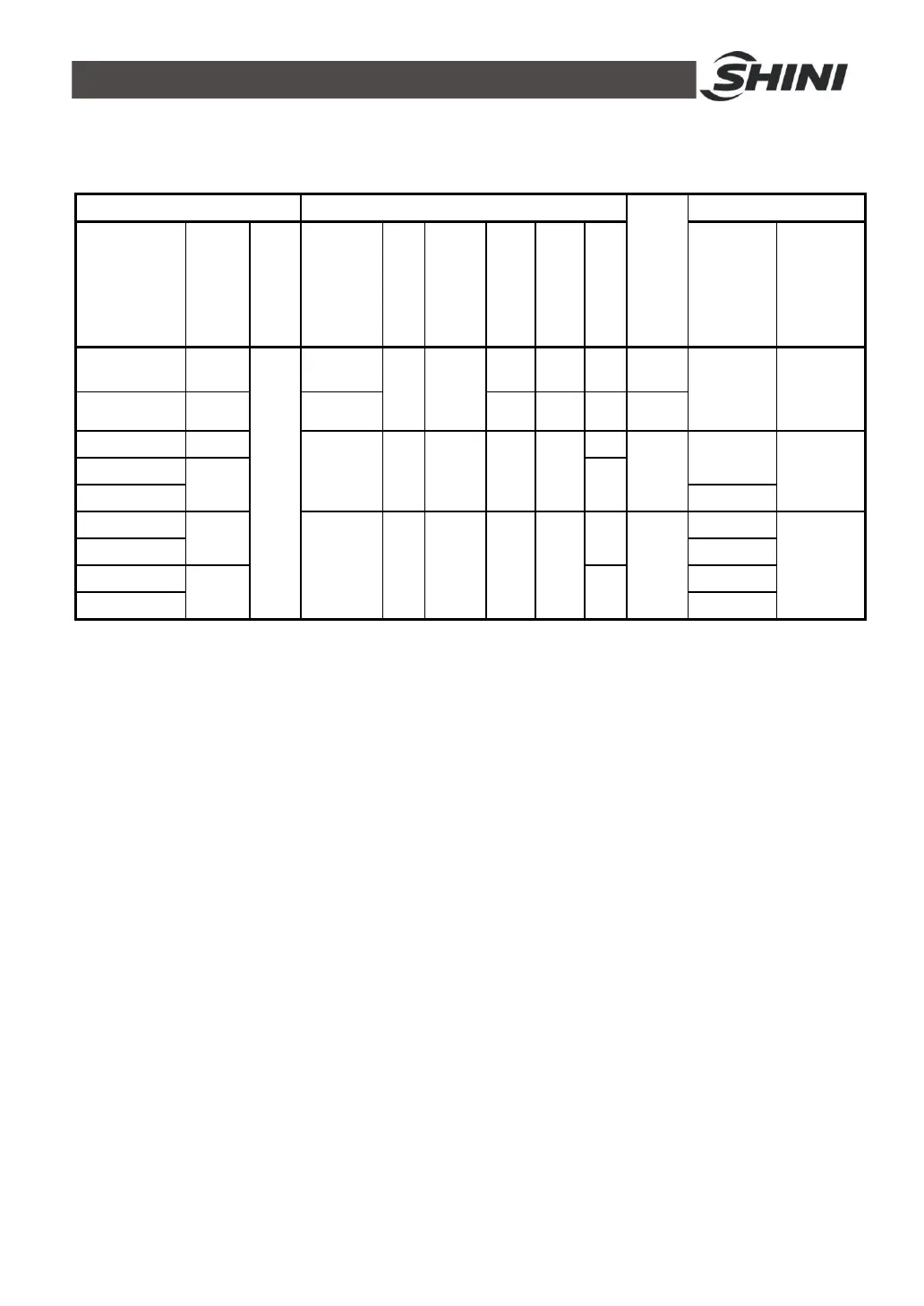

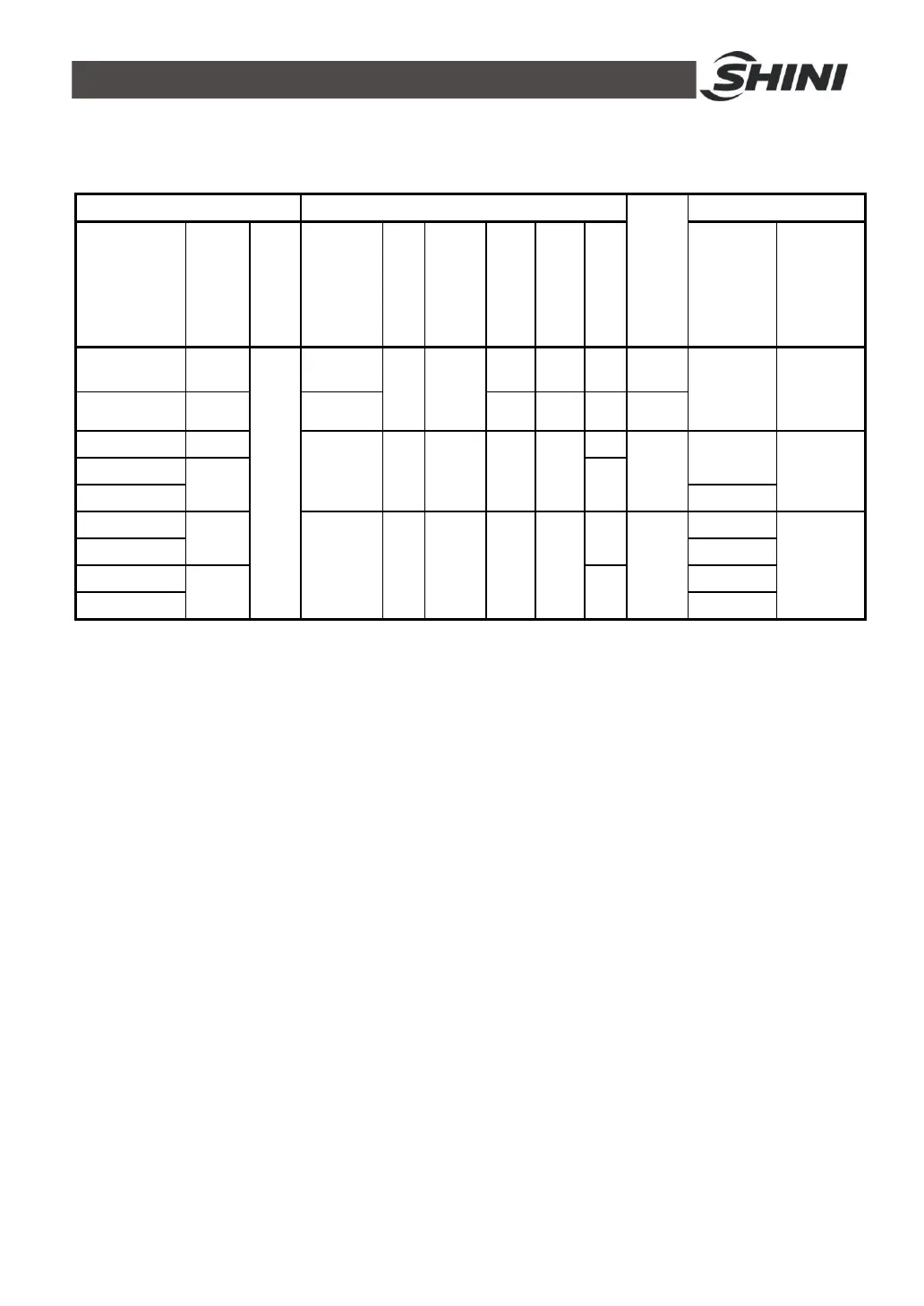

13(61)

For Conveying Raw Material Contains 100% Powder (PLATE FILTERS are fitted

to the powder receiver)

Main Unit Powder Receiver Dimensions (mm)

Model

Motor

Power

(kW)

(50/60Hz)

Specifi-

cation

Applied to Model

Motor

Power

(kW)

(50/60Hz)

Specifi-

cation

Applied

to

Model

Filter

Cloth

Quantity

Motor

Power

(kW)

(50/60Hz)

Specifi-cation

Applied to

SAL-1HP-UGP

0.75 /

0.85

SHR-P-30U-1

12L Φ270

300

1

SAL-2HP-UGP 1.5 / 1.8

SHR-P-30U-2

1.5”

1.5”

30L Φ380

400

2

1000×400×500

1325×730×470

SAL-3.5HP-UGP 2.4 / 2.6

800

SAL-5HP-UGP

1380×490×570

SAL-5HP-UGP-D

3.7 / 4.2

SHR-P-60U-3

2” 2” 60L Φ440

1200

3

1380×690×570

1500×780×500

SAL-7.5HP-UGP 1830×585×675

SAL-7.5HP-UGP-D

5.5 / 6.3

1500

1830×740×675

SAL-10HP-UGP 1830×585×675

SAL-10HP-UGP-D

7.5 / 8.6

3Φ

SHR-P-90U-5

2.5”

2.5” 90L Φ550

2000

5

1830×740×675

1640×890×635

Note: 1) "P" stands for powder loader, "D" stands for double stage blower. We reserve the right to change

2) All SAL-UGP series has vacuum breaking valve to protect the blower. specifications without prior notice.

3) PU heat-resistant material pipe is optionally available.

4) Test condition of conveying capacity: Use dried powder plastic material without any viscosity and its bulk density is 0.6kg/L,

vertical conveying height: 4m, horizontal conveying distance: 5m.

5) Collective hopper can be optionally selected if needed.

6) Power supply: 3Ф, 230/400/460/575V, 50/60Hz.

Loading...

Loading...