72

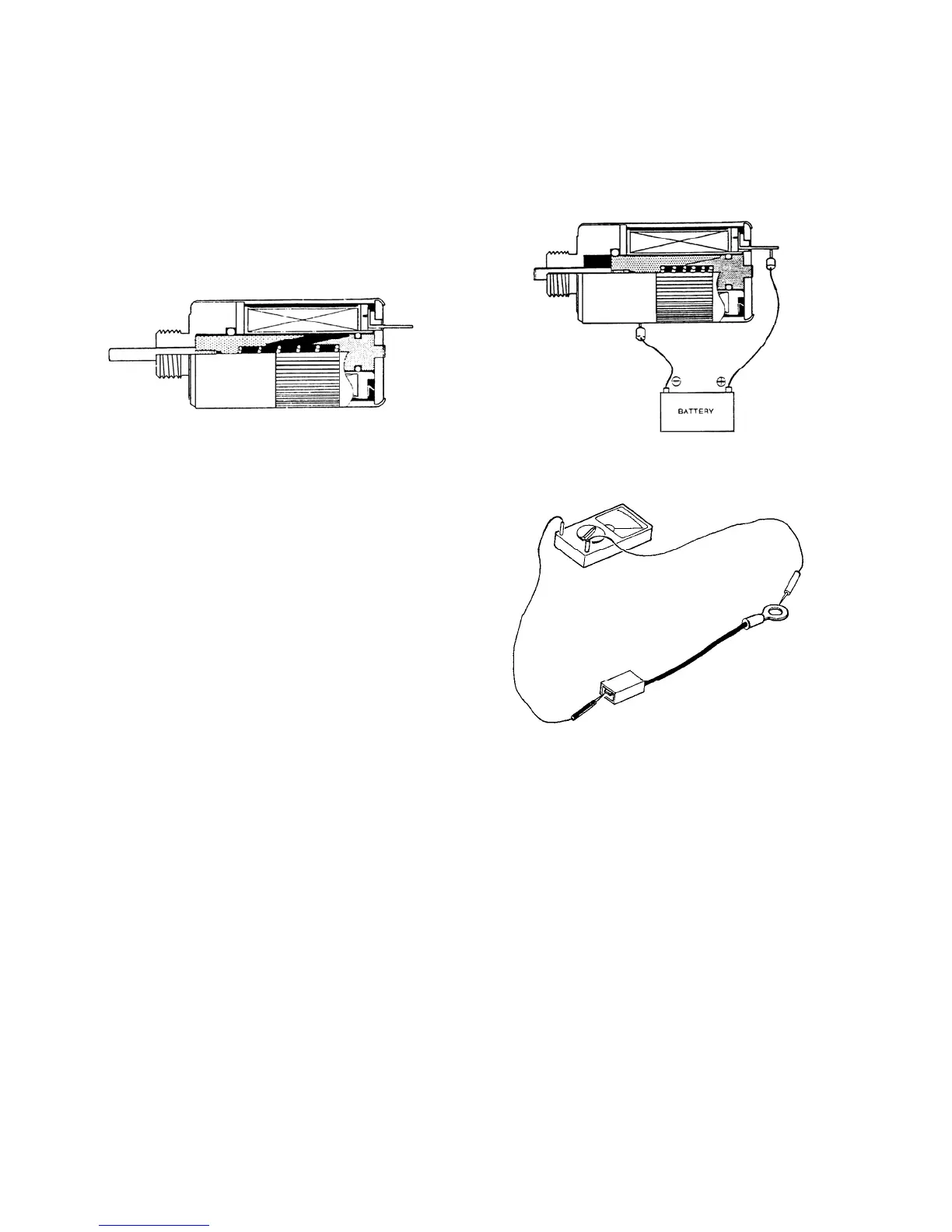

7. Engine Stop Solenoid

Inspection

Connect (+) side of the battery to the terminal of the

engine stop solenoid and (-) side to the main body. If the

plunger is sucked into the main body, the engine stop

solenoid is normal.

