Service Manual SC 7000 and SC 9000XL Patient Monitors

86 Siemens Medical Systems, EM-PCS, Danvers ASK-T898-03-7600

NOT A CONTROLLED DOCUMENT

7k9kXLSM.c5.CD_ROM.fm/04-99/kaupp

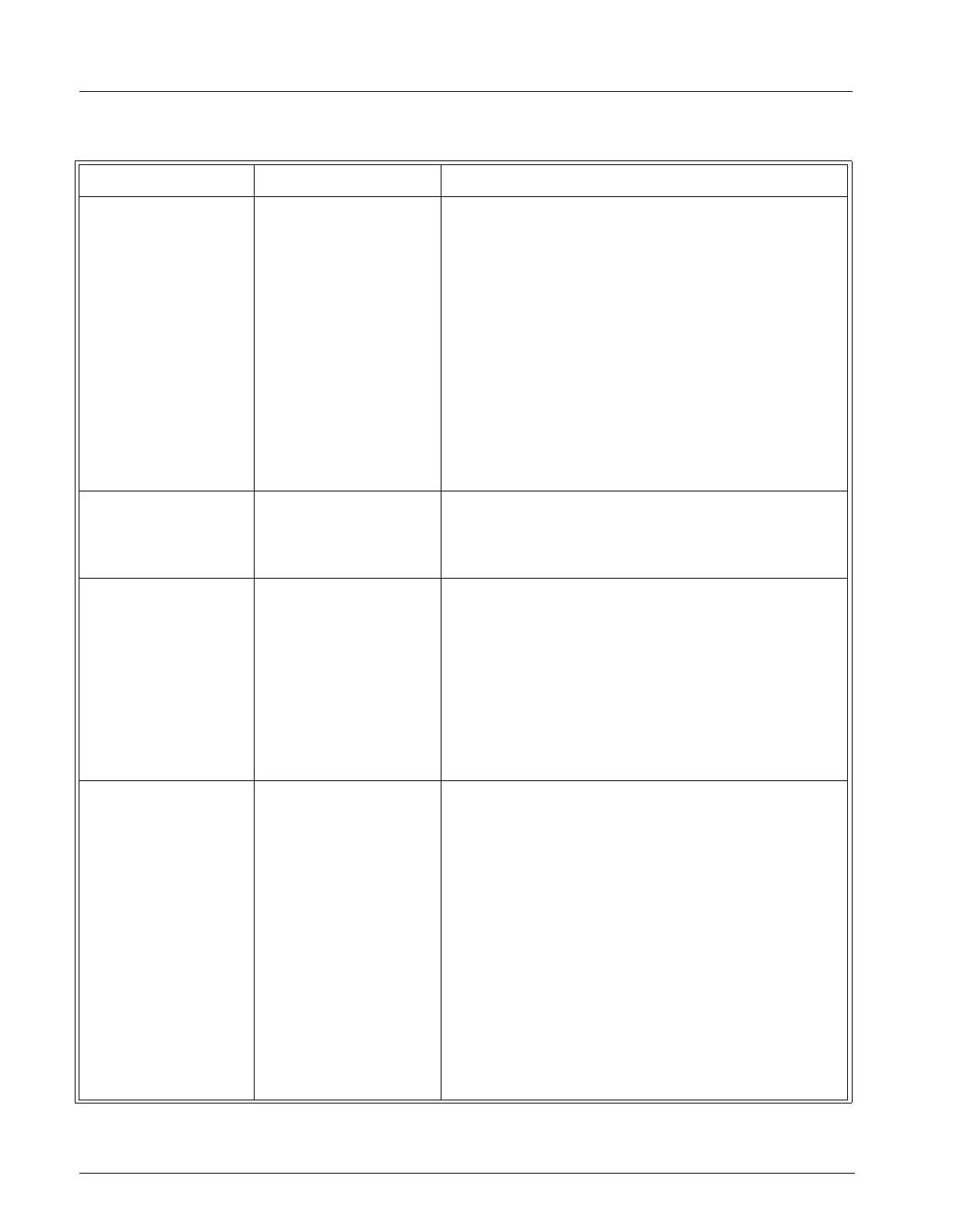

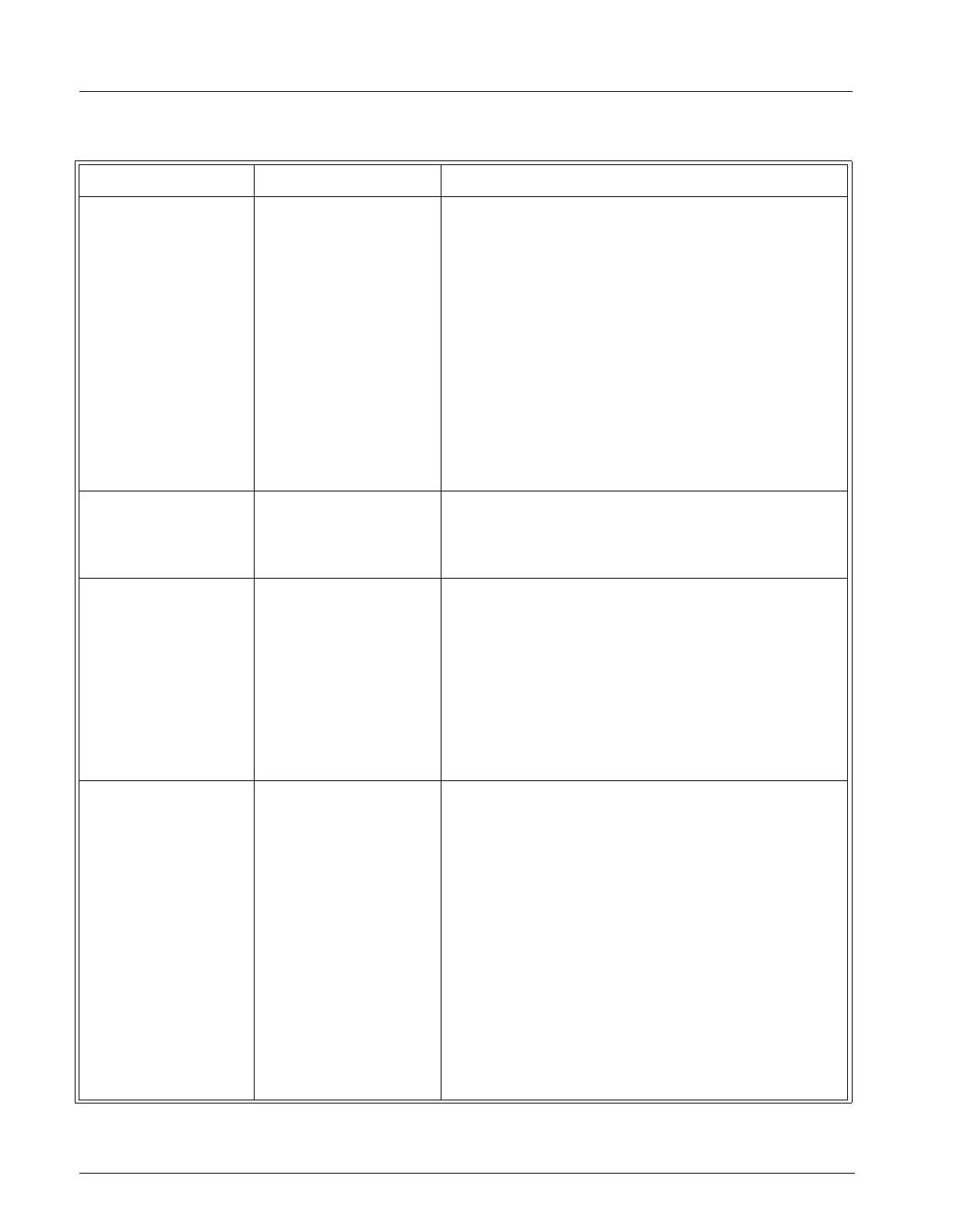

NBP pump starts, but

cuff fails to inflate/

deflate properly

Cuff assembly

malfunction

NBP pneumatic system

malfunction

1. Recheck cuff assembly and installation, and replace

cuff assembly if defective.

2. If problem persists, remove rear cover and check

hose routing to cuff connector in NBP compartment

in rear housing.

3. If problem persists, open monitor and check that

pneumatic tubing to NBP transducer properly routed

and not obstructed.

4. Close monitor and perform characterization

procedure if tubing rerouted or obstruction removed

(see Section 4.7.4 on page 44 in Chapter 3).

5. If problem persists, replace NBP Subassembly.

6. If problem persists, contact TSS in Solna or Danvers.

NBP fails Interval

Mode or Safety Timer

Check

Main Processor PCB

Subassembly

malfunction

Software problem

1. Replace Main Processor PCB Subassembly.

2. If problem persists, contact TSS in Solna or Danvers

NBP fails hardware

overpressure check

Blockage between

pump manifold and cuff

connector

Main Processor PCB

malfunction

