76

Part Inspection Items

Standard

Dimension

Standard

Assembling

Va l ue

Repair

Va lu e

Service

Limit

Remarks

Connecting rod

Torsion of large end and small end holes

(per 100 mm)

Less than

0.08

More than

0.2

Parallelism of large end and small end holes

(per 100 mm)

Less than

0.05

More than

0.15

Longitudinal play of connecting rod and crank pin 0.1

0.3 0.7

Clearance between connecting rod bearing and crank

pin

0.035 –

0.083

0.2

Oil

clearance

Connecting rod bearing (bore x width)

φ44×19.8

Connecting rod tightening torque N⋅m {kgf

m}

49.0 – 53.9

{5.0–5.5}

Weight variation of piston after assembly (g) Less than 10

Crank shaft

Journal dia.

φ58

φ57.957 –

57.97

φ57.90

Crank pin dia.

φ44

φ43.964 –

43.975

φ43.90

Journal and pin finishing accuracy 1.6Z

Run-out of crankshaft

Less than

0.03

0.06

Axial play of crankshaft 0.1

0.4 0.5

Thrust washer thickness 3 2.95 – 3.00 2.8

Bush (journal metal) bore × outside dia.

φ58×φ62

Clearance between crank journal and bush (journal

metal)

0.044 –

0.116

0.2

Oil

clearance

Center bearing (bore × outside dia.)

