8.9.2 Faults in operation

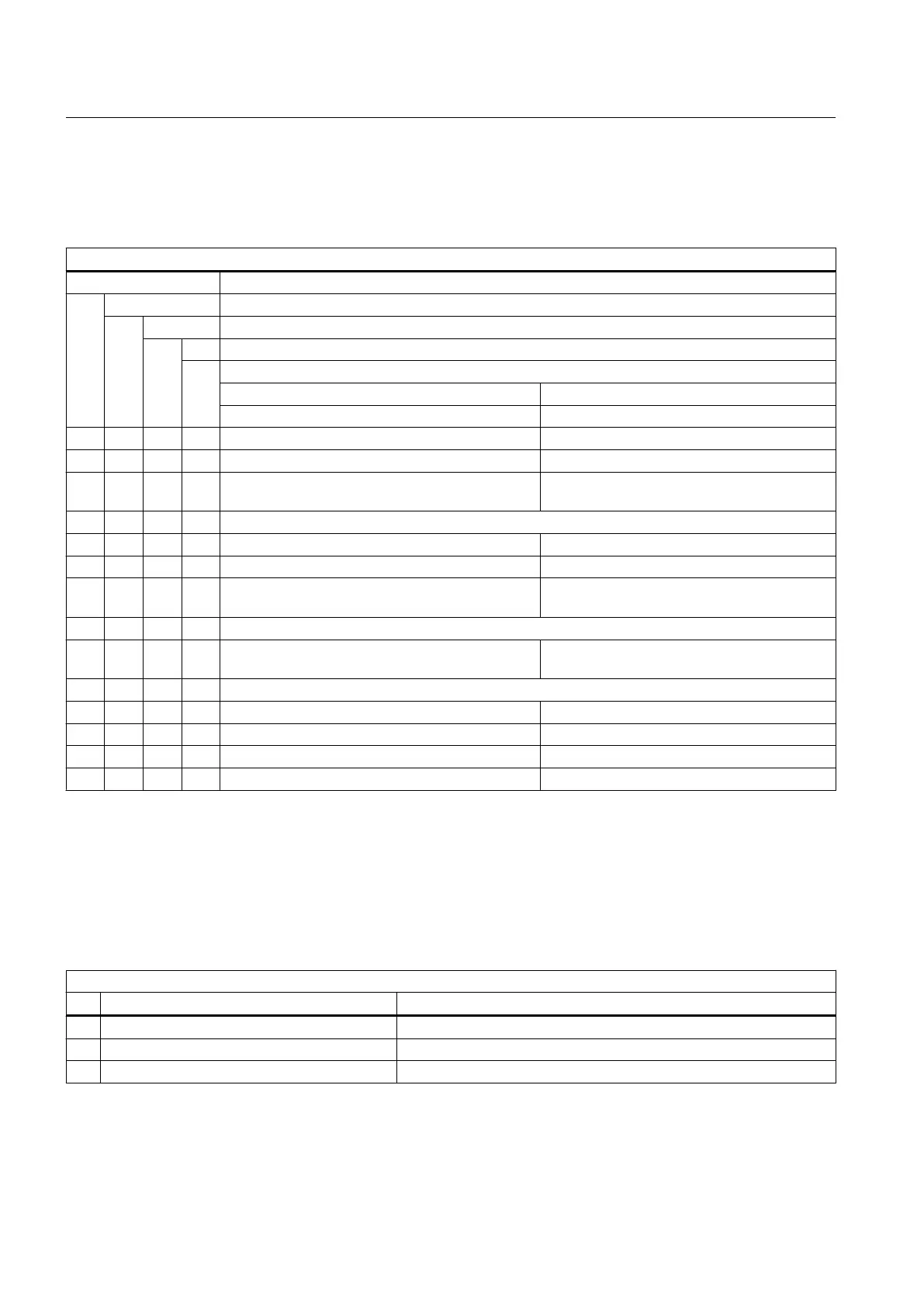

Table 8-2 Faults in operation

Symptoms of fault

↓ General uneven running of machine

↓ Vibrating brushes

↓ High temperature rise (general)

↓ Severe brush sparking

Possible causes of faults Remedial measures

Plant fault

X Coupled motor out of balance Check coupling, rebalance system

X X Poor alignment Align motor set

X X X Resonance in system Improve installation conditions or reduce exci‐

tation of vibration

Operating mode or operating error

X Continuous light-load duty (partial load) Change number of brushes and/or material

X Temporary overload Correct current limit on converter

X Continuous overload Correct current limit on converter/reduce down

periods of rest

Cooling fault

X Cooling air-flow rate too low (commutator temper‐

ature too high)

