8.9.5 Brush faults

Modify the arrangement of brush components or the brush material only with the

manufacturer's agreement.

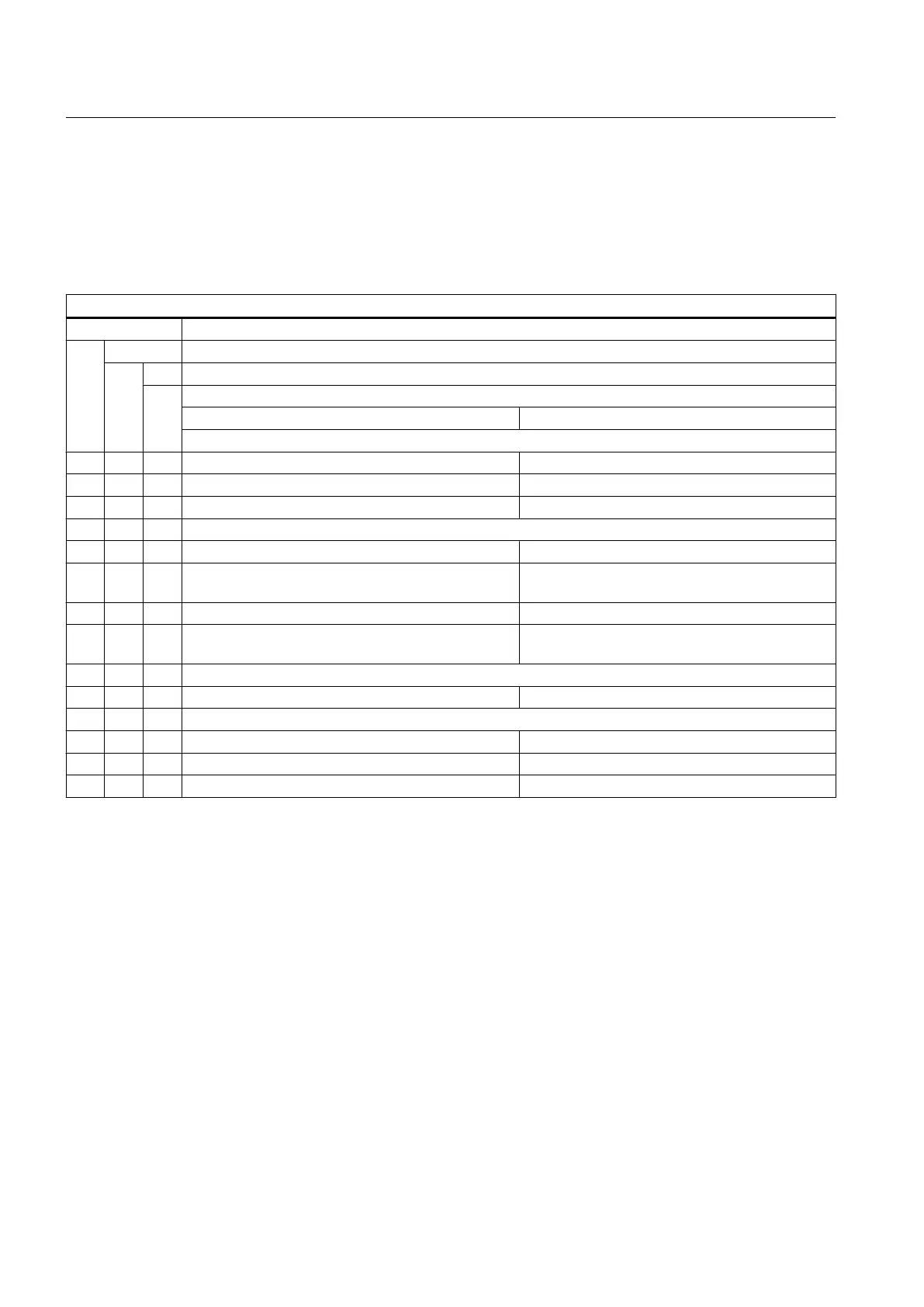

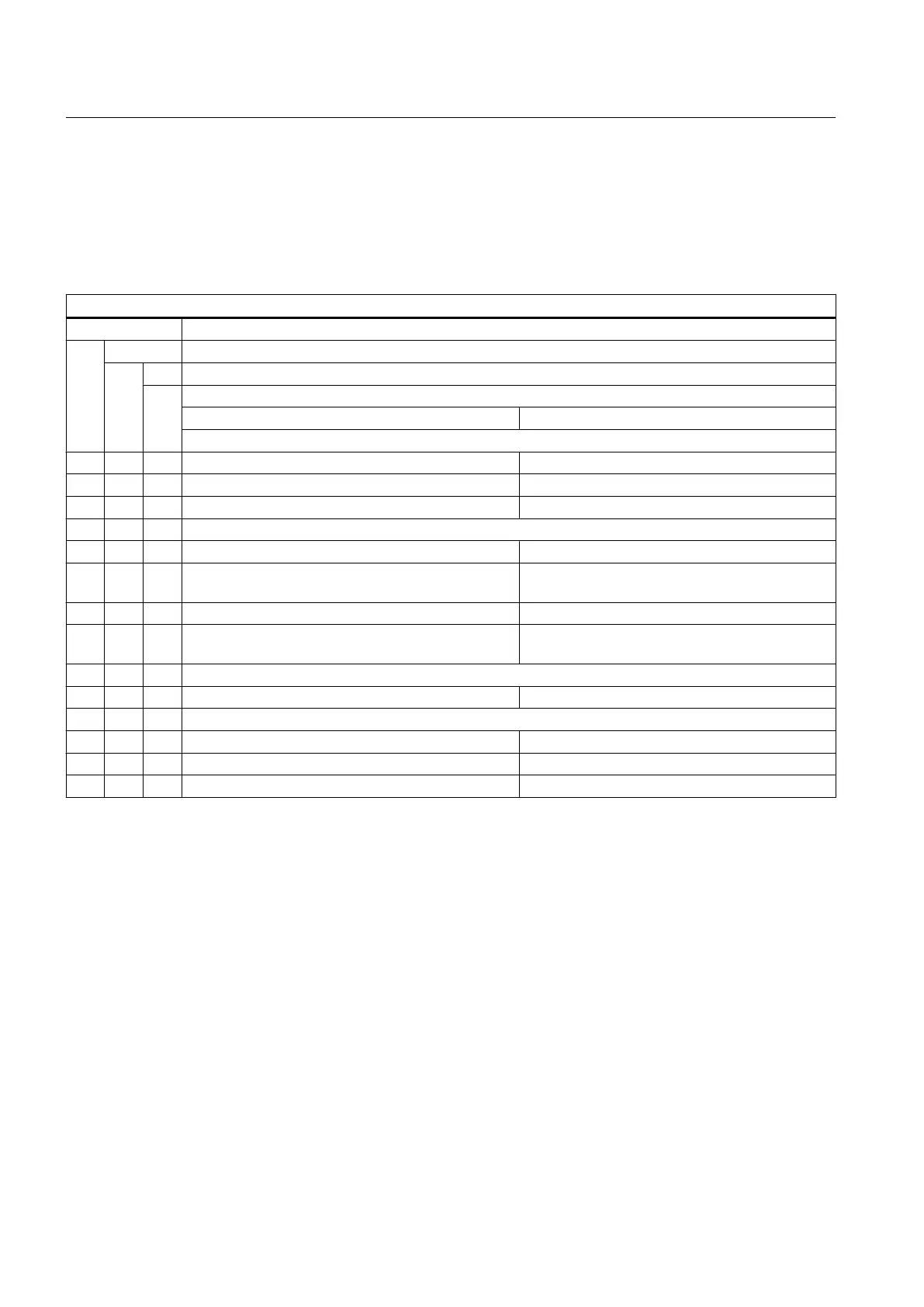

Table 8-5 Brush faults

Symptoms of fault

↓ Knocked out or shattered brush edges

↓ High degree of brush wear

↓ High degree of wear despite good commutation

Possible causes of faults Remedial measures

Plant fault

X Coupled motor out of balance Check coupling, rebalance system

X Poor alignment Align motor set

X Mechanical jolts Improve installation conditions

Cooling fault

X X X Cooling air too dry Change brush material

X X Silicone in the cooling air Remove silicone, clean machine and mounting

parts

X Cooling air contains too much dust Change air ducting, use an air filter

X Cooling-air flow rate too low (commutator tempera‐

ture too high)

Improve cooling

Brush fault

X X Incorrect or unsuitable brush material Change brush material

Component defect

X X Out-of-round commutator Overrev commutator

X X X Protruding segment insulation Pocket mill segment insulation

X Rotor imbalance Balance rotor

Operation

8.9 Faults

SIMOTICS DC 1GG5

78 Operating Instructions 02/2016

Loading...

Loading...