φ58×φ62

Clearance between crank journal and center bearing

0.044 –

0.116

0.2

Oil

clearance

Bearing holder (upper and lower) tightening torque

N⋅m {kgf⋅m}

49 – 53.9

{5.0 – 5.5}

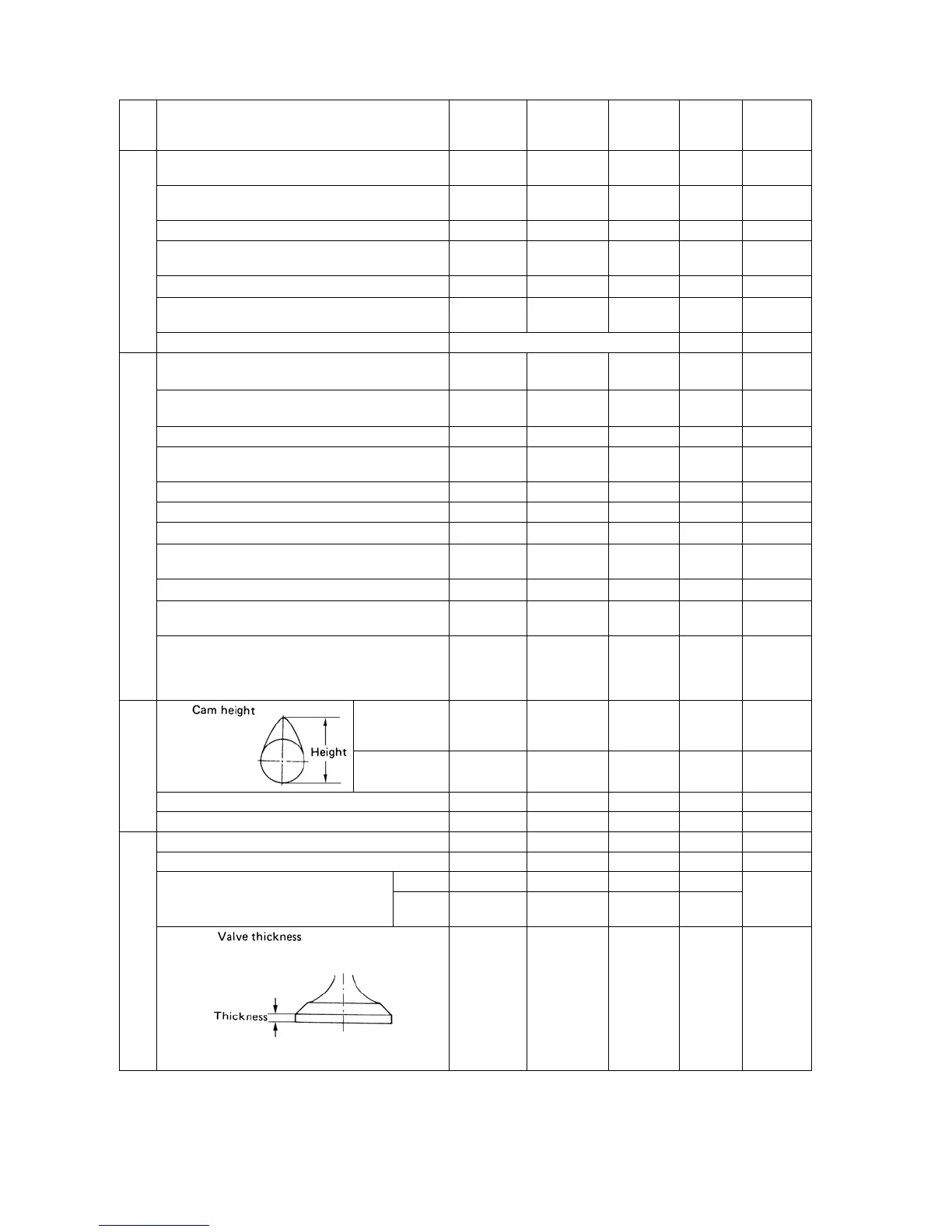

Camshaft

138X

For intake and

exhaust valves

34.441 –

34.5076

34.1

For injection

pump

42.99 –

43.01

42.8

Cam shaft runt 0.03 0.1

Cam gear backlash 0.08 0.25

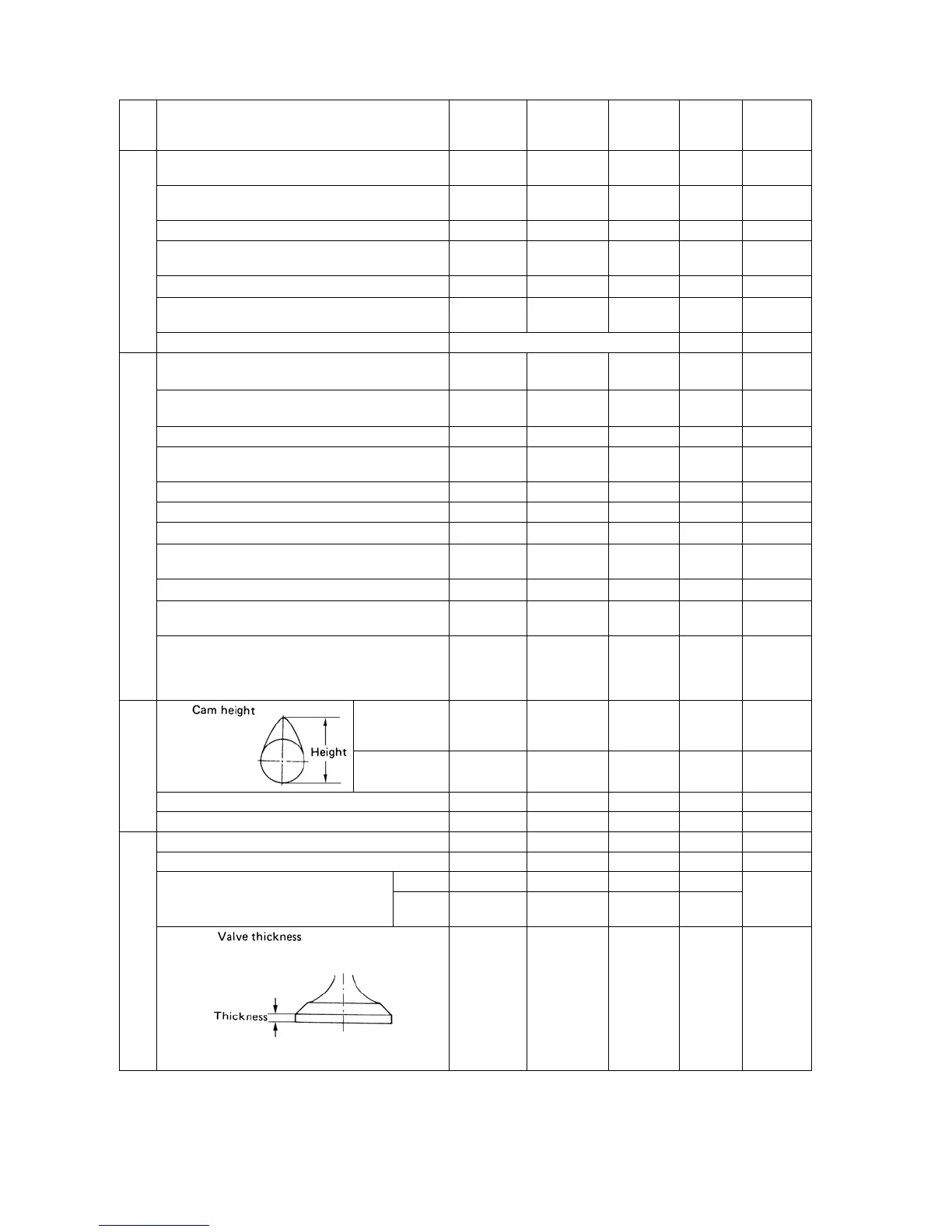

Valve

Intake valve stem 6.97 6.955 – 6.97 6.89

Exhaust valve stem 6.95 6.94 – 6.95 6.84

Clearance between valve stem and valve

guide

Intake 0.03 – 0.06 0.2

at cold

Exhaust

0.045 –

0.075

0.25

139X

1.0

0.775 –

1.075

0.5

Loading...

Loading...