Product description

26 © SICK AG · Germany · All rights reserved · Subject to change without notice 8013796/ZM63/2017-05-09

Operating Instructions

LMS5xx Laser Measurement Sensors

Chapter 3

Influences of object surfaces on the measurement

The signal received from a perfectly diffuse reflecting white surface corresponds to the

definition of a remission of 100%. As a result of this definition, the remissions for surfaces

that reflect the light bundled (mirrored surfaces, reflectors), are more than 100%.

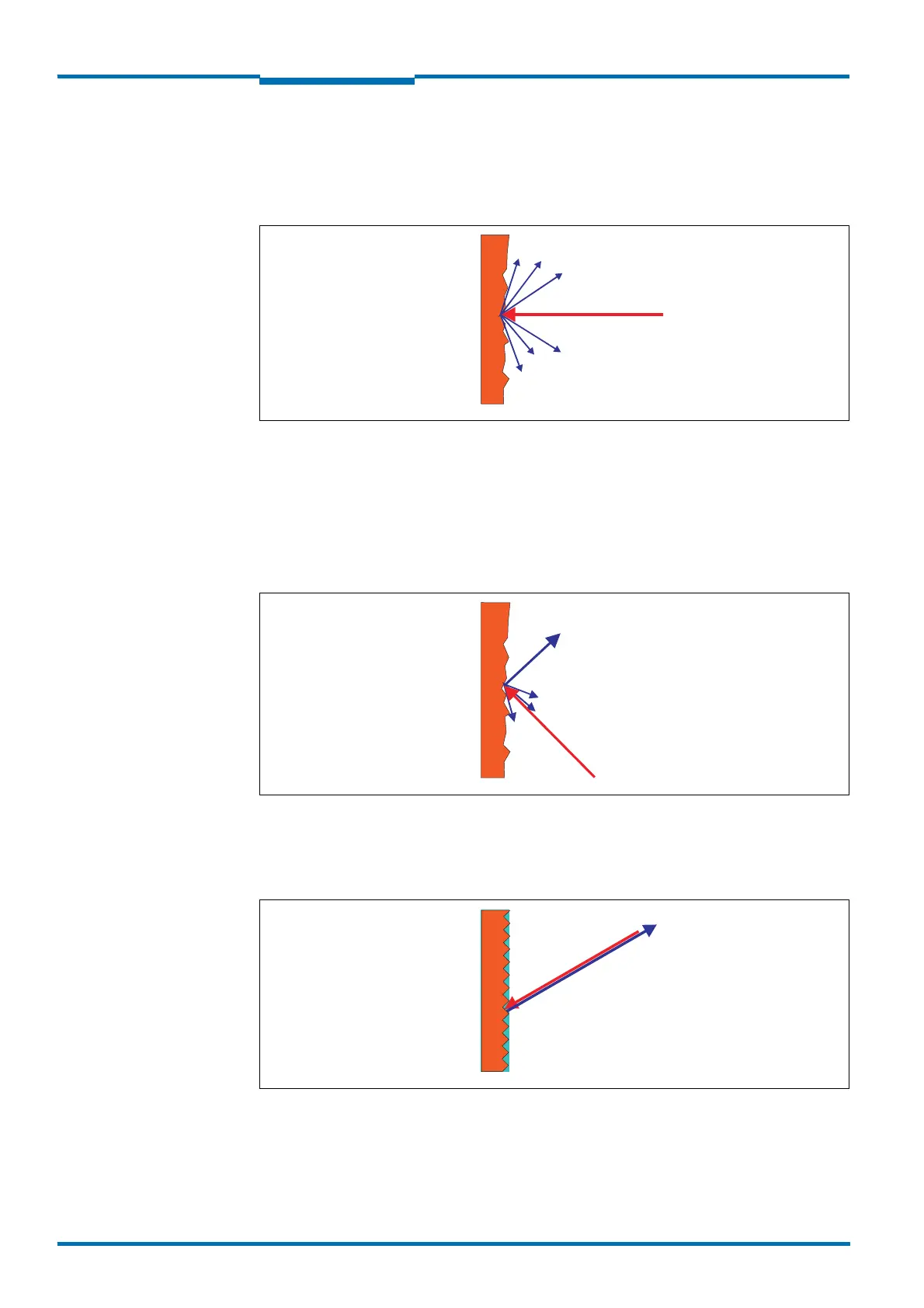

Fig. 7: Reflection of the laser beam at the surface of an object

The majority of surfaces reflect the laser beam diffusely in all directions (Fig. 7).

The reflection of the laser beam will vary as a function of the surface‘s structure and colour.

