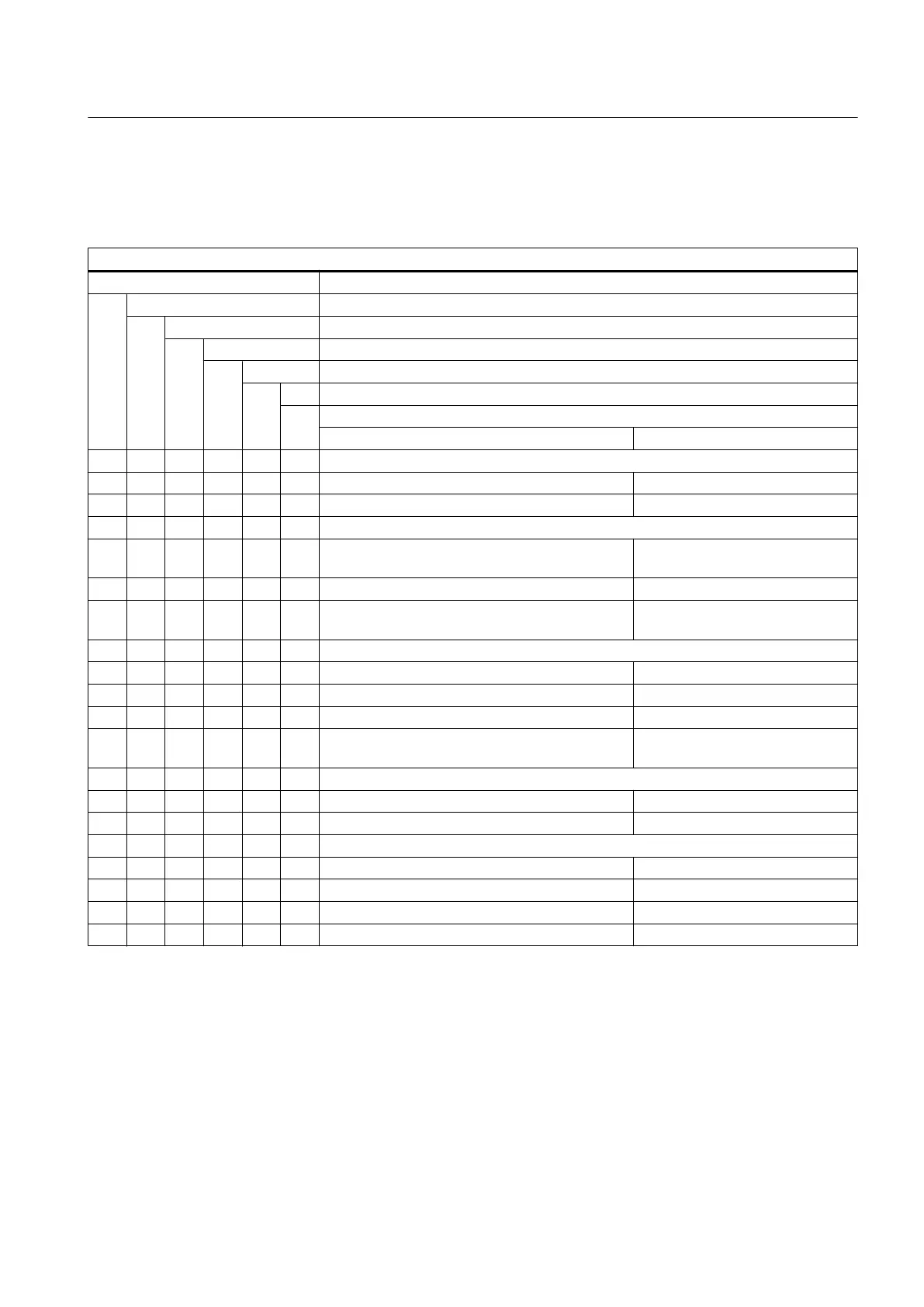

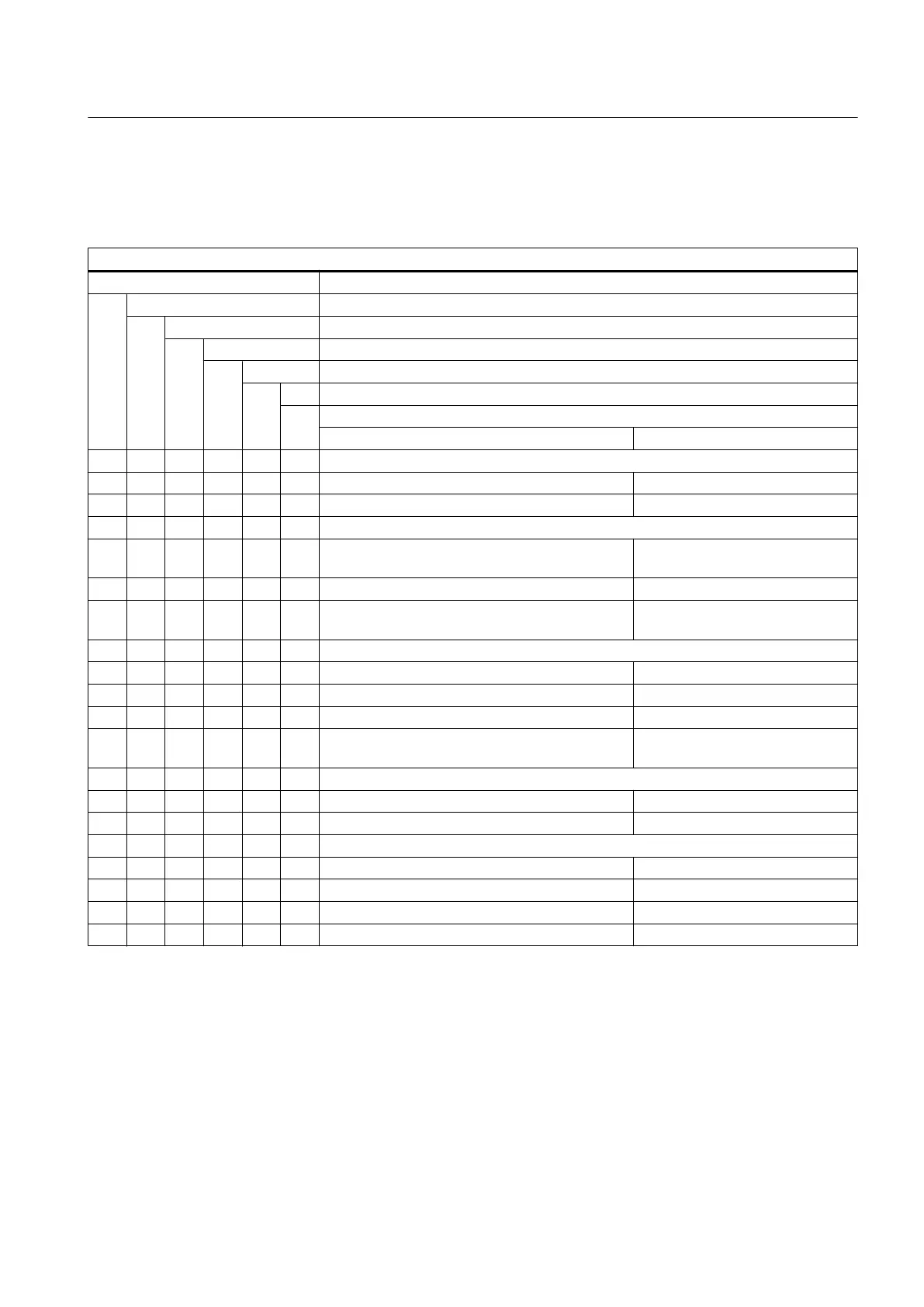

8.9.6 Commutator faults

Table 8-6 Commutator faults

Symptoms of fault

↓ Beads of molten metal

↓ Generally severe bar blackening

↓ Some segments are blackened periodically

↓ Some segments are severely scorched

↓ Flat spots on commutator

↓ Grooves in circumferential direction

Possible causes of faults Remedial measures

Plant fault

X Poor alignment Align motor set

X Mechanical jolts Improve installation

Operating mode or operating error

X Continuous light-load duty (partial load) Change number of brushes and/or

material

X Temporary overload Correct current limit

X Overload at standstill Correct current limit/shorten stand‐

still time

Cooling fault

X Cooling air too damp Change air ducting

X X Cooling air chemically aggressive Change air ducting

X Cooling air contains too much dust Change air ducting, use an air filter

X Cooling-air flow rate too high (commutator tem‐

perature too low)

Restrict air ducting (if necessary,

change brush material)

Brush fault

X Incorrect or unsuitable brush material Change brush material

X Brushes not in neutral zone Correct setting

Component defect

X Interruption in armature winding Repair winding

X Faulty solder joint Resolder solder joint

X X Out-of-round commutator Rework commutator

X Conductive inclusions in segment slots Pocket mill segment insulation

Operation

8.9 Faults

SIMOTICS DC 1GG5

Operating Instructions 02/2016 79

Loading...

Loading...