5

ShopTurn Functions 08/2005

5.5 Millin

5

♥ Siemens AG, 2005. All rights reserved

5-244 SINUMERIK 840D sl Operation/Programming ShopTurn (BAT) – 08/2005 Edition

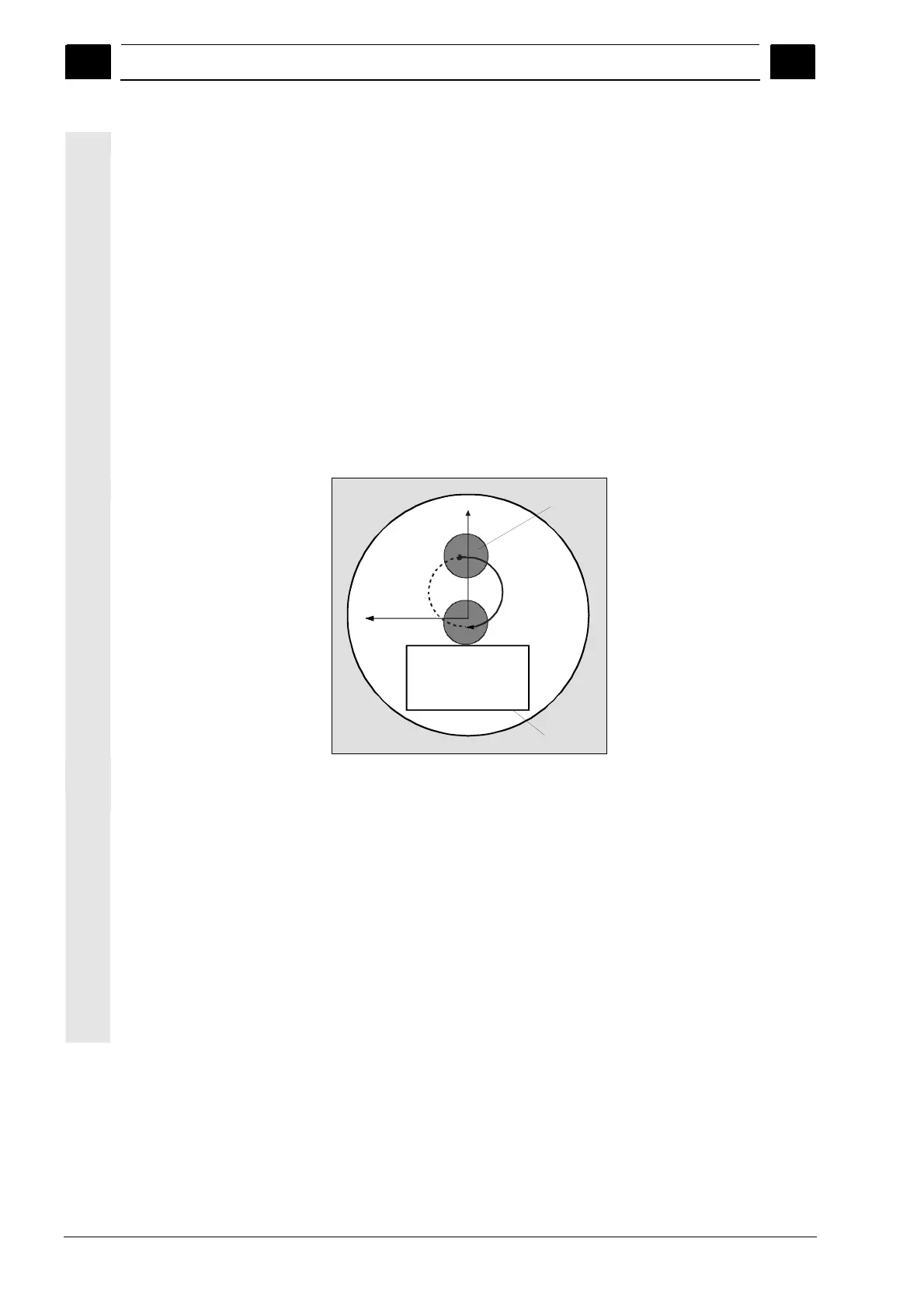

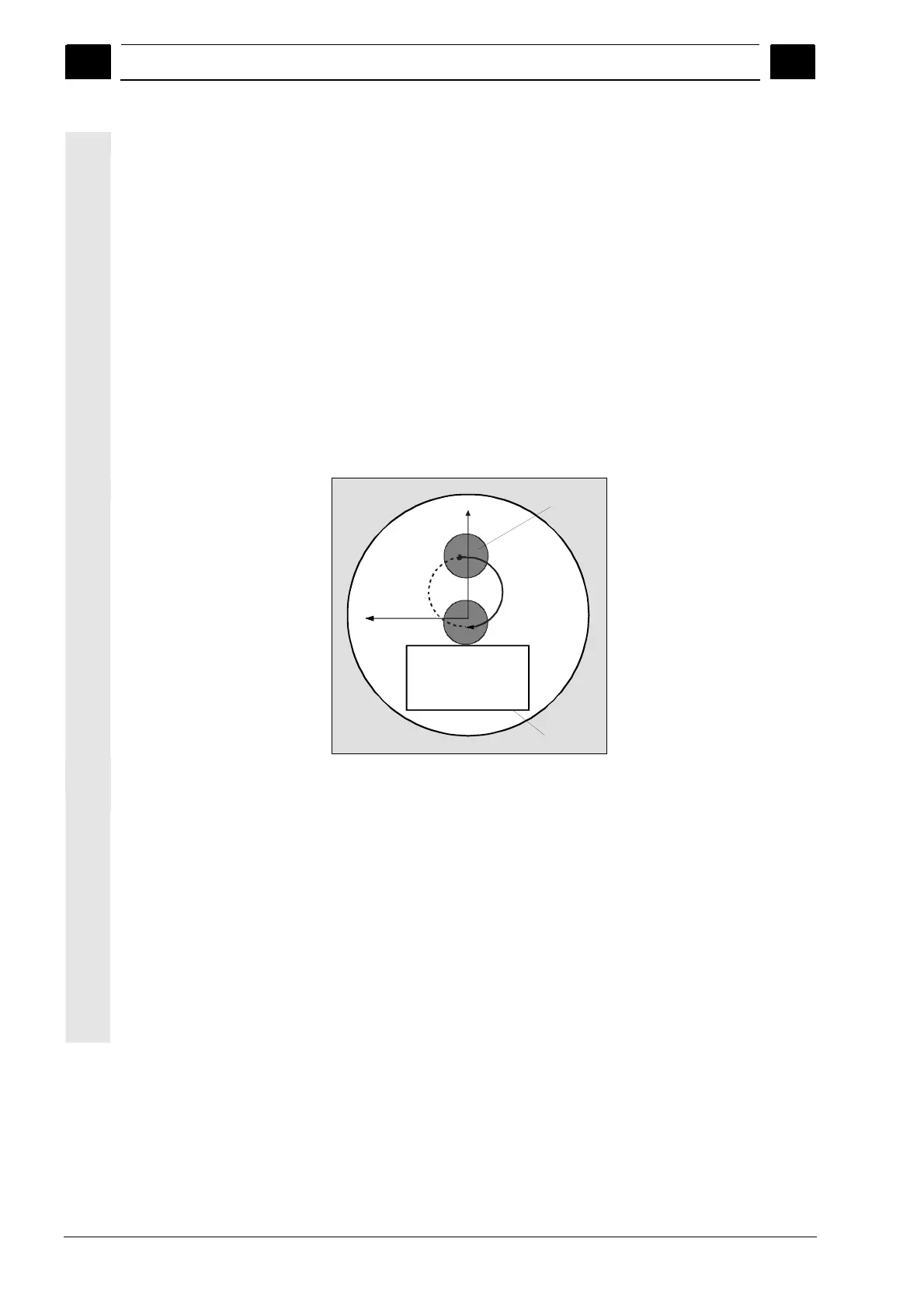

Approach/retraction

1. The tool approaches the starting point at rapid traverse at the

height of the retraction plane and adjusts to the safety clearance.

The starting point is on the positive X axis rotated through α0.

2. The tool traverses the spigot contour sideways in a semicircle at

machining feed. The tool first executes infeed at machining depth

and then moves in the plane. The spigot is machined as a function

of the programmed machining direction (climb/conventional) in a

clockwise or counterclockwise direction.

3. When the spigot has been circumnavigated once, the tool retracts

from the contour in the plane in a semicircle and then infeeds to

the next machining depth.

4. The spigot is approached again in a semicircle and

circumnavigated once. The process is repeated until the

programmed spigot depth has been reached.

5. The tool moves back to the safety clearance at rapid traverse.

X

Y

Retracting

contour

Approaching

contour

Tool

Rectangular

spigot

Approaching and retracting from the rectangular spigot in a semicircle

Machining type

You can select the machining mode for milling the rectangular spigot

as follows:

Roughing

Roughing involves moving round the spigot until the programmed

finishing allowance has been reached.

Finishing

If you have programmed a finishing allowance, the spigot is moved

round until depth Z1 is reached.

Chamfer

Chamfering involves edge breaking at the upper edge of the

rectangular spigot.

Loading...

Loading...