233/248

Building Technologies Division Basic documentation LMV36... CC1P7544en

Infrastructure & Citiies Sector 30 Error code list 25.09.2013

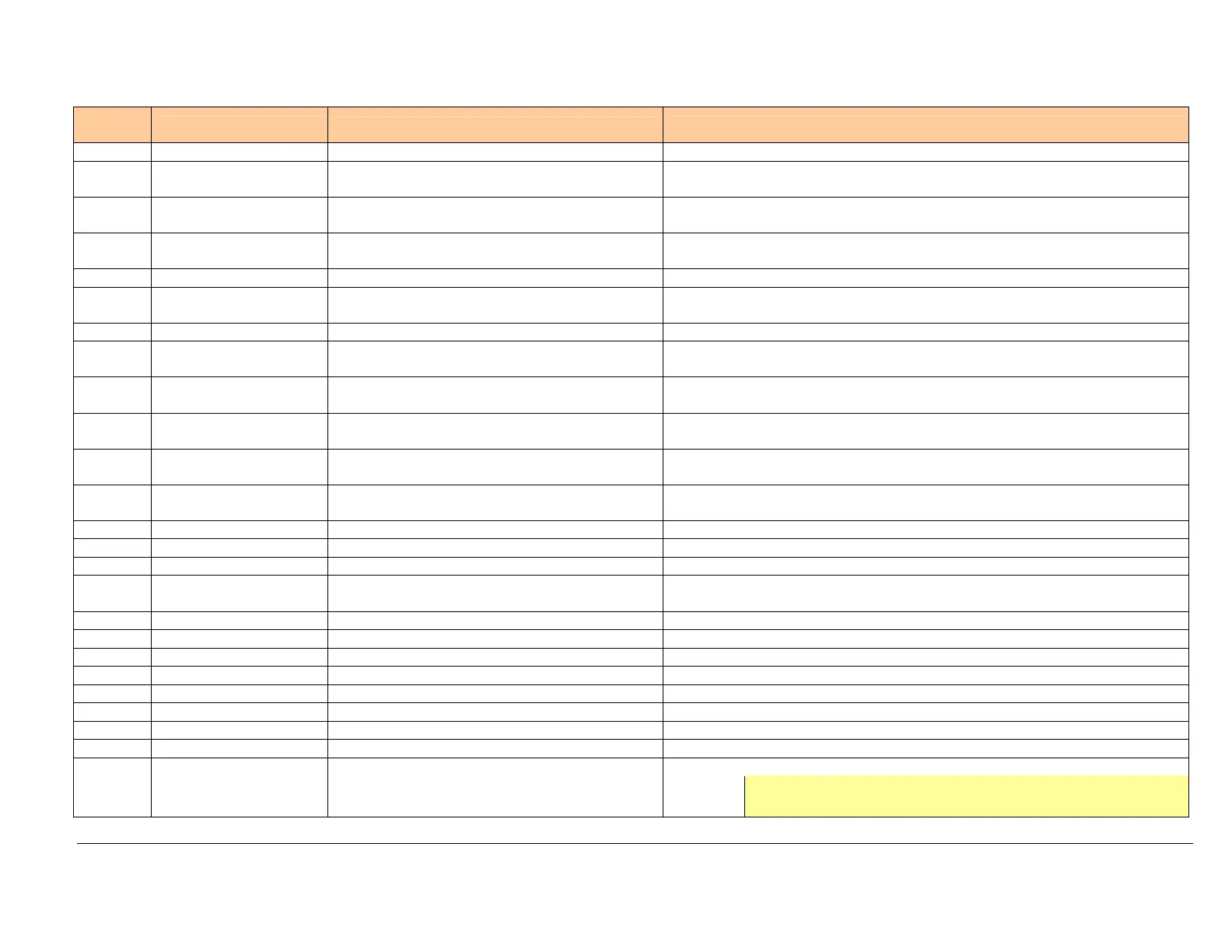

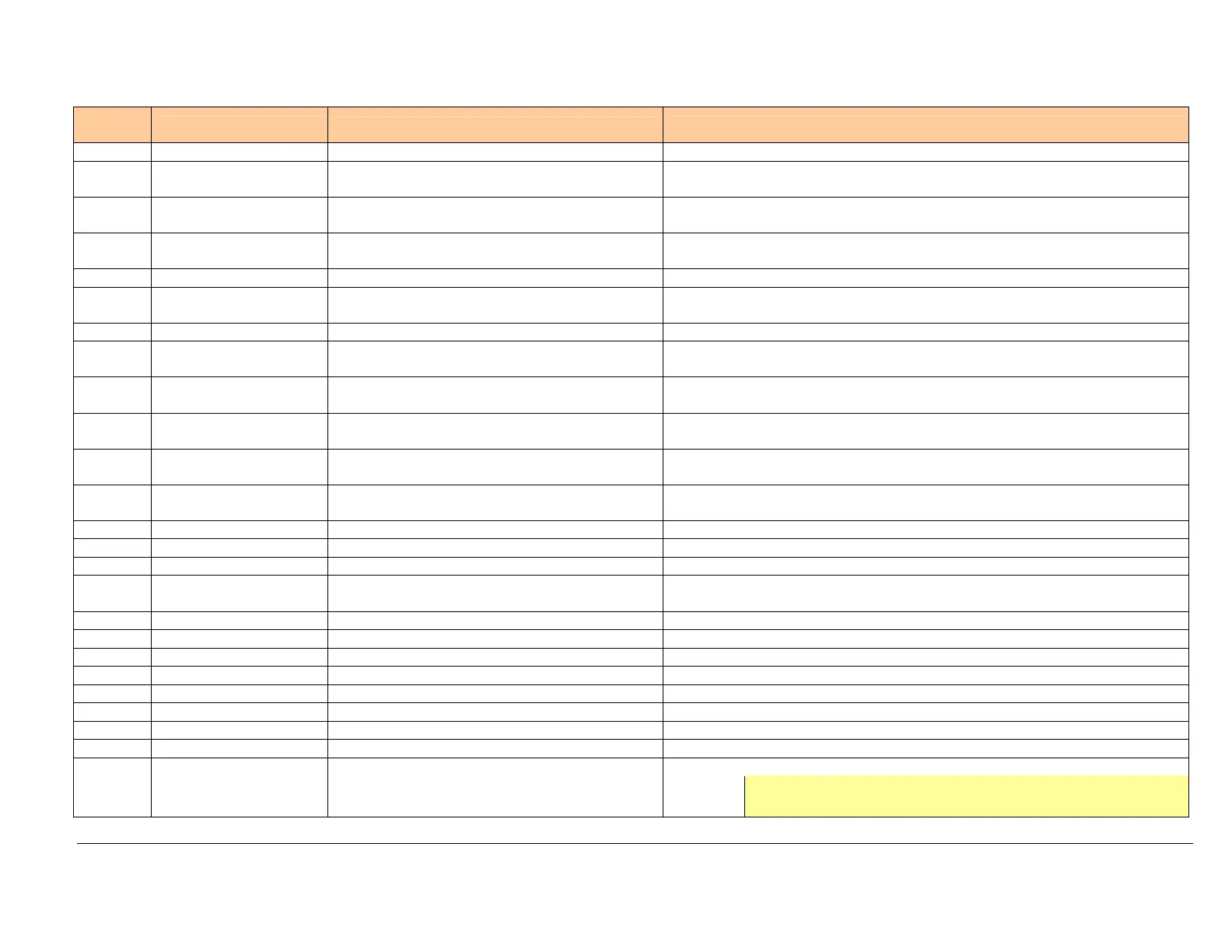

Error

code

Diagnostic code Meaning for the LMV36... system Remedy

prevention

19

Safety loop/burner flange, extraneous light, combustion

pressure – start prevention

21

Safety loop/burner flange, air pressure, combustion pressure –

start prevention

23

Safety loop/burner flange, extraneous light, air pressure,

combustion pressure – start prevention

65 Safety loop/burner flange, POC – start prevention

67

Safety loop/burner flange, extraneous light, POC – start

prevention

69 Safety loop/burner flange, air pressure, POC – start prevention

71

Safety loop/burner flange, extraneous light, air pressure, POC

– start prevention

81

Safety loop/burner flange, combustion pressure, POC – start

prevention

83

Safety loop/burner flange, extraneous light, combustion

pressure, POC – start prevention

85

Safety loop/burner flange, air pressure, combustion pressure,

POC – start prevention

87

Safety loop/burner flange, extraneous light, air pressure,

combustion pressure, POC – start prevention

23 # Gas pressure switch-min (Pmin) / heavy oil direct start

0 No minimum gas pressure Check wiring to see if there is an open-circuit (X5-01)

1 Gas shortage – start prevention Check wiring to see if there is an open-circuit (X5-01)

2 Heavy oil direct start

Check wiring to see if there is an open-circuit (X9-04)

Check that the oil is preheated correctly

50 # Internal error

Make a reset; if error occurs repeatedly, replace the unit

51 # Internal error

Make a reset; if error occurs repeatedly, replace the unit

55 # Internal error

Make a reset; if error occurs repeatedly, replace the unit

56 # Internal error

Make a reset; if error occurs repeatedly, replace the unit

57 # Internal error

Make a reset; if error occurs repeatedly, replace the unit

58 # Internal error

Make a reset; if error occurs repeatedly, replace the unit

60 # Internal error: No valid heat source

1 Analog output preset valid – prevention of startup Check wiring of analog predefined output to see if there is an open-circuit / loose contact

2 Analog output preset valid – default output low-fire

Check wiring of analog predefined output to see if there is an open-circuit / loose contact

Note:

This information is provided in connection with the thermal shock protection

Loading...

Loading...