Reworking the slots

● If the commutator is skimmed, the slots should also be remachined, e.g. with a special saw.

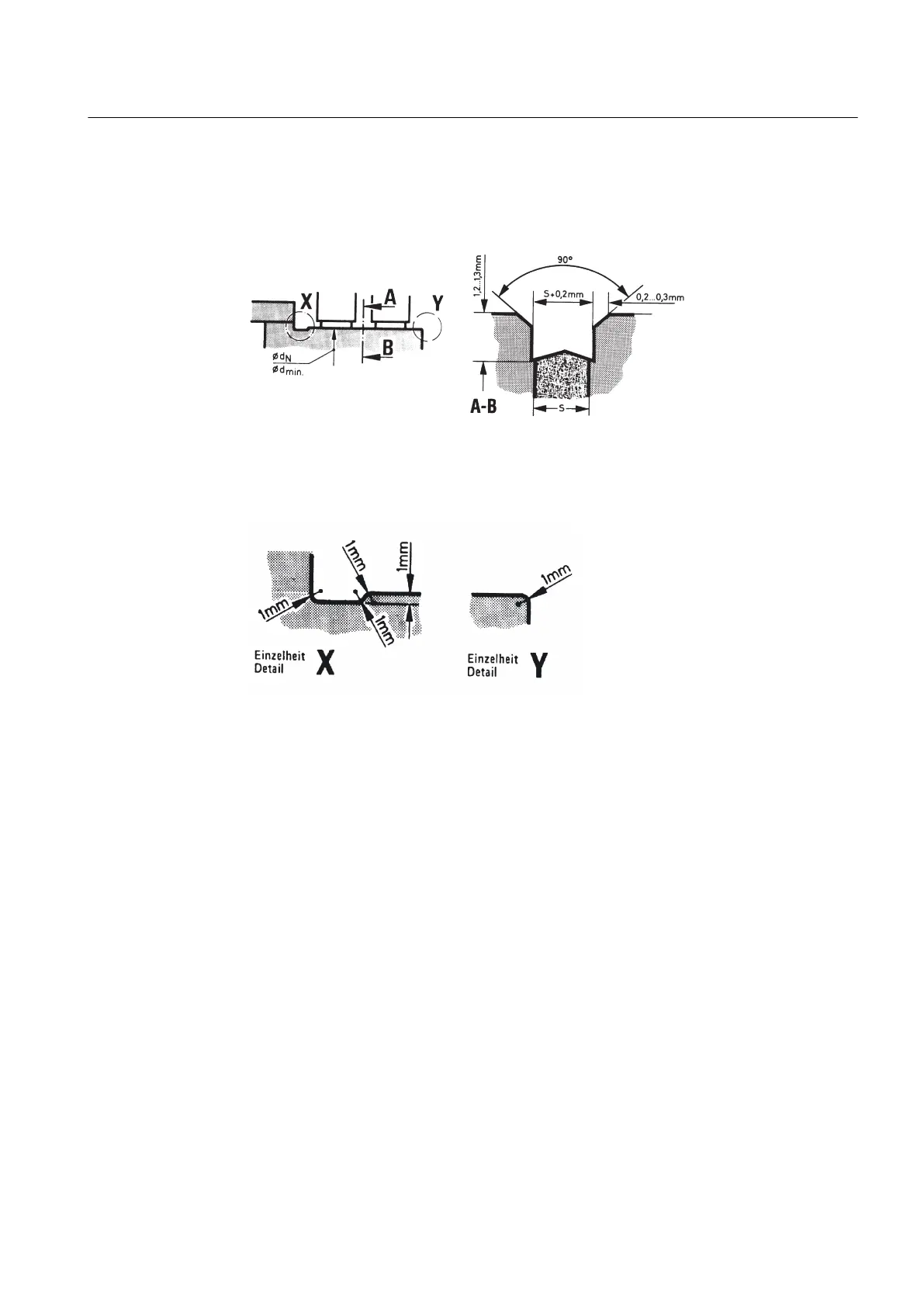

The following diagrams give the recommended slot dimensions.