Light surfaces reflect the laser beam better than dark surfaces and can be detected by the

LMS5xx over larger distances. Bright white plaster reflects approx. 100% of the incident

light, black foam rubber approx. 2.4 %. On very rough surfaces, part of the energy is lost due

to shading. The scanning range of the LMS5xx will be reduced as a result.

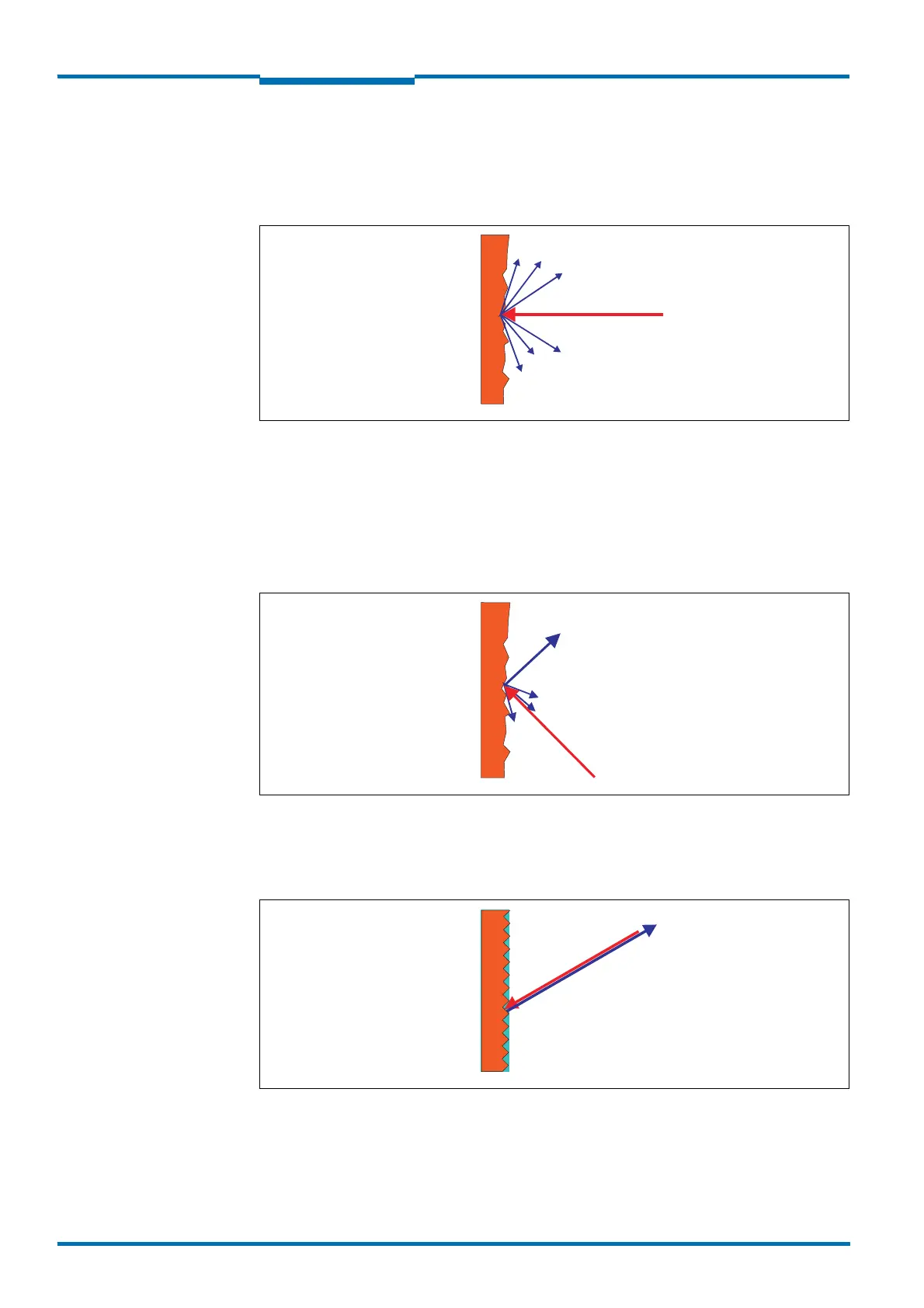

Fig. 8: Reflection angle

The reflection angle is the same as the angle of incidence. If the laser beam is incident

perpendicularly on a surface, the energy is optimally reflected (Fig. 9). If the beam is

incident at an angle, a corresponding energy and scanning range loss occurs (Fig. 8).

Fig. 9: Degree of reflection

Loading...

Loading...