1. Power-cycle monitor to ensure that measurement

timout did not trigger premature pressure release,

and recheck.

2. If problem persists, remove rear cover and assure no

blockage in tubing between pump manifold and cuff

connector.

3. If problem persists, replace Main Processor PCB

Subassembly.

4. If problem persists, contact TSS in Solna or Danvers.

NBP parameter box

fails to appear when

cuff hose plugged into

NBP module

MAIN screen display

mode set for Manual

Cuff sensor defective or

not plugged into

Connector I/O PC

Board.

Main Processor PCB

malfunction

1. Assure

MAIN

screen display mode set to automatic.

2. If parameter box fails to appear, remove rear cover

and check that cuff sensor cable is plugged into X8

on Connector I/O PC Board.

3. • If sensor unplugged, plug sensor into X8 on

Connector I/O PC Board, and retest. If OK, return

monitor to clinical service.

• If sensor plugged in, unplug sensor and check for

continuity across pins of sensor cable connector.

— If continuity OK, (≈1.5Ω) replace Main

Processor PCB Subassembly.

— If continuity not OK, replace Rear Housing

Subassembly.

4. If problem persists, contact TSS in Solna or Danvers.

Table 5-9 NBP Malfunctions (Continued)

Symptom(s) Possible Cause(s) Troubleshooting and Remedial Action

Loading...

Loading...