8.9.4 Roller bearing faults

Note

Damage to roller bearings can be difficult to detect in some cases. If in doubt, replace the

bearing. Use other bearing designs only after consulting the manufacturer.

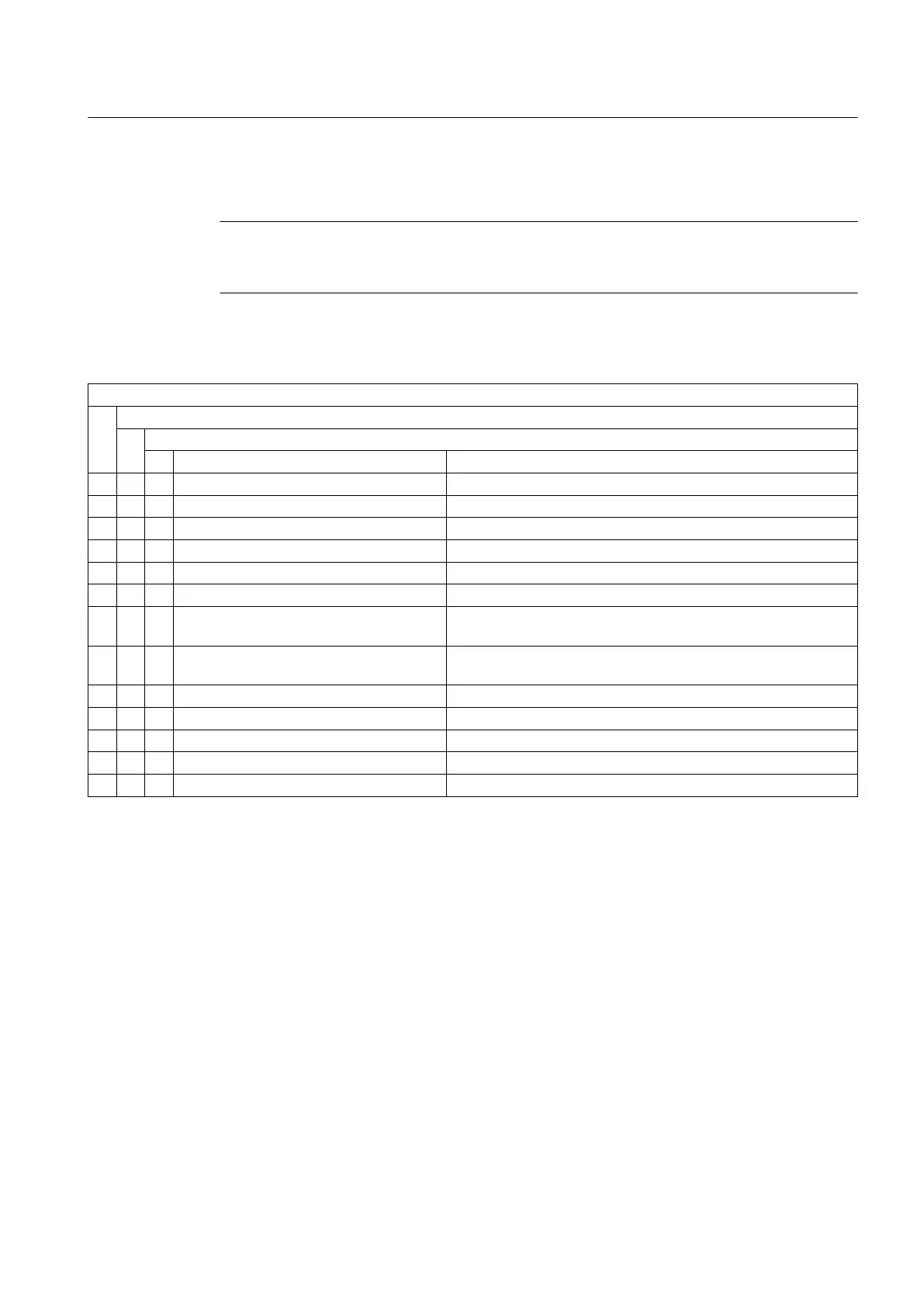

Table 8-4 Roller bearing faults

↓ Bearing overheats

↓ Bearing "whistles"

↓ Bearing "knocks"

Possible causes of faults Remedial measures

X High coupling pressure Align the machine more accurately.

X Belt tension too high Reduce the drive belt tension.

X Bearing contaminated Clean the bearing or replace it. Check the seals.

X High ambient temperature Use a suitable high-temperature grease.

X X Insufficient lubrication Grease the bearings as instructed.

X X Bearing canted Properly install the bearing.

X X Insufficient bearing play Only after consultation with the manufacturer: Fit a bearing with

greater play.

X Excessive bearing play Only after consultation with the manufacturer: Fit a bearing with

lower play.

X X Bearing corroded Replace the bearing. Check the seals.

X Too much grease in bearing Remove surplus grease.

X Wrong grease in the bearing Use the correct grease.

X Friction marks on raceway Replace the bearing.

X Scoring (brinelling) Replace the bearing. Avoid any vibration at standstill

Operation

8.9 Faults

SIMOTICS DC 1GG5

Operating Instructions 02/2016 77

Loading...

Loading...