134X

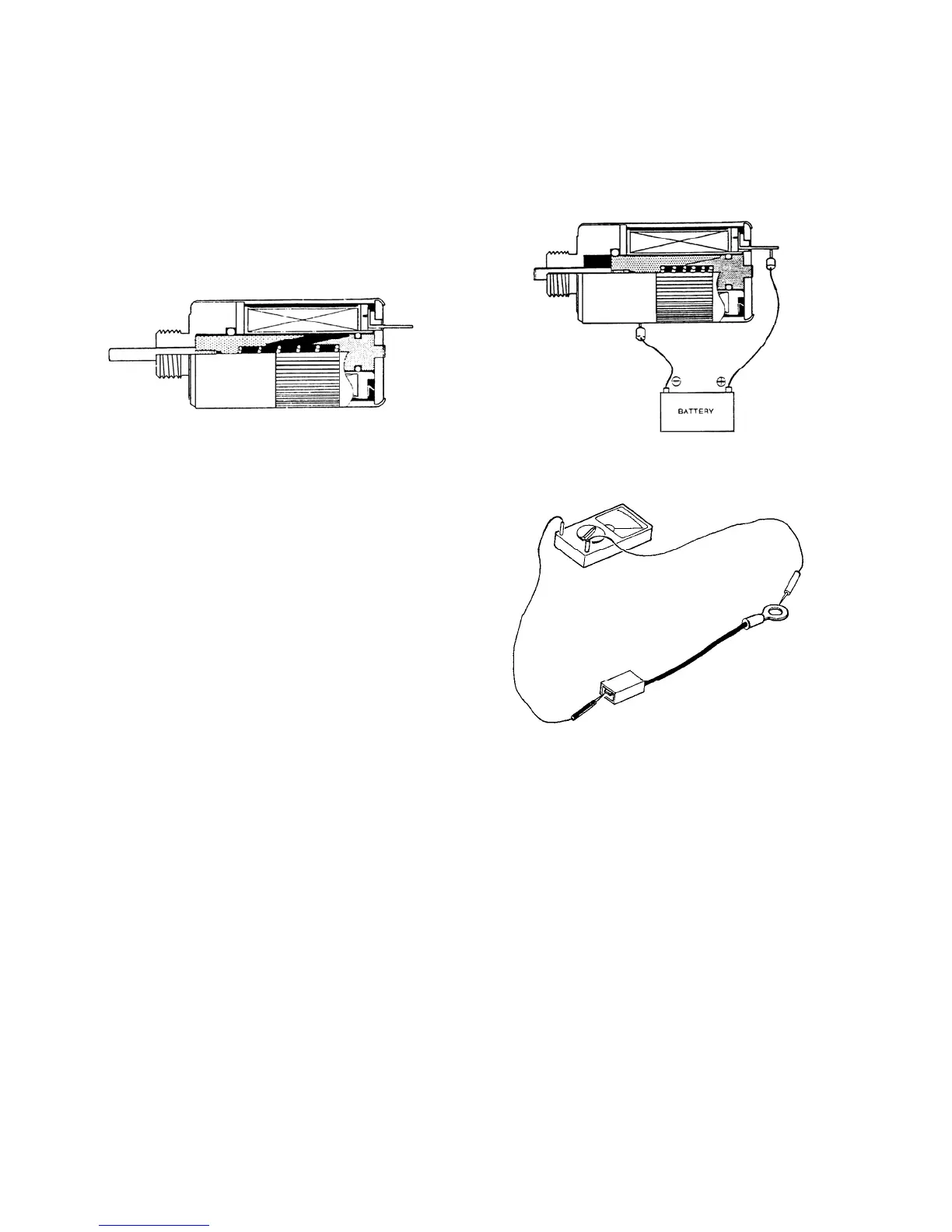

8. Fusible Link

Inspection

The fusible link is installed between the battery and fuse

box to protect such parts that could not be protected by

fuses or a circuit (starter circuit) to which large current

flows instantaneously. Check the continuity with a circuit

tester.

NOTE:

1. If a fusible link is burnt out again immediately

after it is replaced, short circuit of the wiring can

be considered as the reason. Check the wiring

harness in such a case.

2. Never use a substitute wire or the like when the

fusible link is burnt out.

135X

136X

9. Wiring Harness

Inspection and service

(1) Disconnect the negative cord of the battery when inspecting or servicing the wiring harness.

(2) Check each wiring for damage of sheathing due to wiring or for some other reason, or looseness at the connecting

parts at the time of its inspection or service. If there is some defective point, repair the insulation or replace the wiring

harness. (The band becomes breakable when becoming old. Be sure to substitute in such a case.)

(3) After completion of service for the tractor, etc., protect wiring at the plugging parts with vinyl tube, use clamping

fixtures with vinyl cover, and check that the figures are not in direct contact with wiring. (Replace uncovered

fixtures.) Especially check carefully where wiring may be caught between something.

(4) Check very carefully where positive current flows constantly and confirm sheathing is free form troubles.

1) Starting motor

2) Alternator

3) Key switch

(5) After check, protect the wiring with corrugated tube or the like.

Loading...

Loading...