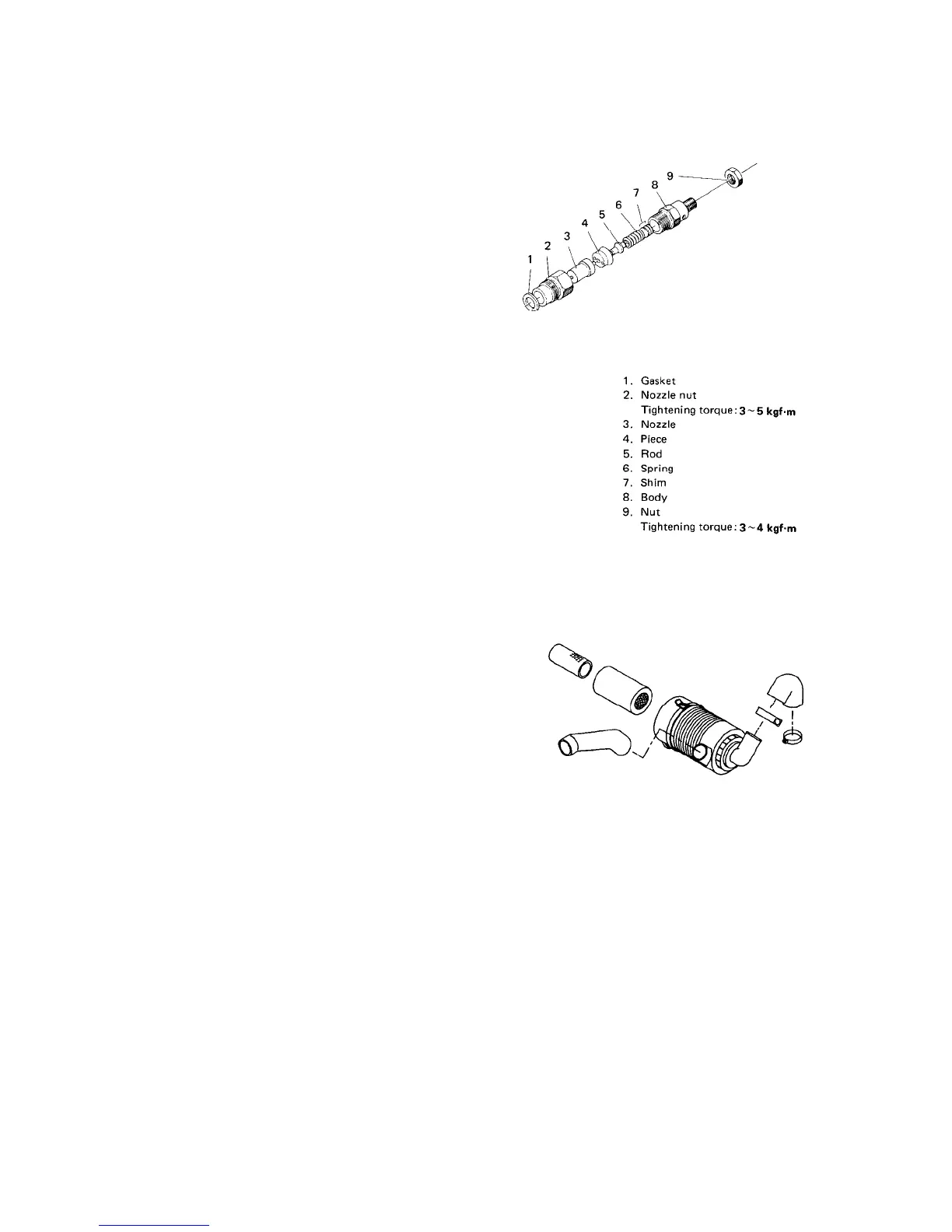

22) Air Cleaner

Structure and functions

(1) The air cleaner is connected to the cylinder with the

air cleaner hose.

(2) The air cleaner is of the cyclone type incorporating

filter element and removes dust from the intake air.

055X

035X

Inspection and replacement

(1) Take out the element every 100 – 200 hours and blow compressed air (less than 7kgf/cm

2

) from the inside and clean.

(Clean the dust deposit on the dust pan also.)

(2) If soot or oil has sticked to the element, immerse it in neutral detergent for about 15 minutes and then wash by shaking

several times. Rinse in clean water sufficiently and dry naturally.

(3) When the air cleaner is used in dust place, clean it earlier.

(4) After cleaning 6 times or once every year, replace the element with new one.

(5) After completion of cleaning, apply light from the inside of the element. It should be replaced with new one if

puncture, pin hole, and especially thinner part is observed or if the gasket is broken.

(6) Do not use the element before drying completely.

Loading...

Loading...