Improve ventilation circuit

Component defect

X Interturn fault Repair winding

X X Out-of-round commutator Rework commutator

X Rotor imbalance Balance rotor

X Bearing damage Repair or replace bearing

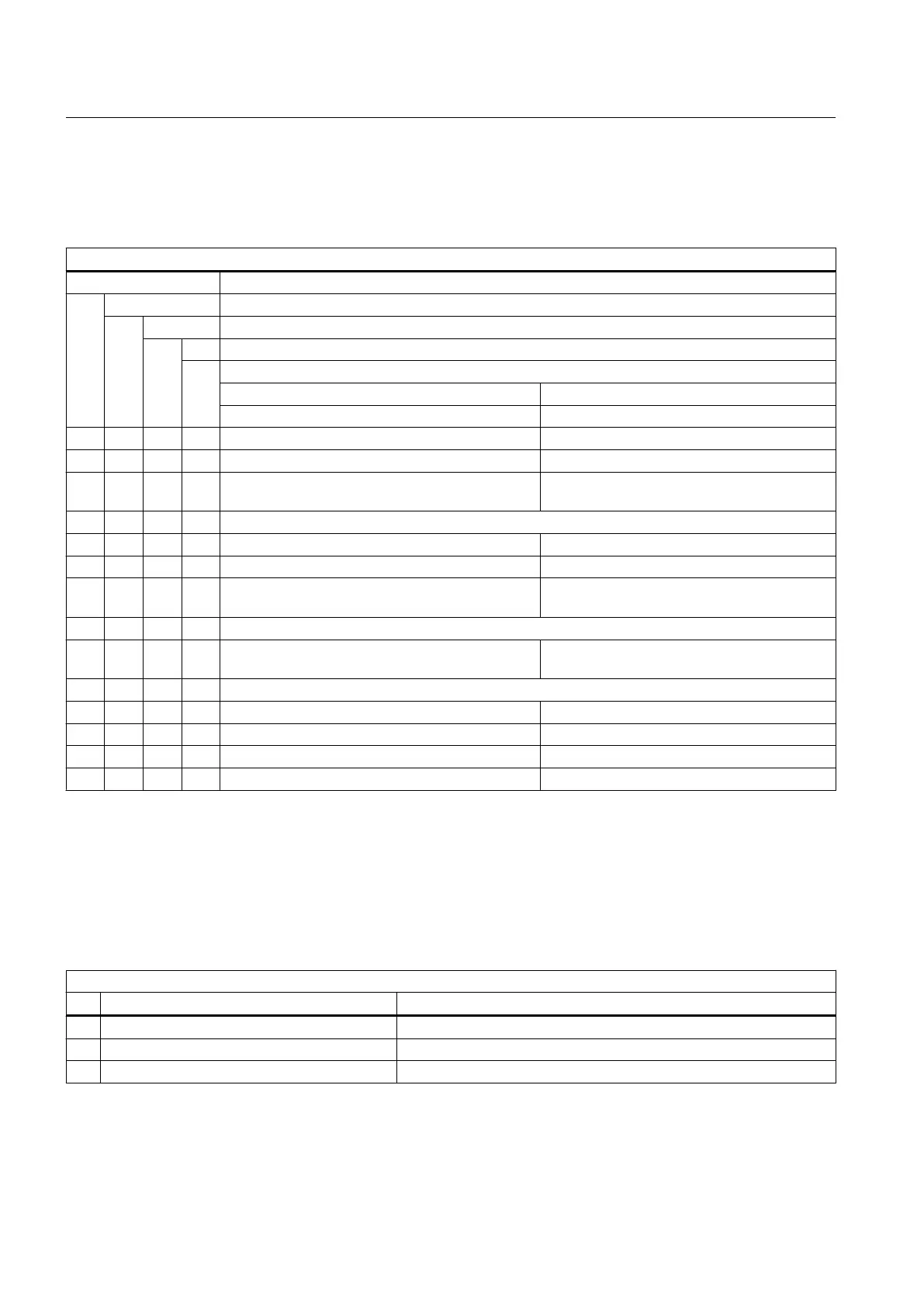

8.9.3 Faults at the external fan

The following table shows the possible causes of and remedial measures for faults on forced-

ventilated machines.

Table 8-3 Cooling system faults

↓ High temperature rise with load

Possible causes of faults Remedial measures

X Wrong direction of rotation of the external fan Check the electrical connections to the external fan.

X External fan is not running Check the external fan and its connections.

X Reduced air flow Check the air ducts; clean the machine.

Operation

8.9 Faults

SIMOTICS DC 1GG5

76 Operating Instructions 02/2016

Loading...

Loading...