Image 9-2 Reworking the slots

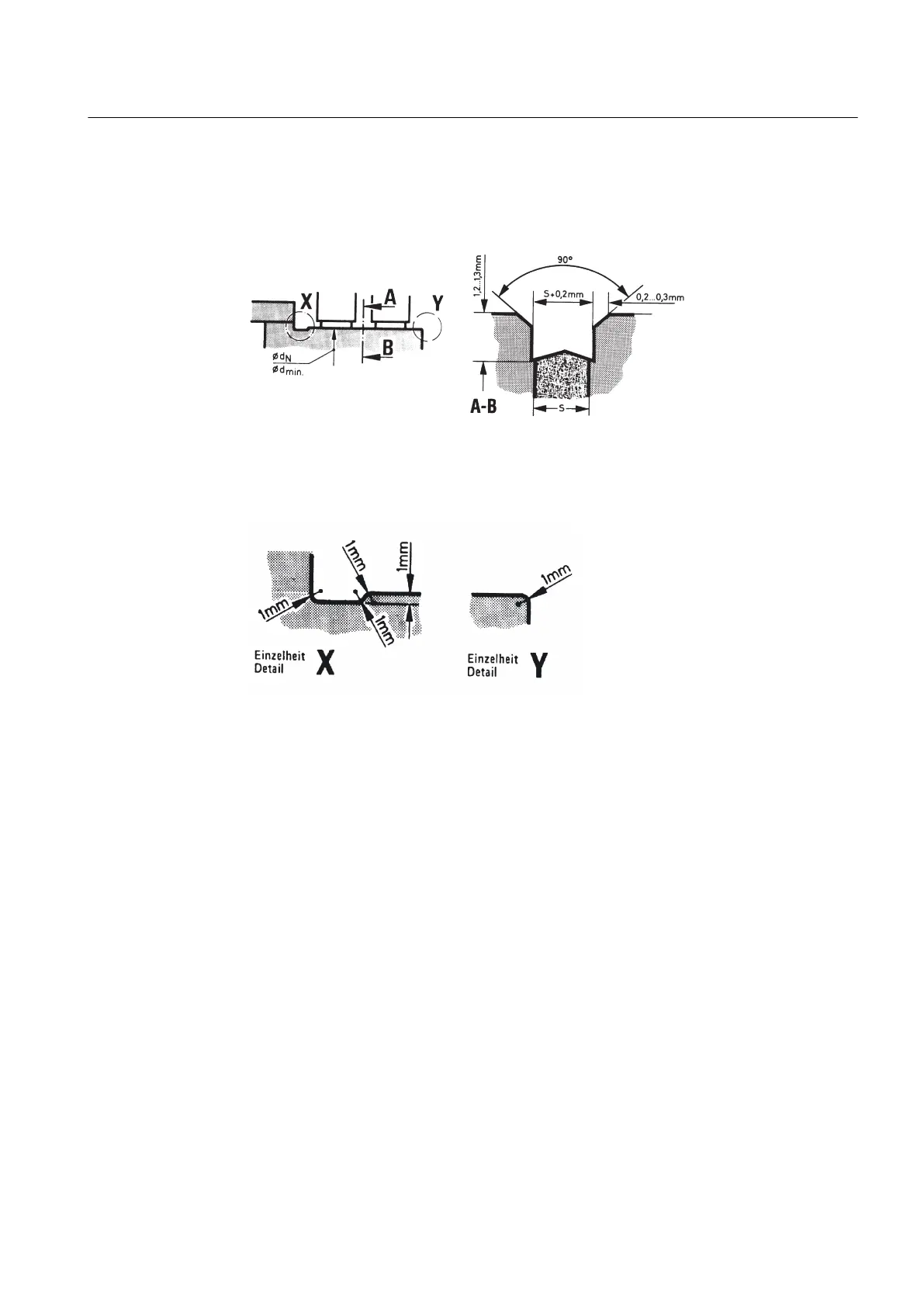

● Depending on the method used to machine the slots, it is useful to machine an undercut

as shown in the diagram below (detail X) when the commutator is skimmed. This undercut

must not be deeper than 1 mm for the smallest permissible commutator diameter.

Image 9-3 Final work on the commutator after skimming.

Final measures

● After the commutator has been reworked, adjust the brush rocker and the brush holder

(Page 89).

9.1.11 Maintaining terminal boxes

Requirement

The machine is de-energized.

Checking for tightness

● Terminal boxes must be regularly checked for tightness, undamaged insulation, and tight

terminal connections.

● If dust or humidity have infiltrated the terminal box, this should be cleaned and dried

(particularly the insulators).

Maintenance

9.1 Inspection and maintenance

SIMOTICS DC 1GG5

Operating Instructions 02/2016 91

Loading...

Loading...