Product description

50 © SICK AG · Germany · All rights reserved · Subject to change without notice 8013796/ZM63/2017-05-09

Operating Instructions

LMS5xx Laser Measurement Sensors

Chapter 3

3.14.3 Distance between LMS5xx and the object/surface to be monitored

The laser beam diverges with increasing distance from the LMS5xx. In the scan area the

floor or a wall may then be continuously detected, as the laser beam is incident on it.

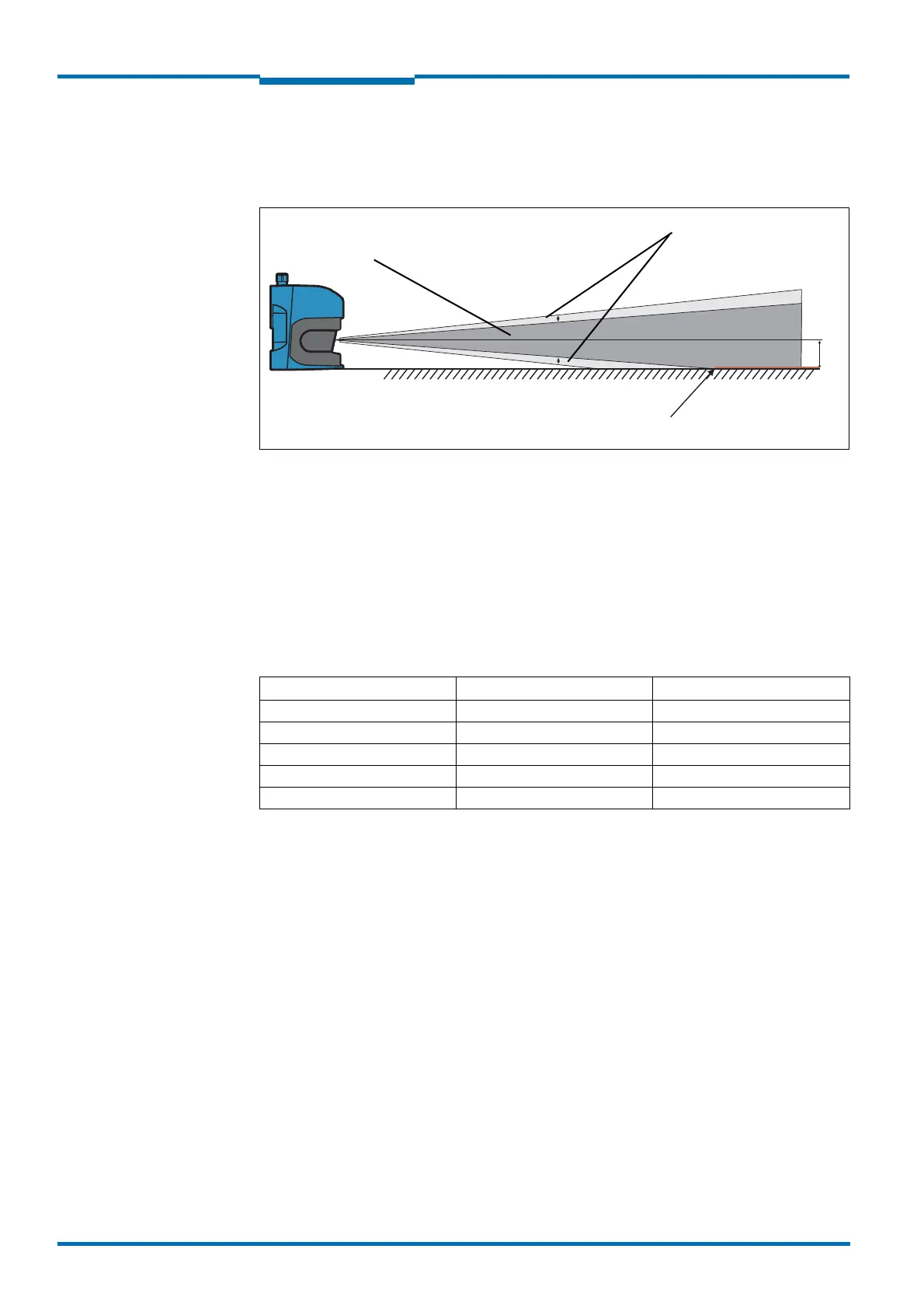

Fig. 26: Increase in the size of the beam and safety supplement

The optical axis is used as the reference plane for the distance to be maintained from the

floor or the wall; on a vertically mounted LMS5xx this axis is approx. 116 mm (4.57 in) above

the bottom edge of the housing.

The distance-dependent increase in the size of the beam can be calculated using the

formula:

Beam diameter = distance (mm) × divergence + spot size on front screen

For the values please see Tab. 43: “Data sheet LMS5xx” on page 101.

The following table shows some example values:

For the assessment of whether the laser beam can be incident on an object or the wall, the

distance of half the beam diameter from the optical axis is used.

Recommendation Take into account a safety supplement of approx. 5 mm per meter (0.06 in/ft).

Distance LMS5xx (HR) LMS5xx (SR)

5 m 37 mm 73 mm

10 m 61 mm 133 mm

15 m 85 mm 192 mm

20 m 108 mm 252 mm

50 m 250 mm 609 mm

Tab. 20: Beam diameter on target (diagonal) at different distances from the LMS5xx

Safety supplement

5 mm/m (0.06 in/ft)

From 15 m (49.21 ft) continuous detection

Optical axis

Expanding laser beam

Loading...

Loading...