16(61)

2. Structure characteristics and working principle

2.1 Main Functions

SAL-UGP "Euro" separate-vacuum hopper loader are applicable to convey the

mixture of plastic granule and powder or all powders. It makes good use of

motor generated vacuum to form a pressure gap within hopper, by which

means to convey.

2.1.1 SAL-UGP Working Principle

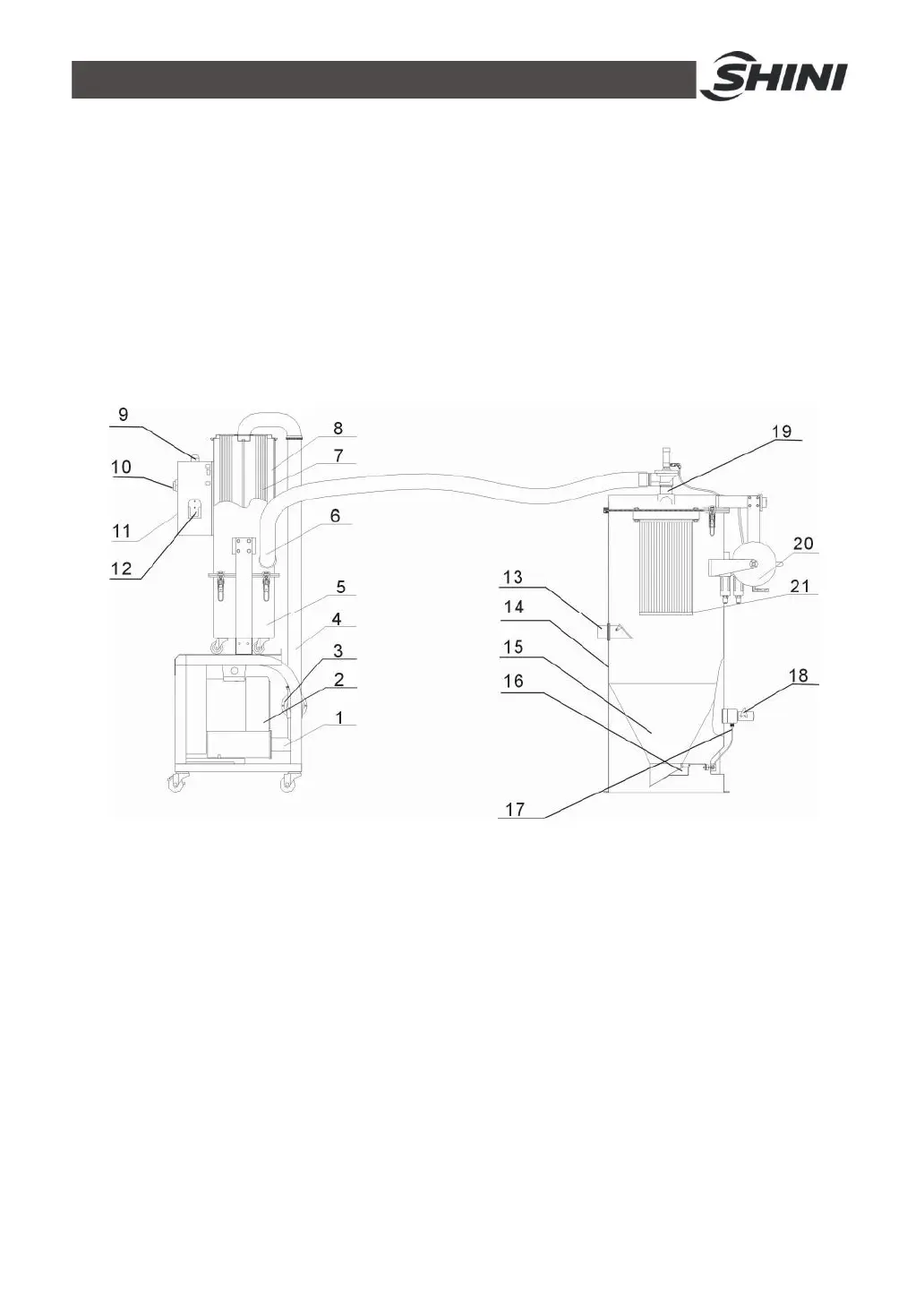

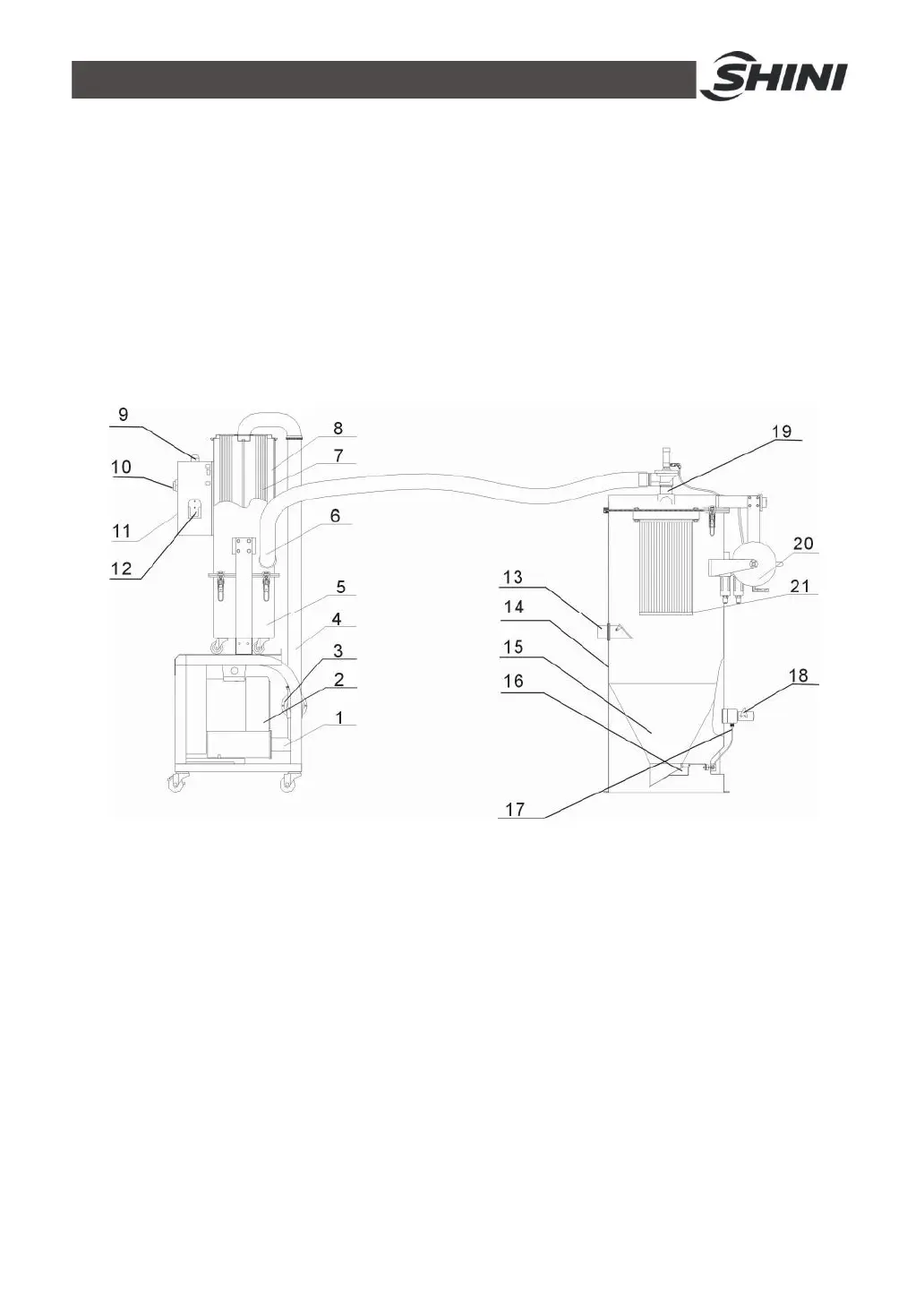

Names of Parts:

1. Air suction pipe (blower use) 2. Blower 3. Vacuum breaking diaphragm valve

4. Steel wired plastic pipe 5. Dust collective barrel

6. Air suction pipe (hopper use) 7. Filter 1 8. Filtering barrel

9. Red alarm light 10. Main power switch 11. Electrical control box

12. Manual controller 13. Material inlet pipe 14. Hopper

15. Crew material 16. Non-return flap 17. Magnetic proximity switch

18. Wiring box 19. Diaphragm valve 20. Storage tank

21. Filter 2

Picture 2-1:SAL-UGP Working Principle

After starting the machine, blower (2) begins to work to produce high-pressure

vacuum inside of material hopper (15), meanwhile close the reverse stopping

flap (17). Materials will be drawn into material hopper by pressure difference

through material inlet (13). When material suction is completed, motor stops

Loading...

Loading...