Reworking the commutator after the formation of grooves

Moderate scoring or burn marks do not affect the operational reliability of the machine. The

commutator only needs to be overhauled if it is seriously scorched or grooved and/or is out-of-

round.

● Grind the commutator in the mounted position with a commutator grinder of medium grain

size, grain number 80 (210 - 177 μm).

● To do this, lift most of the brushes and operate the motor at a speed of approximately 600

rpm.

● Place the grinder on the brush holder.

Note

Suck or blow the dust out

Dust inside the motor can cause winding damage. Suck or blow the dust out.

● Remove the grinding dust with dry, oil-free compressed air. Deburr the edges of the

segments if necessary.

● Where the commutator is severely out-of-round, remove the rotor and skim the commutator

on a turning machine. You can skim the commutator down to the smallest permissible

diameter (d

min

) given in the following table.

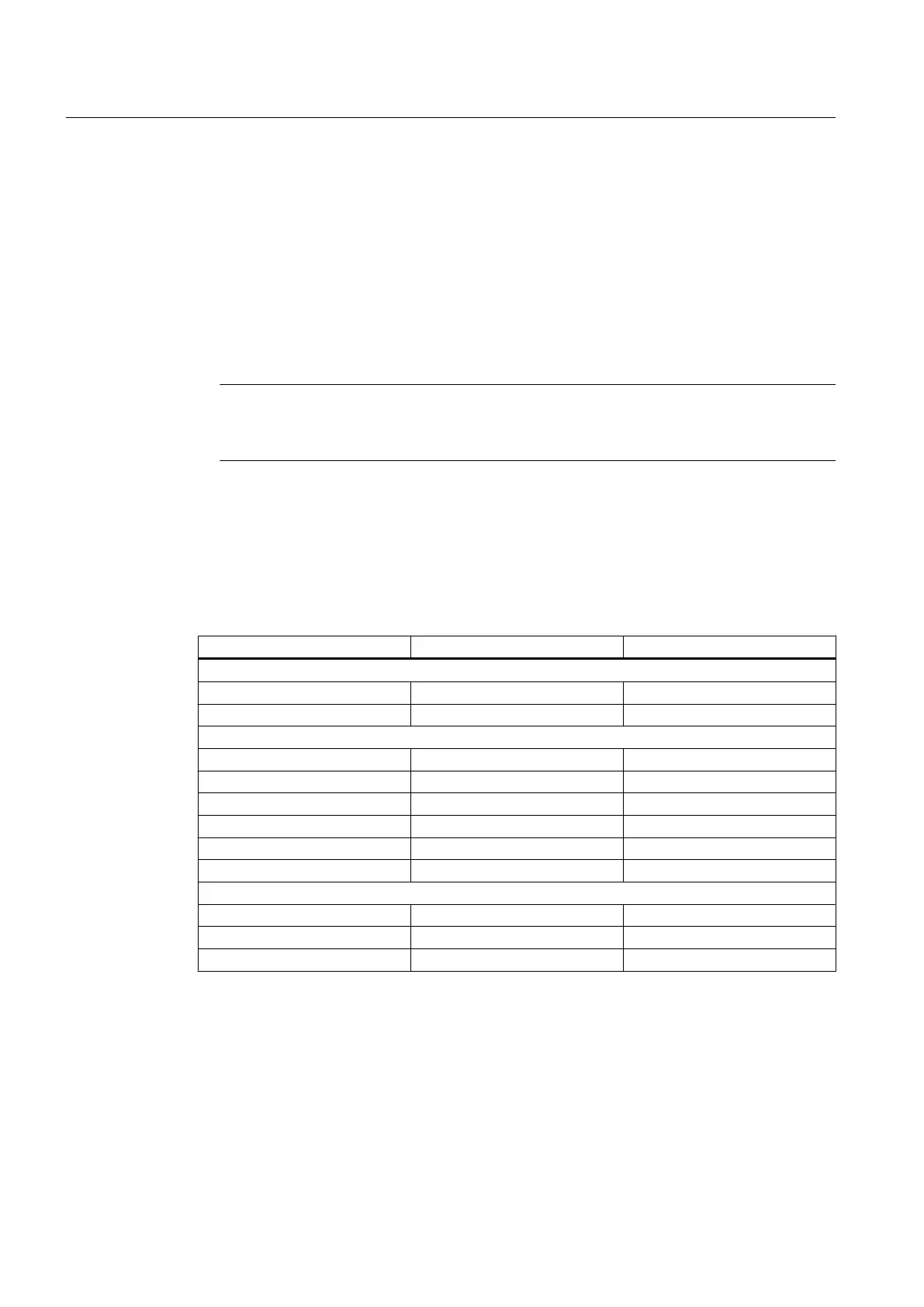

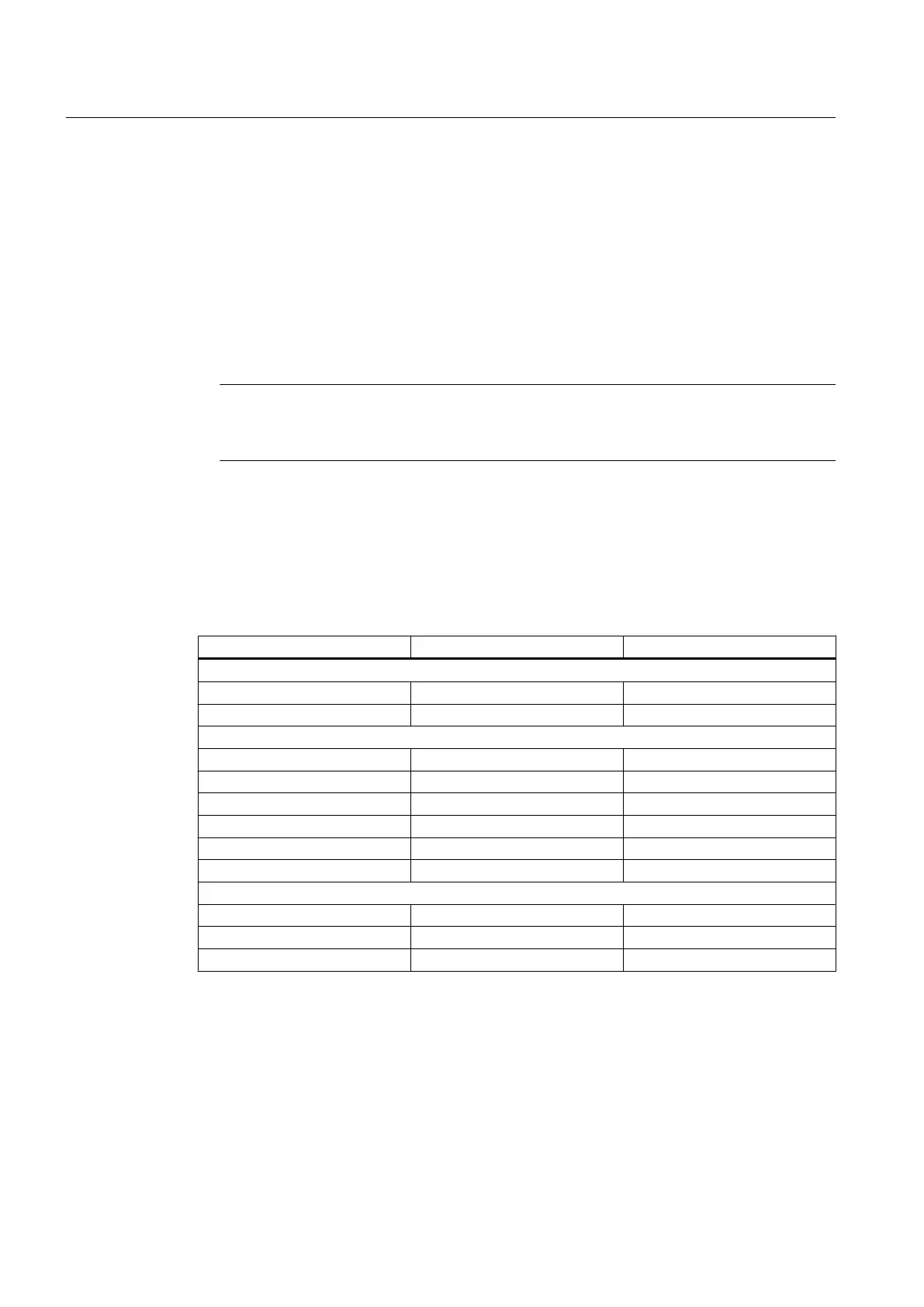

Table 9-3 Commutator overhaul – minimum permissible diameter

Shaft height Nominal diameter d

N

(mm) Minimum diameter d

min

(mm)

1G.5 / 1H.5

500 560 546

630 720 706

1G.6 / 1H.6

160 160 154

180 190 184

200 210 202

225 240 232

250 265 257

280 300 292

1G.7 / 1H.7

355 350 340

400 350 340

450 400 390

Maintenance

9.1 Inspection and maintenance

SIMOTICS DC 1GG5

90 Operating Instructions 02/2016

Loading...

Loading...